Preparation method of cellulose-based oil-water separation thin film

A technology for separating membranes and cellulose, applied in semipermeable membrane separation, chemical instruments and methods, membranes, etc., can solve the problems of weak interaction between hydrophobic particles and substrates, poor stability, and easy falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

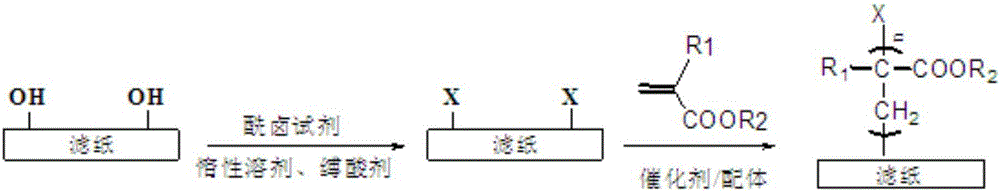

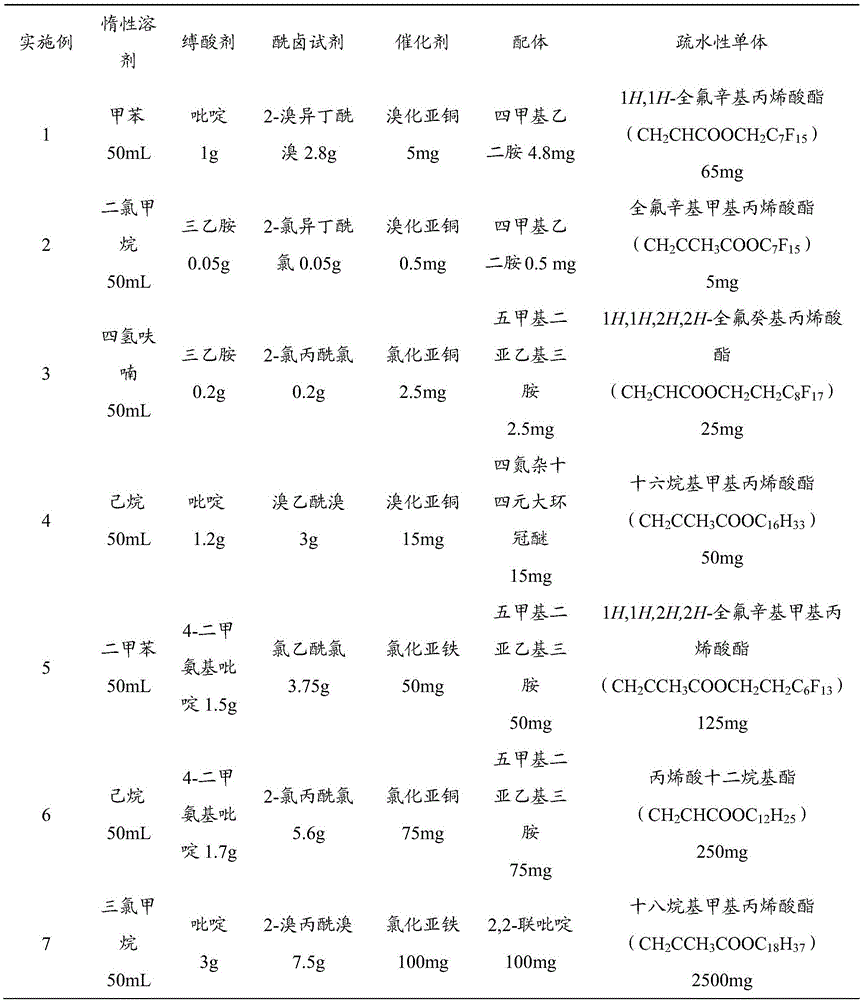

[0024] A preparation method of cellulose-based oil-water separation membrane, comprising the following steps:

[0025] (1) immerse the cellulose filter paper in an inert solvent, drop an acid-binding agent and an acyl halide reagent to react, and obtain a filter paper with a macromolecular initiator grafted on the surface;

[0026] The inert solvent is selected from any one of dichloromethane, chloroform, tetrahydrofuran, hexane, xylene, and toluene.

[0027] The acid-binding agent is any one of pyridine, triethylamine, and 4-dimethylaminopyridine, and the mass ratio is acid-binding agent: filter paper = 0.1-6: 1, preferably acid-binding agent: filter paper = 0.4-3 :1.

[0028] The acyl halide reagent is any one of 2-bromoisobutyryl bromide, 2-chloroisobutyryl chloride, chloroacetyl chloride, bromoacetyl bromide, 2-chloropropionyl chloride, 2-bromopropionyl bromide, and the acyl The mass ratio of the halogen reagent to the filter paper is 0.1-15:1, preferably 0.4-6:1.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com