Narrow temperature zone temperature control Ni-Ti shape memory alloy and preparation method and application thereof

A technology of memory alloy and temperature zone, which is applied in the field of narrow temperature zone temperature control Ni-Ti shape memory alloy and its preparation, can solve the problems of time-consuming, environmental pollution, affecting the application of shape memory effect, etc., and achieve the goal of shortening the time spent Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Step (1): Composition design of Ni-Ti shape memory alloy with narrow temperature zone temperature control

[0038] The alloy composition is designed as Ti by mass percentage 44.73 Ni 55.27 , this composition can make the alloy meet the purpose of reducing the driving force of phase change and responding to phase change in a narrow temperature range.

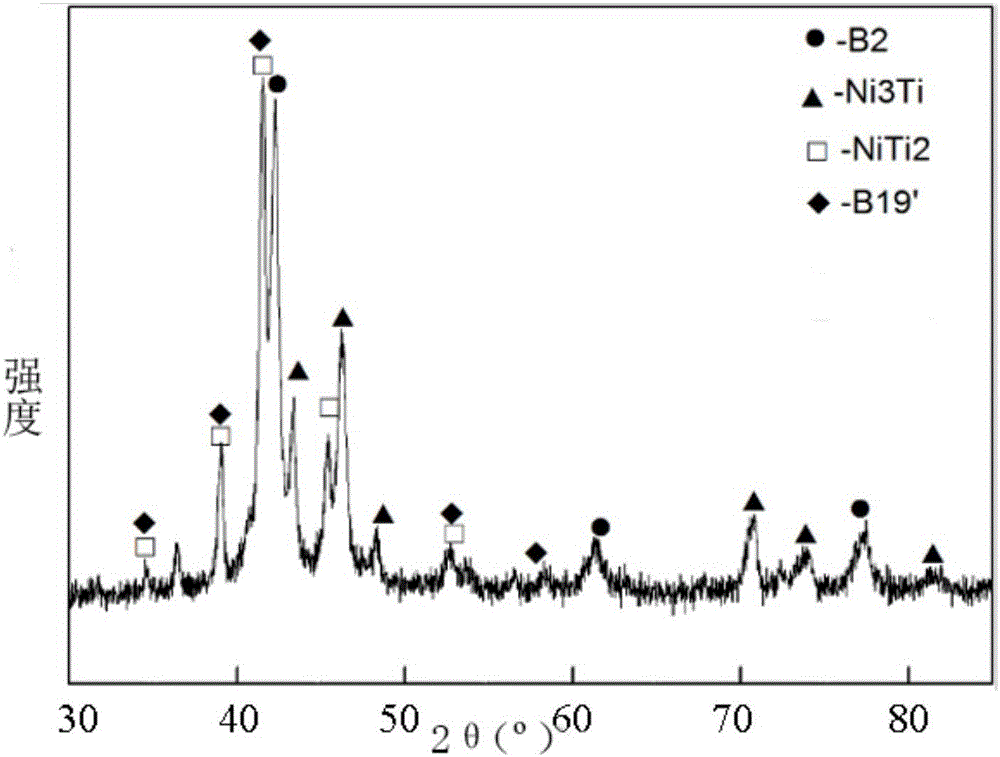

[0039] Step (2): Preparation of Ni-Ti shape memory alloy with narrow temperature zone temperature control

[0040] The uniformly mixed Ni-Ti alloy powder is placed in an argon-protected planetary ball mill (QM-2SP20) for high-energy ball milling. The ball milling media such as the tank and ball materials are all stainless steel, and the diameters of the balls are 15, 10, and 6mm, respectively. , and their weight ratio is 1:3:1. The high-energy ball milling process parameters are as follows: the ball mill tank is filled with high-purity argon (99.999%, 0.5MPa) for protection, the ball-to-material ratio is 7:1, and the sp...

Embodiment 2

[0053] Step (1): Composition design of Ni-Ti shape memory alloy with narrow temperature zone temperature control

[0054] The alloy composition is designed as Ti by mass percentage 44.43 Ni 46.69 Cu 8.88 , Adding a small amount of Cu can make the alloy meet the purpose of reducing the driving force of phase change and responding to phase change in a narrow temperature range.

[0055] Step (2): Preparation of Ni-Ti shape memory alloy with narrow temperature zone temperature control

[0056] Select Ti, Ni and Cu elemental components with purity better than 99.7wt%, according to the mass percentage designed in step (1), adopt the vacuum suction casting method, through six times of repeated smelting, make the components homogeneous, and obtain a diameter of Φ6 ×50mm shape memory alloy rod.

