Coal pyrolysis reaction thermal testing method based on heat flow type DSC technique

A technology of coal pyrolysis and reaction heat, which is applied in the direction of material heat development, can solve the problems of inconvenient and reliable measurement of coal pyrolysis reaction heat, etc., and achieve the effect of continuous measurement process and simple calculation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

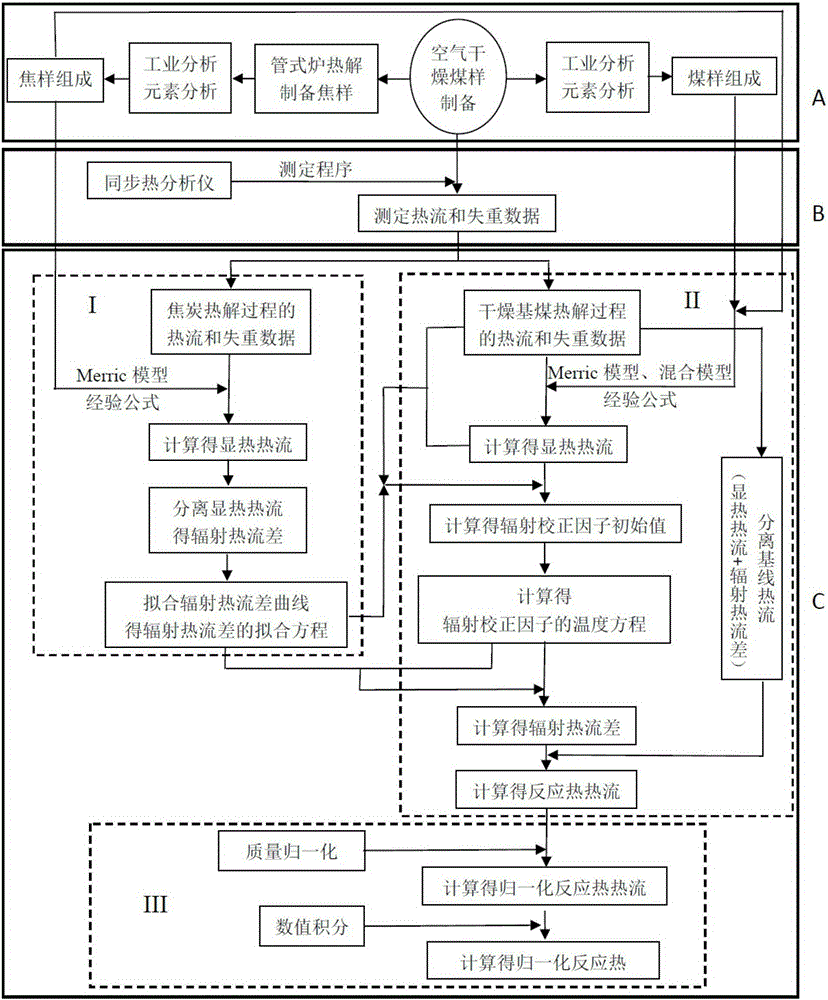

[0032] (A) Preparation and analysis of air-dried coal and coke samples

[0033] According to the present invention, the coal is air-dried, implemented according to GB474-2008; the pyrolysis conditions include: the nitrogen flow rate is 100mL / min, the heating rate is 5°C / min, the final pyrolysis temperature is 1100°C, and the constant temperature time is 60 min; the air-dried coal sample and the coke sample were subjected to the industrial analysis according to GB / T212-2008, and the elemental analysis according to GB / T476-2001.

[0034] Specifically, the following steps may be included:

[0035] i) Take a fresh coal sample and crush it until the particle diameter is less than 0.074mm, and air-dry the coal sample according to the provisions of GB474-2008 to prepare an air-dried coal sample with a particle diameter of less than 0.074mm;

[0036] ii) Put 5g of air-dried coal sample into an open quartz boat and place it in a tube furnace for pyrolysis. Before pyrolysis, the furn...

Embodiment 1

[0137] This example illustrates the method for measuring the reaction heat of coal pyrolysis under open crucible conditions based on the heat flow DSC technology of the present invention.

[0138] (1) Sample preparation and analysis: Take the Inner Mongolia Shengli lignite sample, crush it to a particle size of less than 0.074mm, and then perform air drying according to the provisions of GB474-2008 to make an air-dried coal sample with a particle size of less than 0.074mm; take 5g of air The dried coal sample was placed in an open quartz boat and then placed in a tube furnace for pyrolysis. During pyrolysis, the flow rate of carrier gas (high-purity nitrogen gas) was 100 mL / min, the heating rate was 5 °C / min, and the final pyrolysis temperature was 1100°C, the constant temperature time is 60 minutes, and the furnace tube is purged with carrier gas for 30 minutes before pyrolysis to remove residual oxygen; according to the provisions of GB / T212-2008 and GB / T476-2001, air-dried c...

