Maleimide terminated type benzoxazine oligomer and preparation method thereof

A maleimide group, maleimide functional technology, applied in the field of benzoxazine oligomer and its preparation, to achieve the effects of simplifying synthesis process, simplifying process and shortening reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

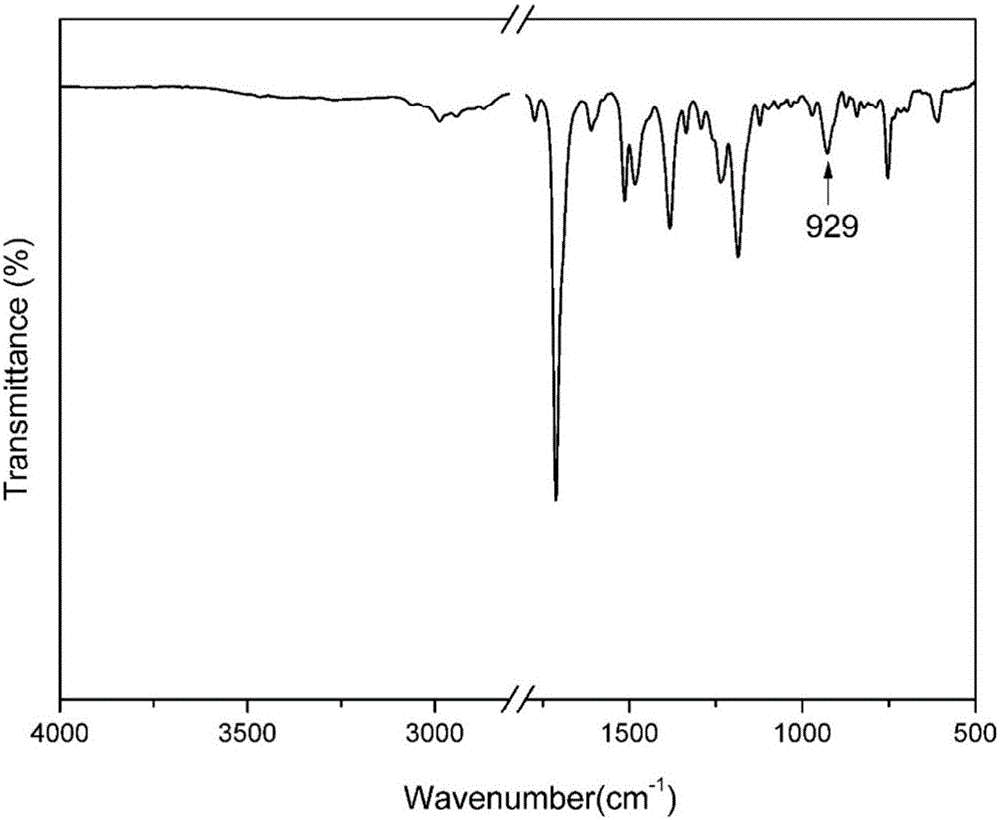

Embodiment 1

[0042] (1) Add 33.4 g of 2-aminophenol and 30.0 g of maleic anhydride to an ice bath system containing 80 mL of dimethylformamide (DMF), and then add 15 g of phosphorus pentoxide and 8 g of 95- 98% concentrated sulfuric acid, after reacting for 30 minutes, the reaction device was moved to an oil bath at 70° C. for 6 hours. After the reaction, the reaction solution was poured into 200ml of deionized water to obtain a large amount of precipitation. After the reaction solution was washed with deionized water, filtered and dried, 47.6 g of the product maleimide-functionalized phenol was obtained, with a yield of 82%. The reaction equation is as follows:

[0043]

[0044] (2) Weigh 30g of maleimide functionalized phenol obtained in the previous step, and 47.63g of 4,4-dihydroxydiphenylmethane (bisphenol F), 62.89g of 4,4-diaminodiphenylmethane , 38.10 g of paraformaldehyde, and 150 ml of toluene were respectively added to a reaction flask equipped with a stirrer, a thermometer ...

Embodiment 2

[0051] (1) 2-aminophenol in Example 1 is replaced by m-aminophenol, and other steps are the same as those in Example 1.

[0052] Wherein, the structural formula of m-aminophenol is:

[0053] (2) In the second step reaction, the amount of the reactant was changed to: Weigh 30 g of maleimide functionalized phenol obtained in the previous step, and 47.63 g of 4,4-dihydroxydiphenylmethane (bisphenol F) g, 62.89 g of 4,4-diaminodiphenylmethane, 38.10 g of paraformaldehyde, and 150 ml of toluene. 135.65 g of the product was obtained with a yield of 84%.

[0054] In the present embodiment, the structural formula of the obtained benzoxazine oligomer is:

[0055]

