BiPO4: Eu<3+> fluorescent powder synthesized with help of surfactant CTAB (Cetyltrimethyl Ammonium Bromide) and method for synthesizing BiPO4: Eu<3+> fluorescent powder

A technology of surfactants and phosphors, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of low crystallinity and low luminous intensity of phosphors, and achieve improved luminous performance, high luminous intensity, and simple process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the present invention comprises the following steps:

[0033] (1) Take Bi(NO 3 ) 3 ·5H 2 O, 0.1mol / L Eu(NO 3 ) 3 solution, 0~0.6mol / L CTAB solution and 0.2mol / L NH 4 h 2 PO 4 solution, for later use; CTAB solution is to add CTAB to deionized water, heat to 40-50°C and stir for 20-30min to dissolve it, and wait for it to cool to room temperature for later use;

[0034] (2) Take step 1) spare Bi(NO 3 ) 3 ·5H 2 O and Eu(NO 3 ) 3 Mix the solutions, dissolve them in a nitric acid solution with a volume fraction of 13% to 13.6%, and stir for 10 to 15 minutes to obtain a mixed solution A uniformly. Then add CTAB solution dropwise to mixed solution A to obtain mixed solution B, and stir for 20-30 minutes to generate Bi x Eu 1-x NO 3 , and then add NH dropwise to the mixed solution B 4 h 2 PO 4 solution, continue to stir for 20-30min until the reagent is fully dissolved to obtain a mixed solution C; where Bi(NO 3 ) 3 , Eu(NO 3 ) 3 ...

Embodiment 1

[0041] (1) to Bi(NO 3 ) 3 ·5H 2 Add 0.1mol / L Eu(NO 3 ) 3 Mix the solution thoroughly, then dissolve it in 10mL nitric acid solution with a volume fraction of 13%, and stir it magnetically for 15 minutes to obtain a mixed solution A;

[0042] (2) Weigh 1mmol CTAB and put it into 10mL deionized water, heat and stir to dissolve it, and obtain a CTAB solution with a concentration of 0.1mol / L; after it is cooled to room temperature, slowly add it to the mixed solution obtained in step (1) A, and additionally stirred for 30min to obtain mixed solution B;

[0043] (3) Weigh 4mmolNH 4 h 2 PO 4 Dissolved in 20mL deionized water to prepare 0.2mol / L NH 4 h 2 PO 4 Solution, it is added dropwise in the mixed solution B of step (2) gained, stirs 30min, guarantees that it mixes evenly, obtains mixed solution C; Wherein Bi(NO 3 ) 3 , Eu(NO 3 ) 3 , nitric acid solution, CTAB and NH 4 h 2 PO 4 The ratio is 0.95mmol:0.05mmol:2.5mL:0.25mmol:1mmol.

[0044] (4) adjust the pH of t...

