Preparation method of methyldimethoxysilane

A technology of methyldimethoxyhydrogensilane and methylhydrogendichlorosilane, which is applied in the field of preparation of methyldimethoxyhydrogensilane, can solve the problem of uneven reaction, non-release of chlorosilane, and influence on the use of downstream products, etc. problem, to achieve the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

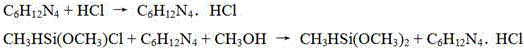

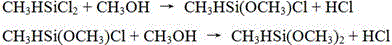

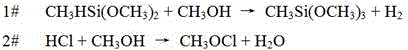

Method used

Image

Examples

Embodiment 1

[0031] Add 250g methanol to the constant pressure dropping funnel A on the upper part of the esterification packed tower, add 292g methanol to the constant pressure dropping funnel B in the three-necked flask, and add 1000g methylhydrogendichlorosilane to the constant pressure dropping funnel C in the middle of the packed tower After the material preparation is completed, turn on the magnetic stirrer, and turn on the oil margin heating device outside the three-necked flask. After the oil margin temperature reaches 70°C, start to drop methanol from the upper part of the packed tower into the packed tower at a rate of 25.0g / h. Hydrogen dichlorosilane is dripped into the middle part of the packed tower at a speed of 90g / h, and the methanol in the lower part of the packed tower is dripped into a three-necked flask at a speed of 29.2g / h to carry out the esterification reaction, and the hydrogen chloride by-product is absorbed into hydrochloric acid by tap water. To avoid overflow of...

Embodiment 2

[0033] Add 280g methanol to the constant pressure dropping funnel A on the upper part of the esterification packed tower, add 250g methanol to the constant pressure dropping funnel B in the three-necked flask, and add 1000g methylhydrogendichlorosilane to the constant pressure dropping funnel C in the middle of the packed tower After the material preparation is completed, turn on the magnetic stirrer, and turn on the oil margin heating device outside the three-necked flask. After the oil margin temperature reaches 75°C, start to drop methanol from the upper part of the packed tower into the packed tower at a rate of 28.0g / h. Hydrogen dichlorosilane is dripped into the middle part of the packed tower at a speed of 100g / h, and the methanol in the lower part of the packed tower is dripped into a three-necked flask at a speed of 25.0g / h to carry out esterification reaction, and the by-product hydrogen chloride is absorbed into hydrochloric acid by tap water. To avoid the overflow o...

Embodiment 3

[0035] Add 265g of methanol to the constant pressure dropping funnel A on the upper part of the esterification packed tower, add 270g of methanol to the constant pressure dropping funnel B of the three-necked flask, and add 1000g of methylhydrogendichlorosilane to the constant pressure dropping funnel C in the middle of the packed tower , after the material preparation is completed, turn on the magnetic stirrer, and turn on the oil margin heating device outside the three-necked flask. After the oil margin temperature reaches 80°C, start to drop methanol from the upper part of the packed tower into the packed tower at a rate of 26.5g / h. Hydrogen dichlorosilane is dripped into the middle part of the packed tower at a speed of 110g / h, and the methanol in the lower part of the packed tower is dripped into the three-necked flask at a speed of 27.0g / h to carry out the esterification reaction, and the by-product hydrogen chloride is absorbed into hydrochloric acid by tap water. To avo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com