Carbon nanotube-nano-crystalline cellulose-polyvinyl alcohol composite conductive gel and preparation method and application thereof

A technology of nanocellulose and carbon nanotubes, which is applied in the field of carbon nanotube-nanocellulose-polyvinyl alcohol composite conductive gel and its preparation, can solve the problem of carbon nanotube-nanotube-nanometer which does not have good mechanical properties and electrical conductivity. cellulose-polyvinyl alcohol composite conductive gel, etc., to achieve the effect of enhancing mechanical properties, simple process flow, and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

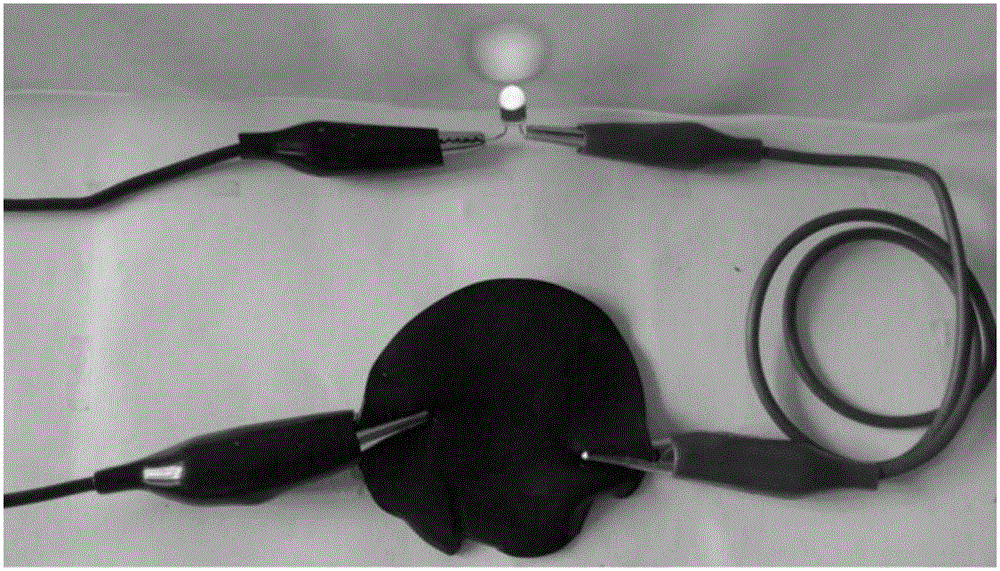

Examples

Embodiment 1

[0060] Step 1, the preparation of carbon nanotube dispersion liquid and nanocellulose suspension, its specific method step comprises:

