Preparation method of transition metal complex based on mixed N,O-ligand, crystal structure and application thereof

A technology of transition metals and transition metal ions, applied in organic compound/hydride/coordination complex catalysts, 1/11 group organic compounds without C-metal bonds, separation methods, etc., to achieve stable product performance and high yield High, repeatable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The chemical formula described in the present invention is C 26 h 15 N 5 o 4 Complexes of Zn [Zn(2-NCP)(3-pyc)] n The preparation method is as follows:

[0021] To Zn(NO 3 ) 3 ·6H 2 To the mixed reagent of O (0.0296g, 0.1mmol), 2-HNCP (0.0170g, 0.05mmol) and 3-Hpyc (0.0123g, 0.1mmol), add 10mL of deionized water and stir for 10min, adjust with 1mol / L NaOH solution To pH = 6.5, put in a 25mL polytetrafluoroethylene reactor, heat to 170°C for 3 days, gradually cool to room temperature, wash with deionized water and dry at room temperature to obtain yellow blocky crystals, which are transition metal Zn complexes , the yield was 56% (based on metal Zn salt). Elemental analysis: (theoretical value): C 59.27, H 2.87, N 13.29; (experimental value): C 59.22, H 2.99, N 13.25.

[0022] Relevant characterization of complexes

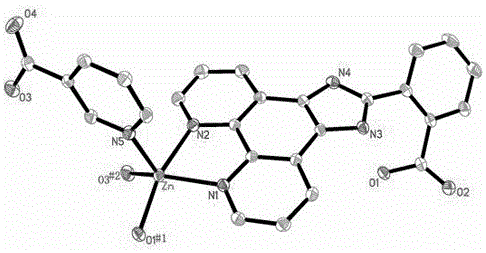

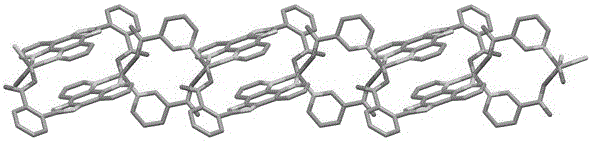

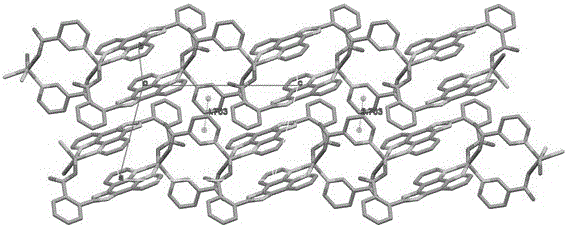

[0023] (1) Crystal structure determination of transition metal Zn complexes

[0024] The diffraction data of the complexes were collected on a Br...

Embodiment 2

[0030] The chemical formula described in the present invention is C 26 h 15 N 5 o 4 Cu complex [Cu(2-NCP)(3-pyc)] n The preparation method is as follows:

[0031] to CuCl 2 2H 2 To the mixed reagent of O (0.0170g, 0.1mmol), 2-HNCP (0.0340g, 0.1mmol) and 3-Hpyc (0.0123g, 0.1mmol), add 12mL of deionized water and stir for 8min, then use 0.5mol / L NaOH solution Adjust the pH to 7, put it in a 25mL polytetrafluoroethylene reactor, heat to 160°C for 3 days, gradually cool to room temperature, wash with deionized water and dry at room temperature to obtain green blocky crystals, which are transition metal Cu complexes. product with a yield of 48% (based on metal Cu salt). Elemental analysis: (theoretical): C, 59.48; H, 2.88; N, 13.34. (Experimental values): C, 59.40; H, 2.91; N, 13.30.

[0032] The crystal structure determination of transition metal Cu complexes is the same as that of transition metal Zn complexes. Detailed crystallographic data are shown in Table 1; import...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com