Low-addition ultra-light superconductivity flame-retardant PPO (polyphenylene oxide) alloy and preparation method thereof

A superconducting and alloy technology, which is applied in the field of alloy preparation technology and PPO alloy preparation technology, can solve the problems of poor physical properties, pollution, large addition ratio and large addition amount, etc., and achieves good flame retardant performance, small machine wear, and improved impact. Effects of performance and cold resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

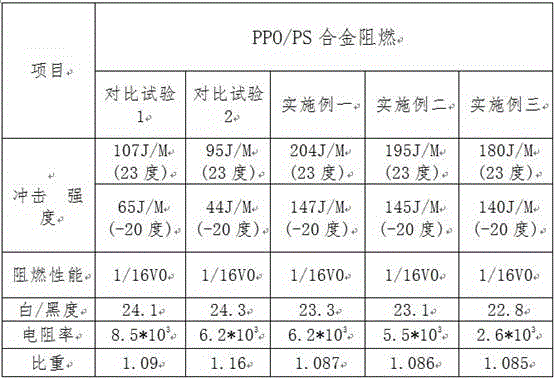

Examples

Embodiment 1

[0015] A low-addition, ultra-light superconducting flame-retardant PPO alloy, comprising the following components by weight: 50 parts of polyphenylene ether, 16 parts of polystyrene, 5 parts of triphenylphosphine oxide, 5 parts of carbon nanotubes, and 0.2 parts of antioxidant 1 part, 1 part of silicone powder, 3 parts of SEBS, 0.5 part of PETS. Wherein, the antioxidant is formed by mixing antioxidant 1098 and antioxidant 168 in a ratio of 1:2.

[0016] Its preparation process is as follows:

[0017] (1) Baking material: bake each component at 95-110 degrees for 1-2 hours;

[0018] (2) High-speed stirring: First stir the PPO powder, add 500ml of silicone oil, stir for 1-2 minutes, then add antioxidants, lubricants, carbon nanotubes and other additives and stir for 1-2 minutes, then add triphenyl Phosphorus oxide and SEBS were stirred for 3-5 minutes;

[0019] (3) Extrusion: Co-directed parallel twin-screw extrusion is adopted, the temperature setting range is 280-310 degree...

Embodiment 2

[0023] A low-addition, ultra-light superconducting flame-retardant PPO alloy, comprising the following components by weight: 60 parts of polyphenylene ether, 24 parts of polystyrene, 7 parts of triphenylphosphine oxide, 6 parts of carbon nanotubes, and 0.6 parts of antioxidant parts, silicone powder 2 parts, SEBS 5 parts, PETS 0.7 parts. Wherein, the antioxidant is formed by mixing antioxidant 1098 and antioxidant 168 in a ratio of 1:2.

[0024] Its preparation process is the same as that in Example 1.

Embodiment 3

[0026] A low-addition, ultra-light superconducting flame-retardant PPO alloy, comprising the following components by weight: 70 parts of polyphenylene ether, 28 parts of polystyrene, 8 parts of triphenylphosphine oxide, 8 parts of carbon nanotubes, and 1 part of antioxidant parts, silicone powder 3 parts, SEBS 8 parts, PETS 0.9 parts. Wherein, the antioxidant is formed by mixing antioxidant 1098 and antioxidant 168 in a ratio of 1:2.

[0027] Its preparation process is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com