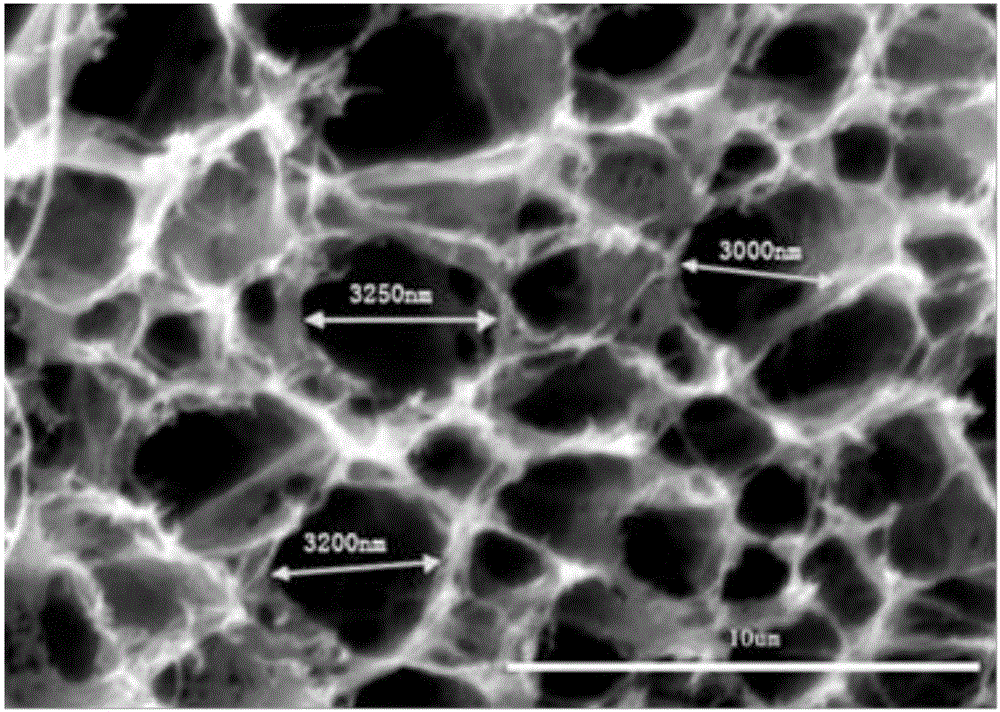

[0061] (1) Prepare an aqueous solution of sodium dodecylbenzenesulfonate with a mass fraction of 1%. (2) Add multilayer-walled carbon nanotubes and ultrasonically disperse for 10 minutes at a power of 700w to prepare a carbon nanotube dispersion with a mass fraction of 0.35%, which is stored for future use. (3) Take 20 g of pulverized absorbent cotton and add it to 400 g of sulfuric acid with a mass fraction of 48%, and carry out acidolysis under magnetic stirring in a constant temperature water bath at 45°C. (4) After 60 minutes, deionized water was added to terminate the acid hydrolysis reaction, and the resulting mixture was rinsed repeatedly with deionized water, and then transferred to a dialysis bag for dialysis for 3 days until the pH was neutral. (5) Ultrasonic pulverize the above mixture for 150 minutes at a power of 900w, and then a...

Embodiment 2

[0065] Step 1, the preparation of carbon nanotube dispersion liquid and nanocellulose suspension, its specific method step comprises:

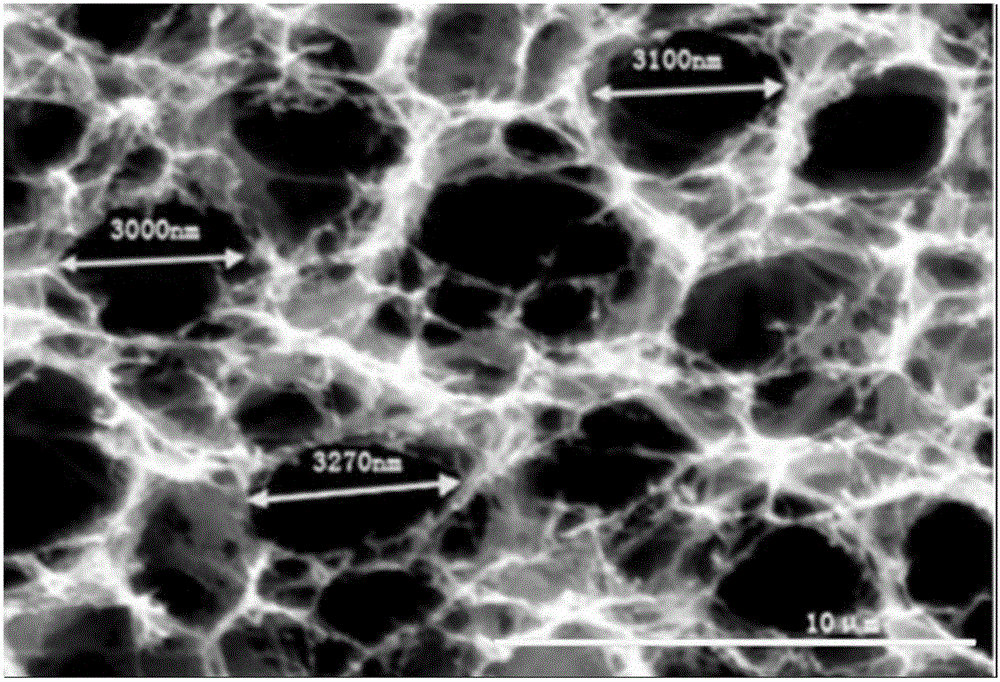

[0066] (1) Prepare an aqueous solution of sodium dodecylbenzenesulfonate with a mass fraction of 1%. (2) Add multilayer-walled carbon nanotubes, ultrasonically disperse for 10 minutes at a power of 700w, and prepare a carbon nanotube dispersion with a mass fraction of 0.35%, and store it for future use. (3) Take 20 g of pulverized absorbent cotton and add it to 400 g of sulfuric acid with a mass fraction of 48%, and carry out acidolysis under magnetic stirring in a constant temperature water bath at 45°C. (4) After 60 minutes, deionized water was added to terminate the acid hydrolysis reaction, and the resulting mixture was rinsed repeatedly with deionized water, and then transferred to a dialysis bag for dialysis for 3 days until the pH was neutral. (5) Ultrasonic pulverize the above mixture for 150 minutes at a power of 900w, and then adjus...

Embodiment 3

[0070] Step 1, the preparation of carbon nanotube dispersion liquid and nanocellulose suspension, its specific method step comprises:

[0071] (1) Prepare an aqueous solution of sodium dodecylbenzenesulfonate with a mass fraction of 1%. (2) Add multilayer-walled carbon nanotubes and ultrasonically disperse for 10 minutes at a power of 700w to prepare a carbon nanotube dispersion with a mass fraction of 0.35%, which is stored for future use. (3) Take 20 g of pulverized absorbent cotton and add it to 400 g of sulfuric acid with a mass fraction of 48%, and carry out acidolysis under magnetic stirring in a constant temperature water bath at 45°C. (4) After 60 minutes, deionized water was added to terminate the acid hydrolysis reaction, and the resulting mixture was rinsed repeatedly with deionized water, and then transferred to a dialysis bag for dialysis for 3 days until the pH was neutral. (5) Ultrasonic pulverize the above mixture for 150 minutes under the power of 900w, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com