A kind of antibacterial pbat/pla composite film and preparation method thereof

A composite film, antibacterial technology, applied in the field of antibacterial PBAT/PLA composite film and its preparation, to achieve the effects of avoiding penetration, good light stability, antibacterial and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

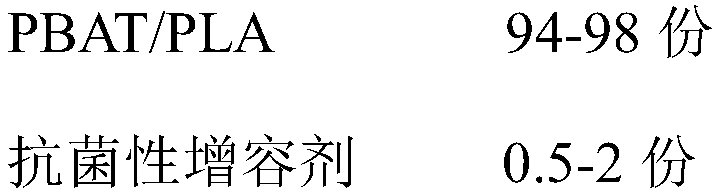

[0049] An antibacterial PBAT / PLA composite film, comprising the following components and parts by weight:

[0050]

[0051] Wherein in the PBAT / PLA each component and parts by weight are:

[0052] PBAT (molecular weight 80,000) 80 parts

[0053] 40 parts of PLA (80,000 molecular weight).

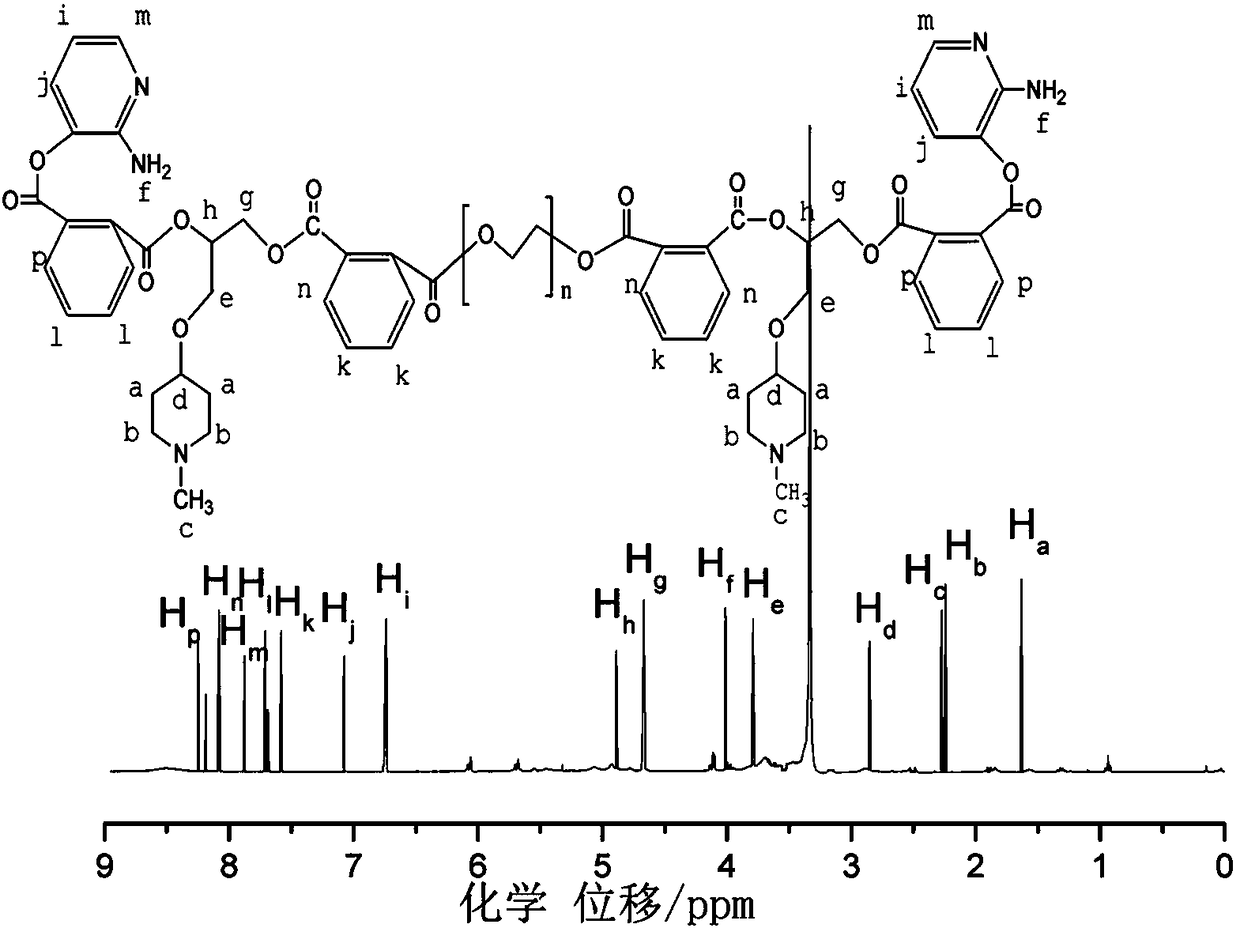

[0054] Wherein the antibacterial compatibilizer is:

[0055]

[0056] Among them, R is -CH 3 or -CH 2 CH 3 .

[0057] A preparation method for an antibacterial PBAT / PLA composite film, comprising the steps of:

[0058] (1) Weigh the raw materials according to the parts by weight of the above components, and dry the PLA particles and PBAT particles in a vacuum drying oven at 70°C for 3-5h;

[0059] (2) Mix the dried PLA granules, PBAT granules, antibacterial compatibilizer, tetrabutyl titanate and lubricant in proportion and then add them to the twin-screw extruder for extrusion granulation, set the extruder The temperature in each zone is between 170-185°C;

[0060] (3) Add th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com