A kind of colorless transparent polyimide film aluminized thermal control coating and preparation method thereof

A technology of transparent polyimide and thermal control coating, which is applied in coating, metal material coating process, sputtering plating, etc., can solve the problems of good heat dissipation performance, low theoretical equilibrium temperature, and low absorption-radiation ratio , to achieve good heat dissipation and heat preservation performance, moderate theoretical equilibrium temperature, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

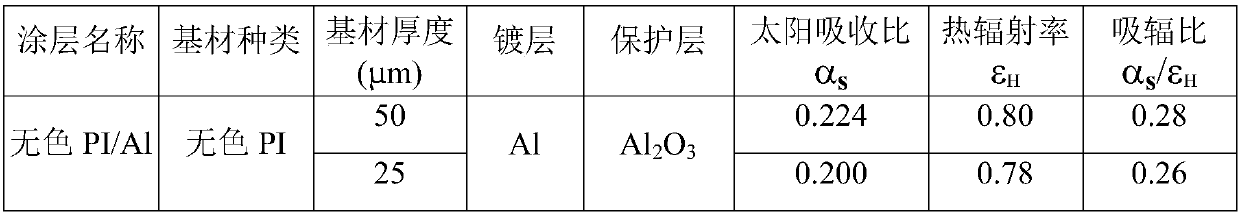

[0021] The structure and preparation process of a colorless PI / Al flexible thermal control composite coating material will be further described below with reference to the description of the drawings and specific embodiments.

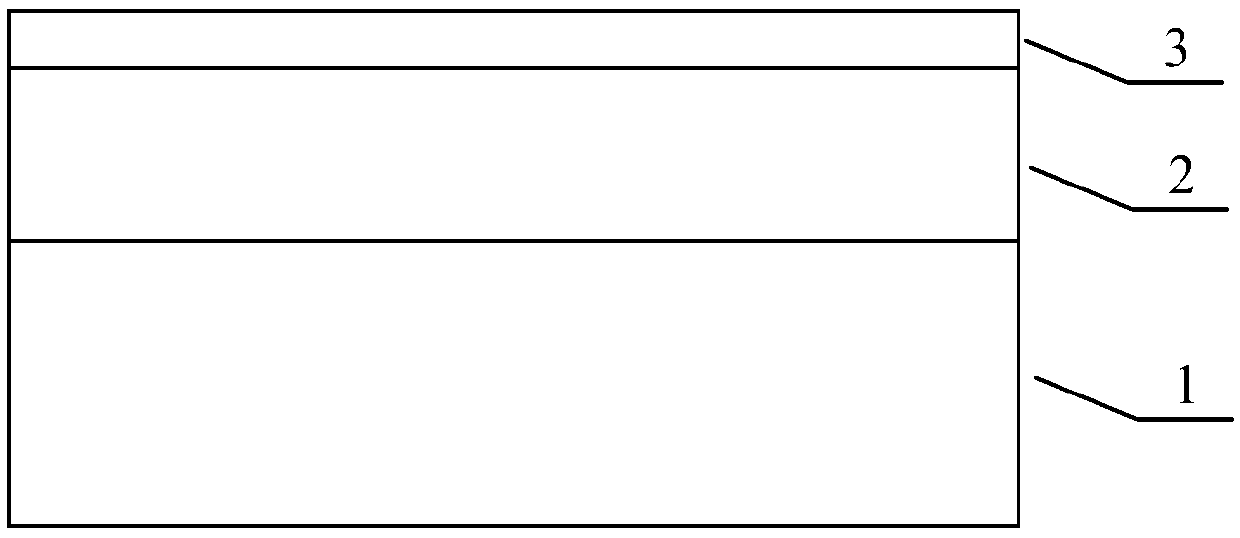

[0022] in: figure 1 It is a schematic structural diagram of a colorless PI / Al flexible thermal control composite coating material. The reason why the colorless PI film is selected as the substrate 1 is that the thermal emissivity of the PI film is relatively large. Compared with golden yellow PI, colorless PI has higher transmittance and lower absorption. The reason for choosing aluminum as the reflective layer 2 is that the reflectivity of aluminum in the whole band is high. When encountering dry air, the aluminum surface can be self-passivated to form a dense aluminum oxide layer as the protective layer 3 to protect the aluminum in the inner layer from oxidation.

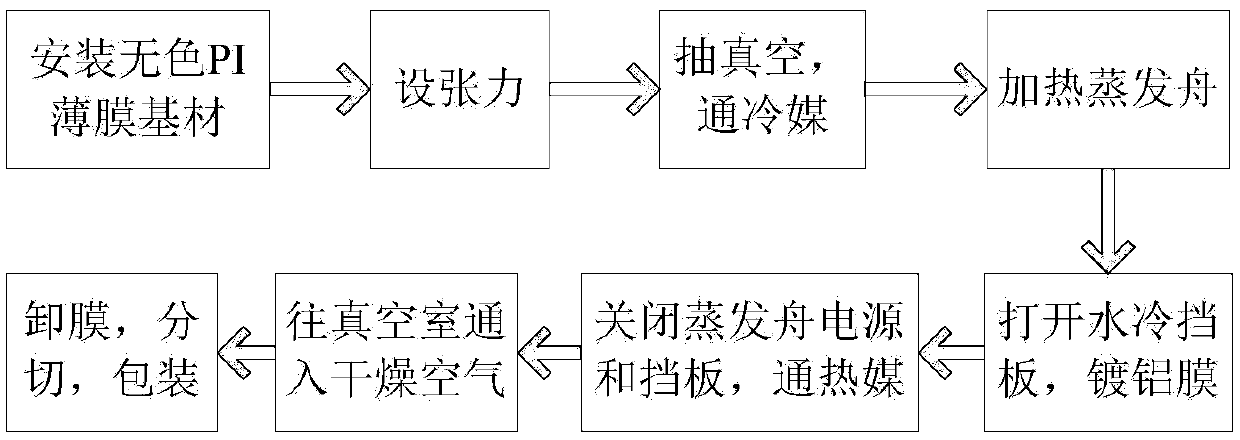

[0023] The preparation process of the colorless PI / Al flexible thermal control compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com