Whole oil-based drilling fluid viscosifier and preparation method thereof

A drilling fluid and all-oil-based technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems affecting the use of low-density all-oil-based drilling fluids, and cannot achieve viscosity increase and cutting, and achieve improvement The effects of rheological properties, high dynamic shear force, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

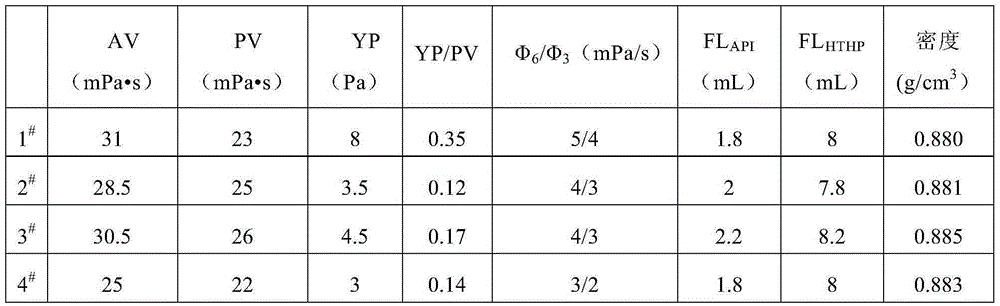

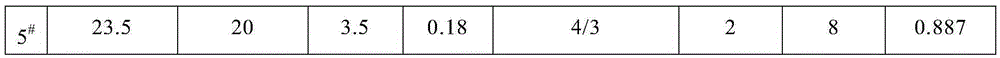

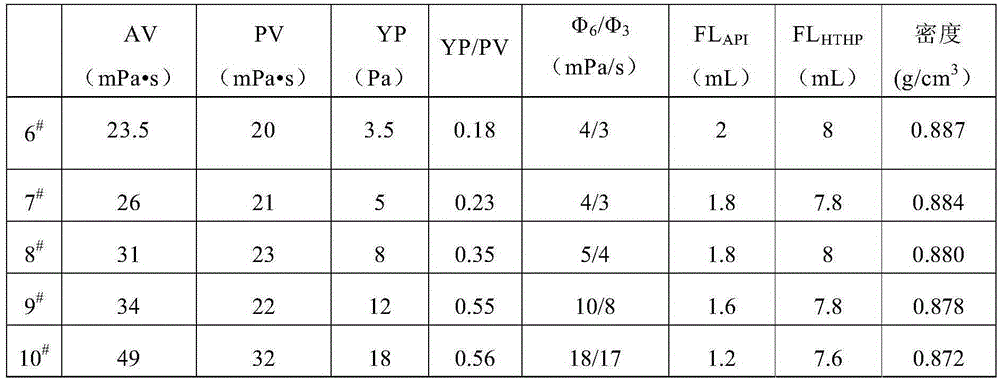

Examples

Embodiment 1

[0031] 1) Preparation of polyester polyol

[0032] In the autoclave, add 80g of n-butanol and 180g of phthalic anhydride, blow nitrogen for 10min to get rid of the air in the reaction environment, and then under the condition of nitrogen protection, control the stirring rate to 2000r / min to raise the temperature of the system to 100°C until the reaction The system is a transparent solution, then add 0.6g of p-toluenesulfonic acid, react for 1 hour, raise the temperature to 180°C, continue the reaction for 2 hours, then stop the reaction, cool down, and seal the prepared polyester polyol for storage.

[0033] 2) Preparation of tackifier

[0034] At room temperature, 40 g of the polyester polyol prepared above, 10 g of sulfoisophthalate and 240 g of toluene were added to the reaction kettle, and mixed uniformly to obtain a mixture;

[0035] Raise the temperature of the above mixture to 55°C, control the stirring rate to 2000r / min, add 80g of cyclohexyl isocyanate dropwise at a ...

Embodiment 2

[0038] 1) Preparation of polyester polyol

[0039] In the autoclave, add 80g of ethylene glycol and 150g of adipic acid, feed argon for 10 minutes to get rid of the air in the reaction environment, then under the condition of argon protection, control the stirring rate to 2500r / min to raise the temperature of the system to 120 ℃, until the reaction system is a transparent solution, then add 0.8g titanium tetraisopropoxide, react for 1 hour, then raise the temperature to 160 ℃, stop the reaction after continuing the reaction for 2 hours, cool down, and seal the prepared polyester polyol for storage.

[0040] 2) Preparation of tackifier

[0041] At room temperature, 20 g of the polyester polyol prepared above, 4 g of sulfoisophthalate and 100 g of ethyl acetate were added to the reaction kettle, and mixed uniformly to obtain a mixture;

[0042] Raise the temperature of the above mixture to 40°C, control the stirring rate to 2000r / min, add 32g of toluene diisocyanate dropwise at...

Embodiment 3

[0045] 1) Preparation of polyester polyol

[0046] In the autoclave, add 40g of the mixture of ethylene glycol and 1,2-butanediol and 50g of the mixture of adipic acid and sebacic acid, feed argon for 10min to get rid of the air in the reaction environment, and then protect the mixture under argon Under certain conditions, control the stirring rate to 3000r / min to raise the temperature of the system to 100°C until the reaction system is a transparent solution, then add 0.3g of benzoyl peroxide, react for 1 hour, heat up to 200°C, continue the reaction for 4 hours, then stop the reaction , cooled, and the prepared polyester polyol is sealed and preserved.

[0047] 2) Preparation of tackifier

[0048] At room temperature, 15 g of the mixture of polyester polyol, diamide and sulfoisophthalate, 140 g of the mixture of ethyl acetate and ethanol, and 140 g of the mixture of polyester polyol, diamide and sulfoisophthalate prepared above were added to the reaction kettle, and mixed u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com