Embodiment 2

[0158] This example illustrates the method for measuring the reaction heat of coal pyrolysis under open crucible conditions based on the heat flow DSC technology of the present invention.

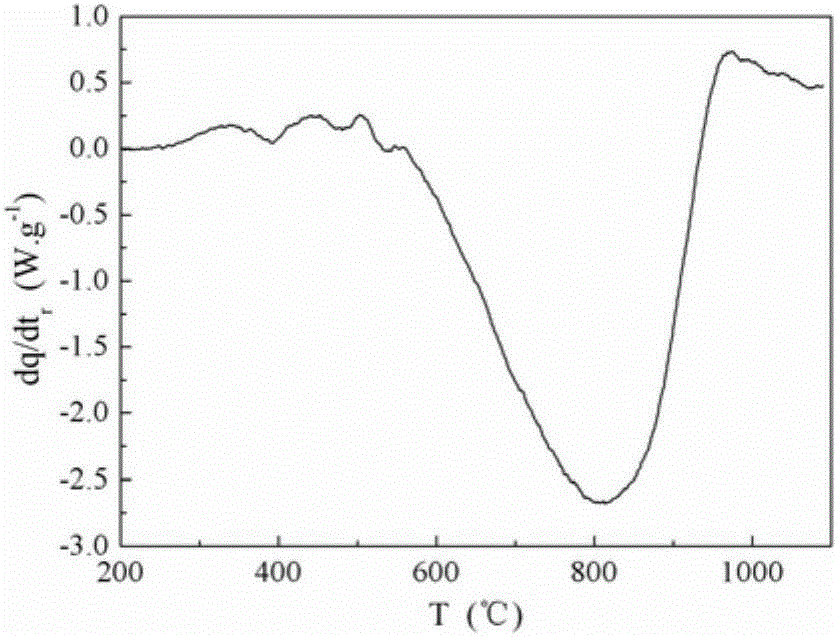

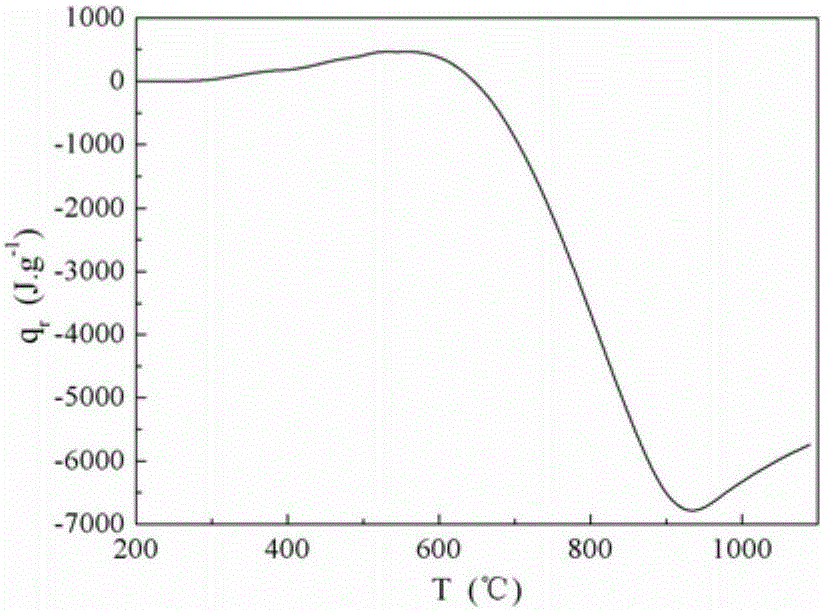

[0159] Take the Shaanxi Shenmu bituminous coal sample, carry out sample preparation and analysis according to the method in Example 1, measure heat flow and weight loss data, and calculate the normalized reaction heat flow and normalized reaction heat of coal.

[0160] The basic parameters required for the calculation process (including some industrial analysis and elemental analysis data of air-dried coal samples and coke samples, as well as related quality data) are shown in Table 3. See Table 4 for the combined equation and the temperature equation of the radiation correction factor λ in different temperature ranges. The normalized reaction heat flow curve and normalized reaction heat curve of Shenmu bituminous coal are shown in Figure 4 , Figure 5 shown.

[0161] table 3

[0162] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com