Device and method for testing slit/sludge dehydration rate in multi-physics field condition

A multi-physics field and sludge dewatering technology, applied in the fields of geotechnical engineering, environmental science and engineering, can solve the problems of high energy consumption, lack of theoretical and experimental data support, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

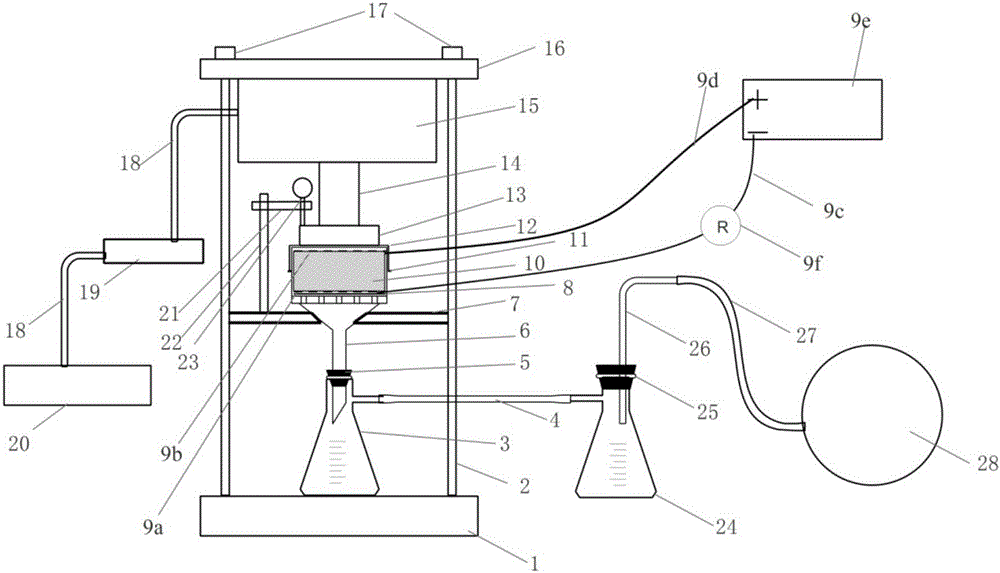

[0029] like figure 1 As shown, a device for testing the dehydration rate of silt / sludge under multi-physics field conditions includes the first upper mouth suction filter bottle 3, and also includes a ceramic Buchner funnel 6, the cylinder of the ceramic Buchner funnel 6 rests on the bracket 7, the long-necked end of the ceramic Buchner funnel 6 passes through the bracket 7 and the first rubber stopper 5 arranged on the mouth of the first upper mouth suction filter bottle 3 and extends into the first upper mouth suction filter bottle 3, A silt / sludge sample 10 is arranged in the barrel of the ceramic Buchner funnel 6, and the top and bottom layers of the silt / sludge sample 10 are respectively provided with an upper electrode plate with holes 9b and a lower electrode plate with holes 9a, and the lower electrode plate with holes 9a Located on the filter paper 8, the cylinder mouth of the ceramic Buchner funnel 6 is wrapped by a rubber film 12, and the rubber film 12 is provided ...

Embodiment 2

[0035] Use the device of testing silt / sludge dewatering rate under multi-physics field conditions described in embodiment 1 to carry out a kind of test method of silt / sludge soil dewatering rate under multi-physics coupling, comprising the following steps:

[0036] Step 1. Turn on the vacuum pump 28 and set the negative pressure value of the vacuum pump 28. The negative pressure value can be -10kPa or -20kPa or -30kPa or -40kPa or -50kPa or -60kPa or -70kPa or -80kPa or -90kPa;

[0037] Step 2. Turn on the air compressor 20, and control the pressure of the piston 14 through the air pressure controller 19, so that the piston 14 extends out of the piston cylinder 15 and closely contacts the pressure transmission plate 13, so that the overlying pressure of the silt / sludge sample 10 reaches the set value Pressure value, the pressure value can be 10KPa or 20kPa or 30kPa or 40kPa or 50kPa or 100kPa or 200kPa or 300kPa or 400kPa;

[0038] Step 3: Turn on the rectifier transformer 9e ...

Embodiment 3

[0043] In Example 2, step 1, step 2 and step 3 are carried out at the same time, and the dehydration rate under the coupling action of static force field-vacuum pressure field-electric field can be obtained through step 4, step 5 and step 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com