A kind of collagen cellulose fiber and preparation method thereof

A technology of cellulose fiber and collagen, which is applied in the direction of cellulose/protein conjugated artificial filament, fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of high broken filament rate of collagen fiber and not being economical enough, and achieve Good softness, wrinkle reduction, high moisturizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

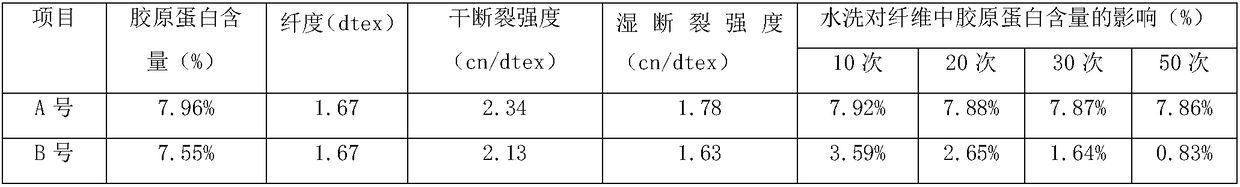

Image

Examples

Embodiment 1

[0028] Carry out the following steps:

[0029] (1) Preparation of collagen pretreatment solution: pump 50L of water into the glass-lined reactor, start stirring, and add 10Kg of collagen, then add dilute sodium hydroxide solution to adjust the pH of the system to 9-10 to fully dissolve the collagen Protein and filtered to obtain an alkaline aqueous solution, then heat the collagen aqueous solution to 55-65°C, maintain the system temperature at 55-65°C, add 3.5L epichlorohydrin dropwise to the system within 20-30min under stirring conditions, and dropwise add Then raise the system temperature to 100-110°C, maintain the system temperature at 100-110°C and react for 2 hours to obtain the collagen pretreatment solution, then lower it to room temperature for later use;

[0030] (2) Viscose grafting treatment: Before the viscose enters the aging intermediate barrel, add the collagen pretreatment solution prepared in step (1) with the injection system according to the ratio of collag...

Embodiment 2

[0035] Carry out the following steps:

[0036] (1) Preparation of collagen pretreatment solution: pump 50L of water into the glass-lined reactor, start stirring, and add 10Kg of collagen, then add dilute sodium hydroxide solution to adjust the pH of the system to 9-10 to fully dissolve the collagen Protein and filtered to obtain an alkaline aqueous solution, then heat the collagen aqueous solution to 55-65°C, maintain the system temperature at 55-65°C, add 3.5L epichlorohydrin dropwise to the system within 20-30min under stirring conditions, and dropwise add Finally, raise the system temperature to 100-110°C, maintain the system temperature at 100-110°C and react for 3 hours to obtain the collagen pretreatment solution, and then lower it to room temperature for later use;

[0037] (2) Viscose grafting treatment: Before the viscose enters the aging intermediate barrel, add the collagen pretreatment solution prepared in step (1) with the injection system according to the ratio o...

Embodiment 3

[0040] Carry out the following steps:

[0041](1) Preparation of collagen pretreatment solution: pump 50L of water into the glass-lined reactor, start stirring, and add 10Kg of collagen, then add dilute sodium hydroxide solution to adjust the pH of the system to 9-10 to fully dissolve the collagen Protein and filtered to obtain an alkaline aqueous solution, then heat the collagen aqueous solution to 55-65°C, maintain the system temperature at 55-65°C, add 3.5L epichlorohydrin dropwise to the system within 20-30min under stirring conditions, and dropwise add Finally, raise the system temperature to 100-110°C, maintain the system temperature at 100-110°C and react for 3 hours to obtain the collagen pretreatment solution, and then lower it to room temperature for later use;

[0042] (2) Viscose grafting treatment: Before the viscose enters the aging intermediate barrel, add the collagen pretreatment solution prepared in step (1) with the injection system according to the ratio of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com