Silkworm silk fibroin nanofiber and preparation method thereof

A silk fibroin and nanofiber technology, applied in spinning solution preparation, single-component silk fibroin man-made filament, fiber processing, etc. and other problems, to achieve the effect of reducing production cost, increasing length, and shortening the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

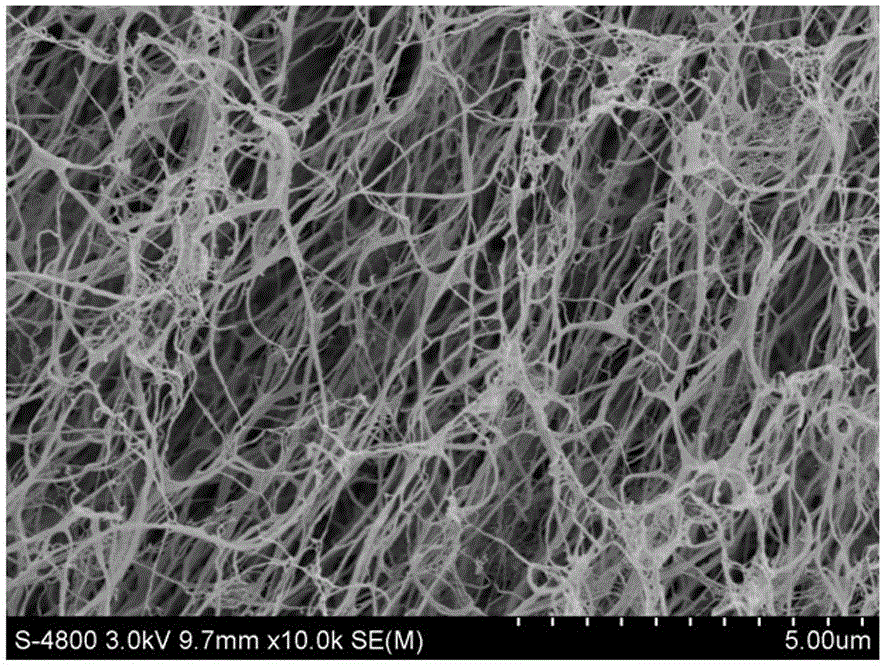

Image

Examples

Embodiment 1

[0022] This embodiment provides a method for preparing silk fibroin nanofibers, the specific steps are as follows:

[0023] (1) Dissolve and dialyze the degummed and dried pure silk fibroin fibers with 9.3M lithium bromide to obtain a fresh silkworm silk fibroin solution, which is poured into a polystyrene mold with a thickness of 1 mm. Rapid drying and molding under % humidity environment.

[0024] (2) Soak the silk fibroin film formed after rapid drying in ethanol for 30 minutes at room temperature to obtain a recrystallized silk fibroin film.

[0025] (3) Soak the recrystallized silk fibroin film at a ratio of 1 / 30 (w / v) in tris-hydrochloric acid buffer solution at 37°C, 0.001M, pH=7.0 for 0.5h, and then Centrifuge at 5000 rpm for 14 min to separate the supernatant.

[0026] (4) After diluting the supernatant obtained above to 0.5 mg / ml, culture in a constant temperature water bath environment for 3 hours to obtain silk fibroin nanofiber aggregates in a wet state.

[002...

Embodiment 2

[0030] (1) Dissolve and dialyze the degummed and dried pure silk fibroin fibers with 9.3M lithium bromide to obtain a fresh silkworm silk fibroin solution, which is poured into a polystyrene mold with a thickness of 3 mm, at 25°C, 60 Rapid drying and molding under % humidity environment.

[0031] (2) Soak the silk fibroin film formed after rapid drying in ethanol for 60 minutes at room temperature to obtain a recrystallized silk fibroin film.

[0032] (3) Soak the recrystallized silk fibroin film at a ratio of 1 / 50 (w / v) in 37°C, 0.01M, pH=7.0 sodium hydrogen phosphate-sodium dihydrogen phosphate buffer solution, soaking time is 1 h, then centrifuged at 3000 rpm for 17 min, and separated to obtain the supernatant.

[0033] (4) After diluting the supernatant obtained above to 0.25 mg / ml, culture in a constant temperature water bath environment for 6 hours to obtain silk fibroin nanofiber aggregates in a wet state.

[0034] (5) Freeze-drying the above aggregates of wet silk fi...

Embodiment 3

[0036] (1) Dissolve and dialyze the degummed and dried pure silk fibroin fibers with 9.3M lithium bromide to obtain a fresh silkworm silk fibroin solution, which is poured into a polystyrene mold with a thickness of 2 mm. Rapid drying and molding under % humidity environment.

[0037] (2) Soak the silk fibroin film formed after rapid drying in ethanol for 120 minutes at room temperature to obtain a recrystallized silk fibroin film.

[0038] (3) Soak the recrystallized silk fibroin film at a ratio of 1 / 30 (w / v) in tris-hydrochloric acid buffer solution at 37°C, 0.05M, pH=7.0 for 0.5h, then 7000 Centrifuge at rpm for 10 min and separate to obtain the supernatant.

[0039] (4) After diluting the supernatant obtained above to 0.75 mg / ml, culture in a constant temperature water bath environment for 3 hours to obtain silk fibroin nanofiber aggregates in a wet state.

[0040] (5) Freeze-drying the above aggregates of wet silk fibroin nanofibers to obtain dry silk fibroin nanofibers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com