Natural gas and gasoline double-fuel engine lubricating oil composition

A kind of technology of dual fuel engine, lubricating oil composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

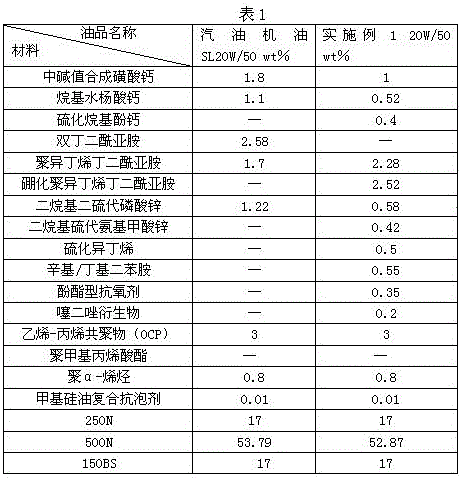

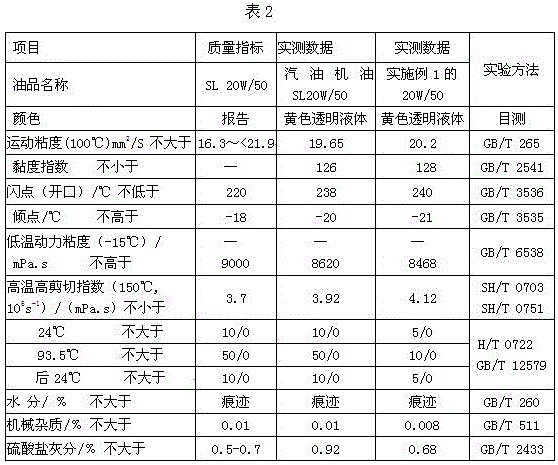

[0031] Example 1 A natural gas and gasoline dual-fuel engine lubricating oil composition 20W / 50 (abbreviated as 20W / 50), consisting of the following raw materials in mass percentage: detergent: 1.0% synthetic calcium sulfonate with medium alkali value, alkyl salicyl Calcium acid 0.52%, sulfurized alkyl phenate calcium 0.4%; dispersant: polyisobutylene succinimide 2.28%, boronated polyisobutylene succinimide 2.52%; antiwear agent: zinc dialkyl dithiophosphate 0.58%, zinc dialkylthiocarbamate 0.42% and sulfurized isobutylene 0.5%; antioxidants: octyl / butyl diphenylamine 0.55%, phenolic ester type antioxidant 0.35%, thiadiazole derivatives 0.2%; Viscosity index improver: ethylene-propylene copolymer (OCP) 3%; pour point depressant: polyalphaolefin 0.8%; antifoaming agent: methyl silicone oil composite antifoaming agent 0.01%; base oil 250N 17% ﹑ 500N 52.87% and 150BS 17%.

[0032] The preparation method of 20W / 50 in Example 1 is as follows: According to the proportion, add base ...

Embodiment 2

[0053] Example 2 The composition of a natural gas and gasoline dual-fuel engine lubricating oil composition 10W / 40 (referred to as 10W / 40), the viscosity index improver mentioned in the composition: ethylene-propylene copolymer (OCP) is 6%; Base oil 250N is 27%, 500N is 8% and 150N is 48.87%, the rest is the same as 20W / 50;

[0054] The preparation method of 10W / 40 in Example 2 is as follows: according to the proportion, add the base oil into the reactor, heat up to 60°C-70°C, then add other materials, stir for 90-150 minutes, filter, test, and fill.

[0055] See Table 5 for the composition comparison between 10W / 40 in Example 2 and the existing gasoline engine oil SL10W / 40 gasoline engine oil.

[0056]

[0057] The technical parameters of 10W / 40 of embodiment 2 and existing gasoline engine oil SL 10W / 40 are listed in table 6. Implement the standard GB11121-2006.

[0058]

[0059] The data in Table 5 and Table 6 show that the difference between gasoline engine oil SL 1...

Embodiment 3

[0068] Example 3 Composition of a natural gas and gasoline dual-fuel engine lubricating oil composition 5W / 30 (abbreviated as 5W / 30): the viscosity index improver: ethylene-propylene copolymer (OCP) 2%, polymethacrylic acid Ester (PMA) 2%; base oil 100N 30.87% and 150N 55%, and the rest are the same as in Example 1.

[0069] The preparation method of 5W / 30 is as follows: According to the proportion, add the base oil into the reaction kettle, raise the temperature to 60°C-70°C, then add other materials, stir for 90-150 minutes, filter, test, and fill.

[0070] The composition comparison between 5W / 30 of Example 3 and the existing gasoline engine oil SL 5W / 30 is shown in Table 8.

[0071]

[0072] The technical parameters of the 5W / 30 of Example 3 and the existing gasoline engine oil SL 5W / 30 are listed in Table 9. Implement the standard GB 11121-2006.

[0073]

[0074] The data in Table 8 and Table 9 show that the difference between gasoline engine oil SL 5W / 30 and 5W / 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum non-jamming load | aaaaa | aaaaa |

| Maximum non-jamming load | aaaaa | aaaaa |

| Load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com