Reflection crack resistant, low noise, highly durable asphalt mixture and its thin layer surfacing pavement method

A durable and low-noise technology, applied in asphalt material adhesives, polymer adhesive additives, on-site cohesive pavements, etc., can solve the problems of reduced durability, low economic efficiency, and waste reuse. problem, to achieve the effect of improving durability and low noise function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Specific examples are given below to describe the present invention in more detail. However, the scope of the present invention is not limited to the descriptions of the Examples, and it is obvious to those skilled in the art to which the present invention pertains.

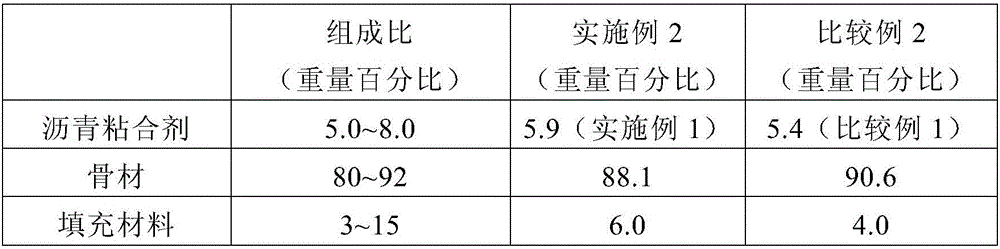

[0065] Table 2 lists the composition ratios of asphalt binders using the above-mentioned asphalt additives of the present invention. What did not add the additive of this invention was used as a comparative example.

[0066] Table 2

[0067] Composition ratio (weight percent) Example 1 Comparative example 1 Additives of the present invention 2~6 3.5 - Modified asphalt 94~98 96.5 100

[0068] In the asphalt binder of the present invention, when the additive is less than 2% by weight, it is difficult to give full play to the function of the additive; when it exceeds the range of 6% by weight, excessive fluidity will cause the binder to break down. The physical propertie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com