Crucible furnace for preparing low-carbon low-oxygen silicon ingot

A technology of crucible furnace and oxygen silicon, which is applied in the field of crucible furnace for preparing low-carbon and low-oxygen silicon ingots, can solve the problems of high carbon and oxygen content in silicon ingots, reduce the carbon content and oxygen content of products, and achieve quality improvement, Not easy to soften and deform, the effect of reducing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

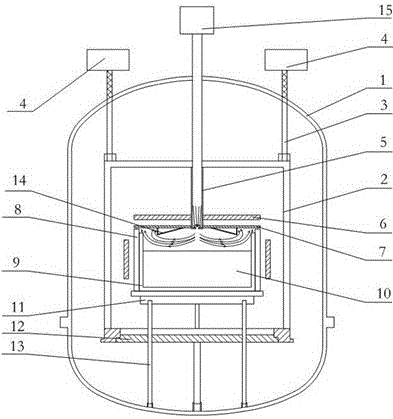

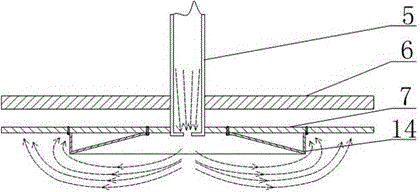

[0020] Such as Figure 1 to 2 As shown, a crucible furnace for preparing low-carbon and low-oxygen silicon ingots of the present invention includes a furnace body 1, an insulation cage 2 is installed in the furnace body 1, and a lifting device 4 is connected to the insulation cage 2, and the lifting device 4 passes The lifting screw 3 is used to realize the lifting of the heat insulation cage 2. The bottom of the heat insulation cage 2 is the heat insulation bottom plate 12, and the directional solidification base 11 is installed in the heat insulation cage 2, and the bottom of the directional solidification base 11 passes through the heat insulation bottom plate 12 Supported by the pillar 13 of the directional solidification base 11, a quartz crucible 9 is installed. The inside of the quartz crucible 9 is filled with silicon melt 10. A graphite guard 8 is installed around the quartz crucible 9. The height of the graphite guard 8 is greater than The height of the quartz crucibl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com