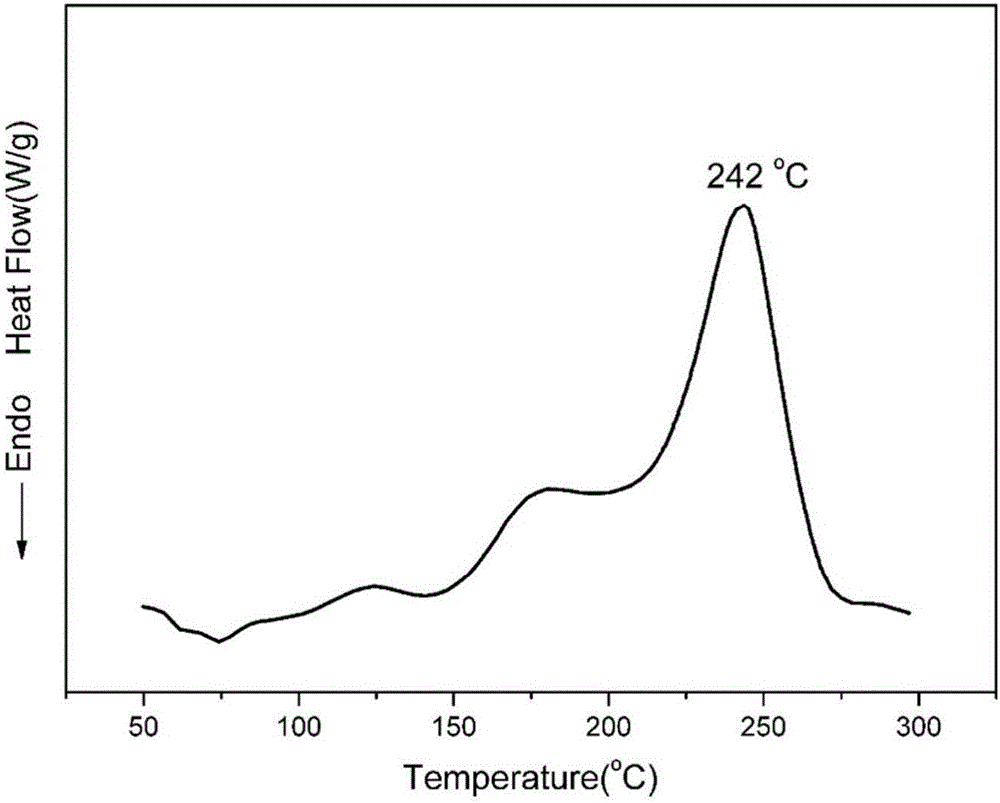

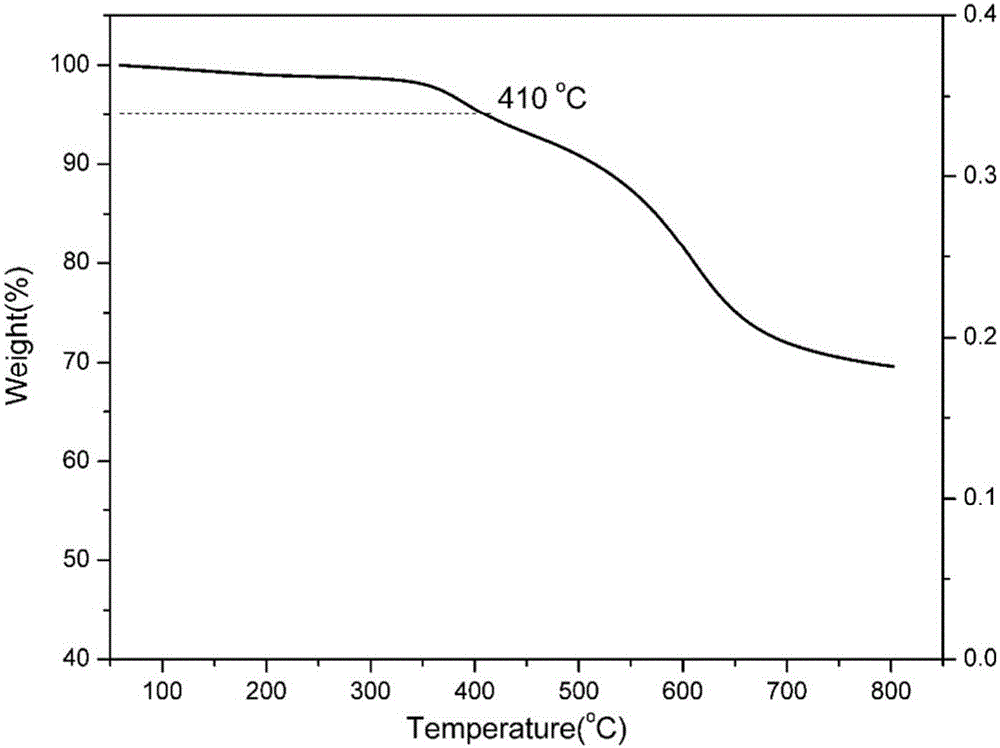

[0056] After ring-opening and solidification of the benzoxazine oligomer obtained in this example, its glass transition temperature was measured to be 293° C., its 5% thermal weight loss temperature was 397° C., and its carbon residue rate at 800° C. was 68%.

Embodiment 3

[0058] (1) 2-aminophenol in Example 1 is replaced by m-aminophenol, and other steps are the same as those in Example 1.

[0059] Wherein, the structural formula of p-aminophenol is:

[0060] (2) In the second step reaction, the amount of reactants was changed to: weigh 30 g of maleimide functionalized phenol, and 47.63 g of 4,4-dihydroxydiphenylmethane (bisphenol F), 4, 67.32g of 4-diaminobenzophenone, 38.10g of paraformaldehyde, and 150ml of xylene. 147.67 g of the product was obtained with a yield of 89%.

[0061] In the present embodiment, the structural formula of the obtained benzoxazine oligomer is:

[0062]

[0063] After ring-opening and solidification of the benzoxazine oligomer obtained in this example, its glass transition temperature was measured to be 311° C., its 5% thermal weight loss temperature was 412° C., and its carbon residue rate at 800° C. was 71%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com