Embodiment 2

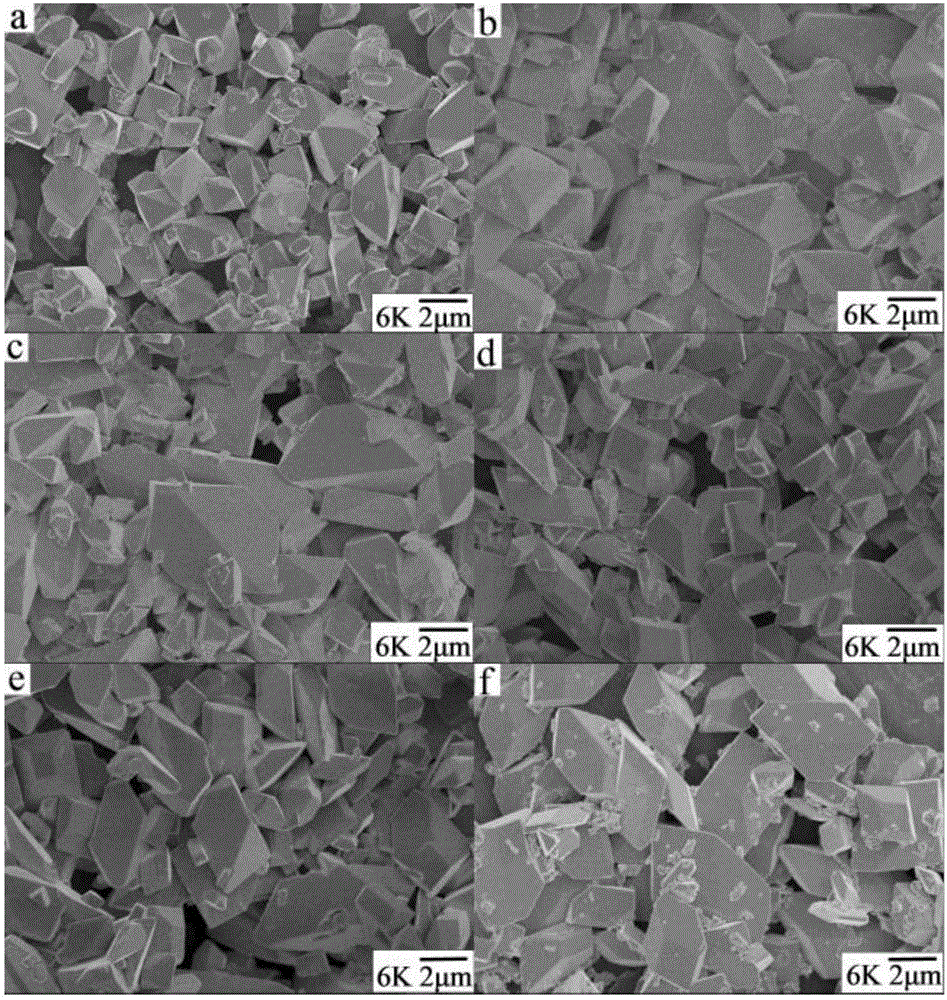

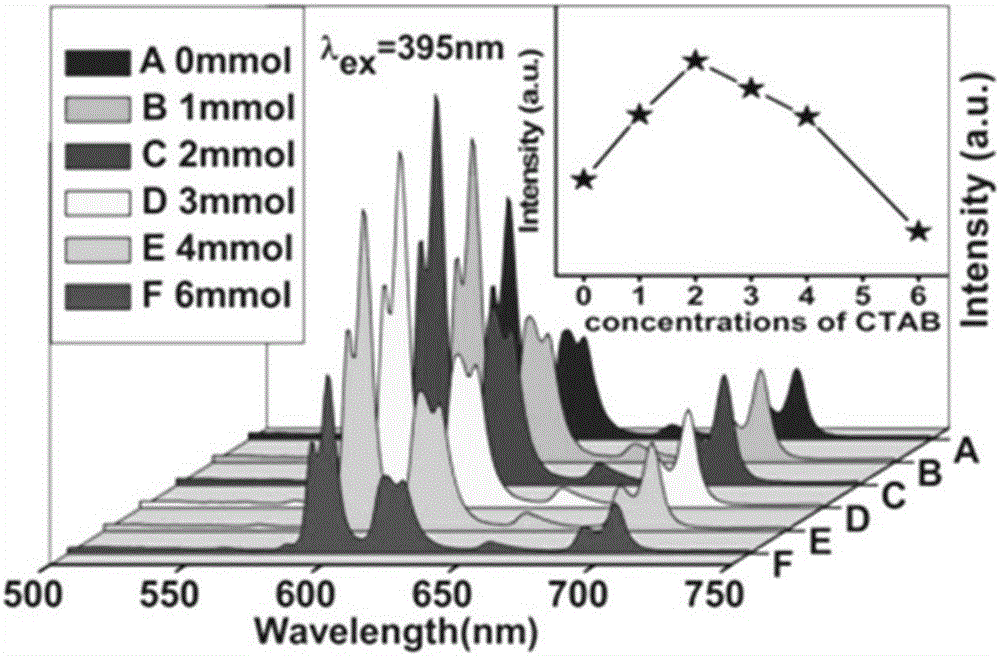

[0048] Since the previous research on the amount of CTAB added has proved that adding too much CTAB will result in samples with a hexagonal phase structure that is not conducive to enhancing the luminescence performance, so this example studies the impact of CTAB on the morphology, structure and luminescence performance by changing the amount of CTAB added. Impact.

[0049] Replace the CTAB solution with a concentration of 0.1mol / L with CTAB solutions with a concentration of 0mol / L, 0.2mol / L, 0.3mol / L, 0.4mol / L, and 0.6mol / L, and slowly add them to the mixed solution A ; Other conditions are the same as in Example 1. At this time CTAB and NH 4 h 2 PO 4 The ratios are 0, 0.5, 0.75, 1 and 1.5, respectively.

[0050] Where the concentration of CTAB solution is 0mol / L, 10mL deionized water is added directly.

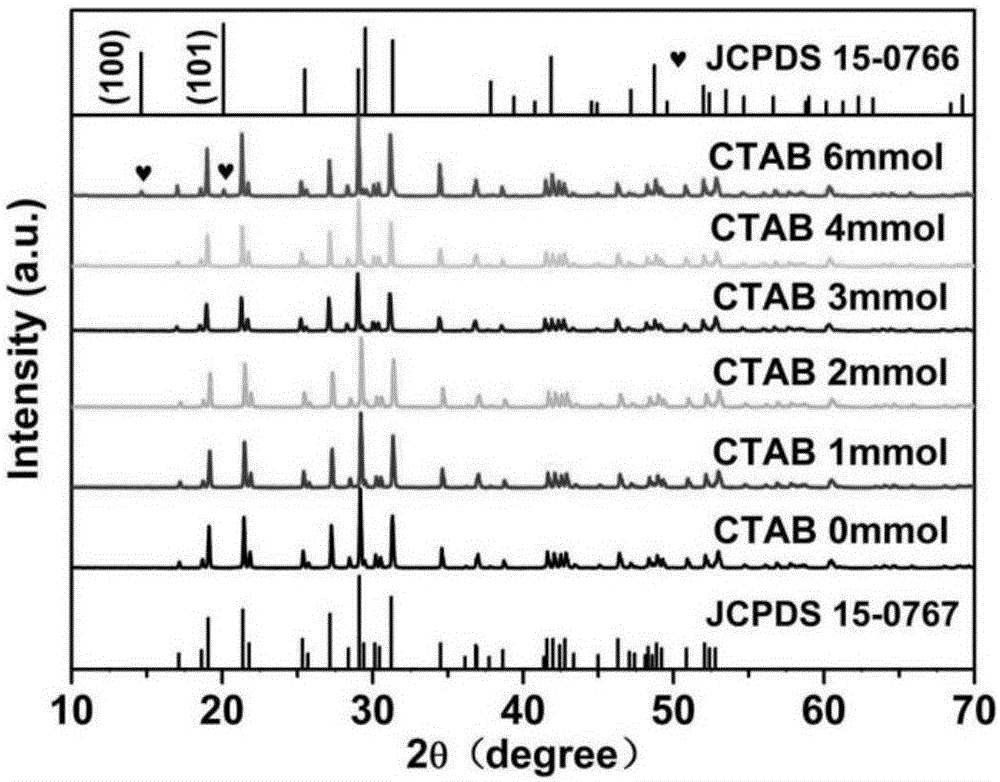

[0051] figure 1 It is the auxiliary synthesis of Bi with different CTAB additions 0.95 PO 4 :0.05Eu 3+ XRD pattern of phosphor powder. It can be seen from the figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com