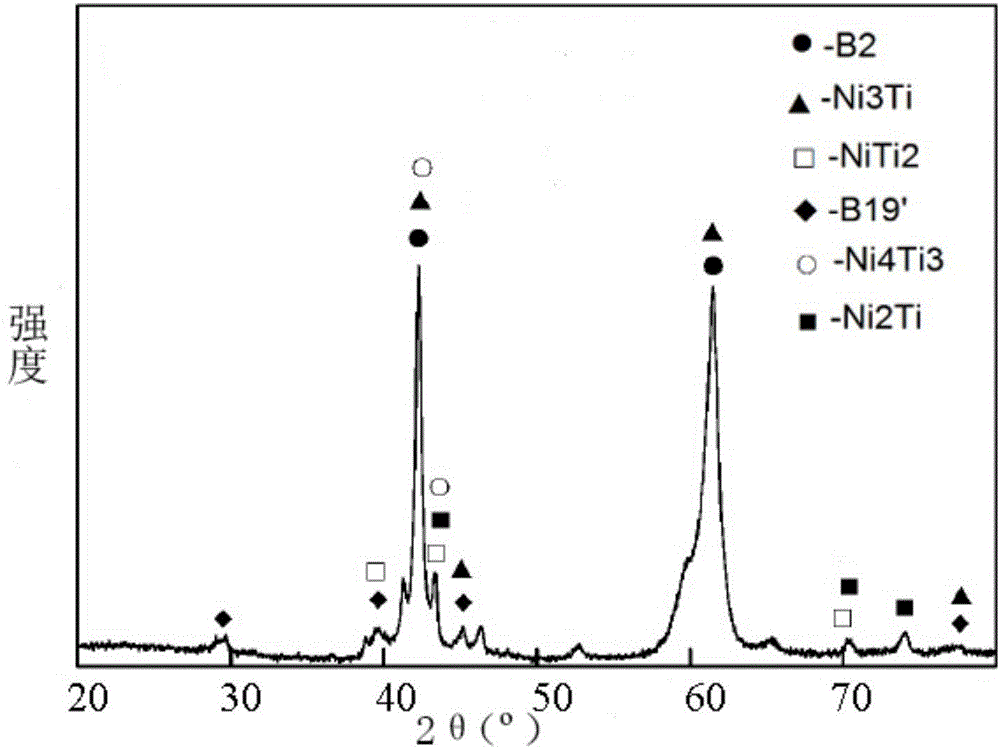

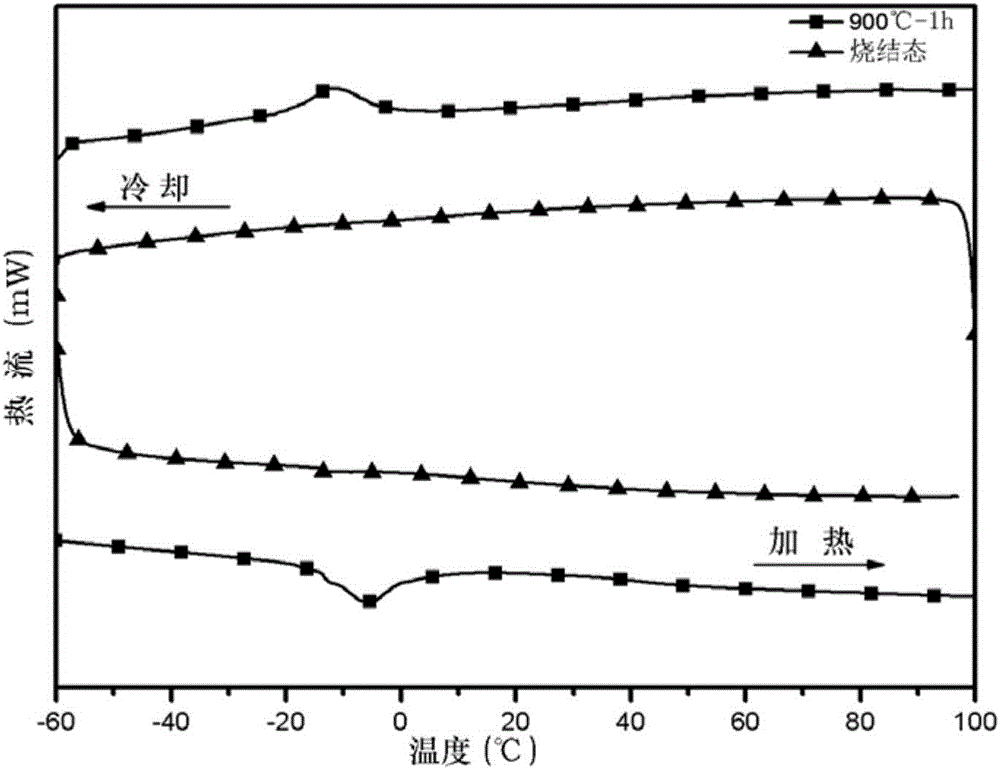

[0057] Step (3): Pulse current heat treatment of Ni-Ti shape memory alloy with narrow temperature zone temperature control

[0058] Cut the shape memory alloy bar stock obtained in step (...

Embodiment 3

[0068] Step (1): Composition design of Ni-Ti shape memory alloy with narrow temperature zone temperature control

[0069] The alloy composition is designed as Ti by mass percentage 51 Ni 49 , this composition can make the alloy meet the purpose of reducing the driving force of phase change and responding to phase change in a narrow temperature range.

[0070] Step (2): Preparation of Ni-Ti shape memory alloy with narrow temperature zone temperature control

[0071] The metal blocks of pure Ni (99.7%) and pure Ti (99.9%) are smelted repeatedly until the composition is uniform, and then suction-cast to obtain a cylindrical shape memory alloy material.

[0072] Step (3): Pulse current heat treatment of Ni-Ti shape memory alloy with narrow temperature zone temperature control

[0073] Cut the bulk shape memory alloy sample obtained in step (2) into small cylinders of Φ6×12mm and put them into the mold, and perform low-temperature short-time annealing heat treatment by pulse cur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com