Silicon-containing polyurethane oligomer and preparation method thereof

A technology of polyurethane oligomer and silicone oil, applied in the field of silicon-containing polyurethane oligomer and its preparation, can solve problems such as poor weather resistance, and achieve the effects of improving heat resistance, expanding application scope and overcoming poor weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

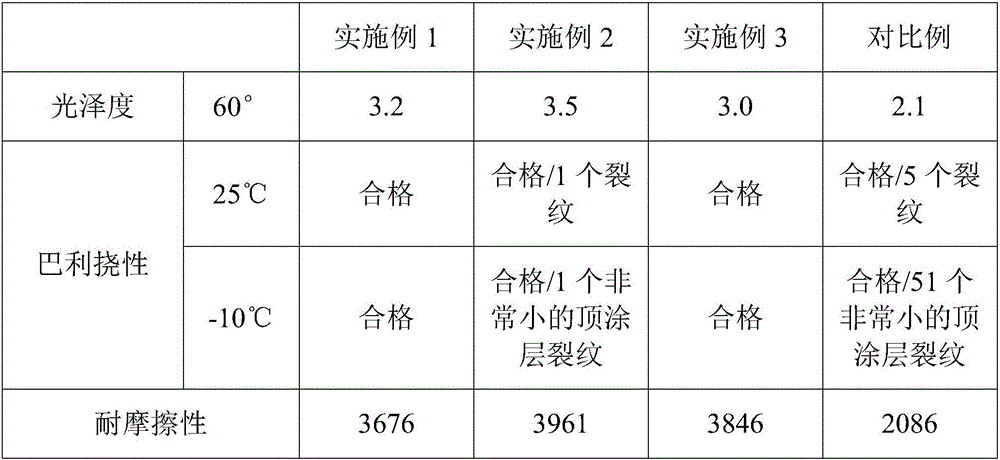

Embodiment 1

[0020] Step 1) 20 g of hydroxyl-terminated silicone oil and 350 g of polyoxypropylene glycol (molecular weight: 1000) are respectively subjected to water removal treatment;

[0021] Step 2) In the reaction kettle, add 20 g of hydroxyl-terminated silicone oil and 350 g of polyoxypropylene glycol (molecular weight: 1000) after the water removal treatment, and stir for 0.5 hours at room temperature;

[0022] Step 3) At 80°C, with a stirring rate of 90r / min, add 140g of isophorone diisocyanate and 1g of dibutyltin dilaurate into the flask, and react for 2-4 hours;

[0023] Step 4) After reacting for 2 hours, continuously measure the NCO content during the reaction process, and when the NCO content is close to the theoretical value, the silicon-containing polyurethane oligomer is obtained.

example 2

[0025] Step 1) 40g of hydroxyl-terminated silicone oil and 400g of polyoxypropylene glycol (molecular weight: 1000) are respectively subjected to water removal treatment;

[0026] Step 2) In the reaction kettle, add 40 g of hydroxyl-terminated silicone oil and 400 g of polyoxypropylene glycol (molecular weight: 1000) after the water removal treatment, and stir for 0.5 hours at room temperature;

[0027] Step 3) At 85°C, with a stirring rate of 90r / min, add 150g of isophorone diisocyanate and 1g of dibutyltin dilaurate into the flask, and react for 2-4 hours;

[0028] Step 4) After reacting for 2 hours, continuously measure the NCO content during the reaction process, and when the NCO content is close to the theoretical value, the silicon-containing polyurethane oligomer is obtained.

Embodiment 3

[0030] Step 1) 25 g of hydroxyl-terminated silicone oil and 600 g of polyoxypropylene glycol (molecular weight 2000) are respectively subjected to water removal treatment;

[0031] Step 2) In the reaction kettle, add 25g of hydroxyl-terminated silicone oil and 600g of polyoxypropylene glycol (molecular weight: 2000) after the water removal treatment, and stir for 0.5 hours at room temperature;

[0032] Step 3) At 85°C, with a stirring rate of 90r / min, add 120g of isophorone diisocyanate and 1g of dibutyltin dilaurate into the flask, and react for 2-4 hours;

[0033] Step 4) After reacting for 2 hours, continuously measure the NCO content during the reaction process, and when the NCO content is close to the theoretical value, the silicon-containing polyurethane oligomer is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com