Device and method for testing compressibility of gelled crude oil based on full-seal method

A test device and a fully sealed technology, applied in the direction of material inspection products, etc., can solve the problems of pressure attenuation, piston pressure is not easy to transmit, and the compression chamber is too long, so as to reduce the pressure attenuation, improve the test accuracy, and improve the measurement accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

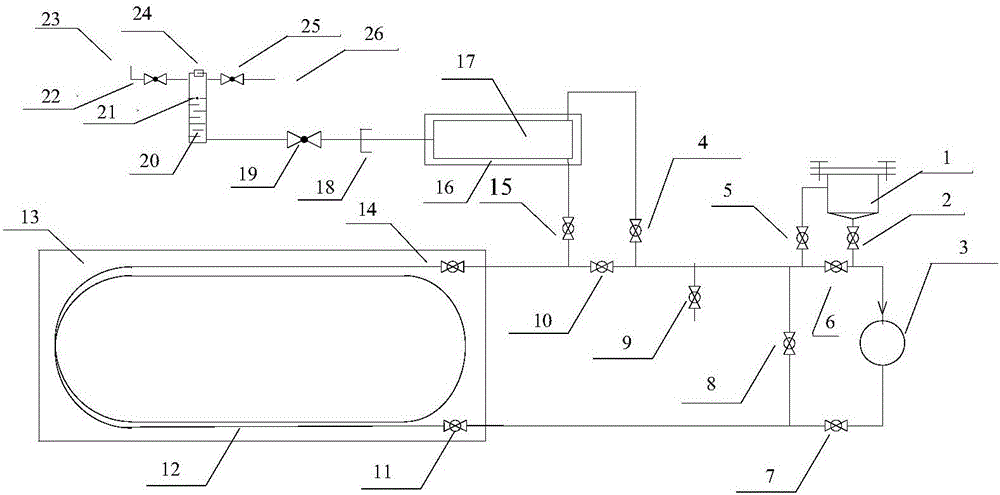

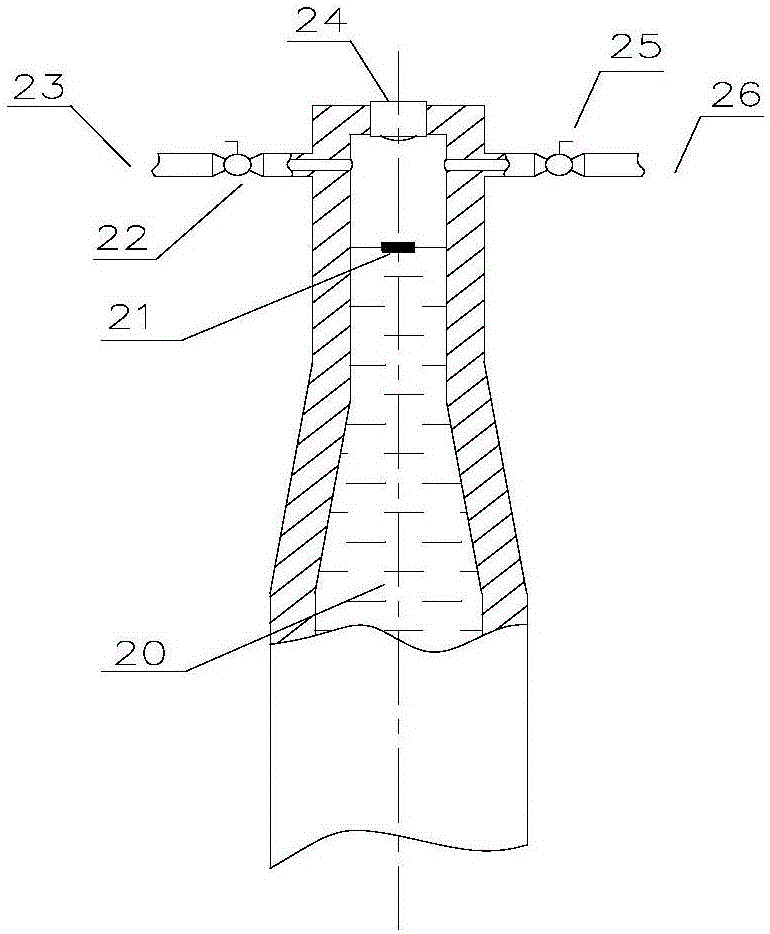

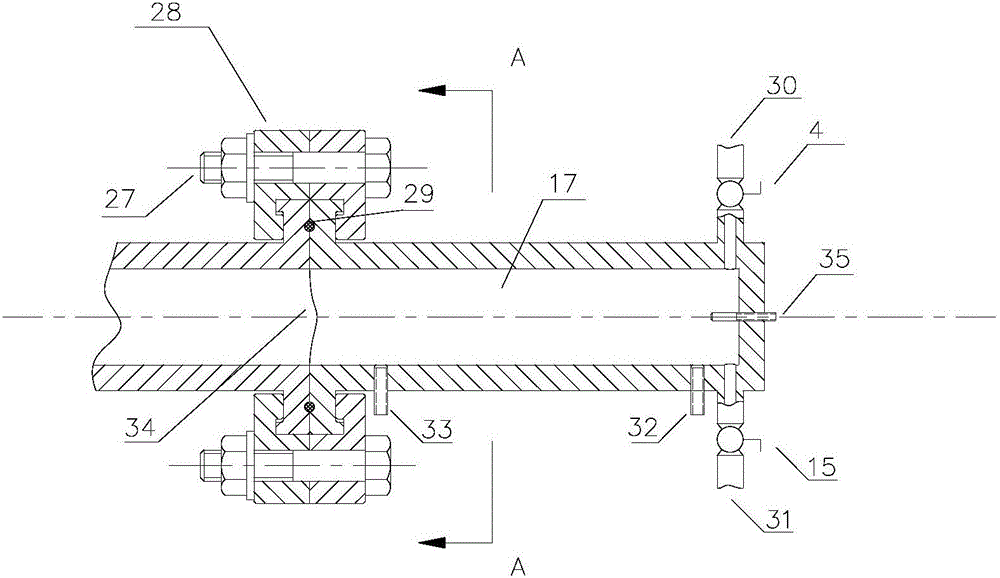

[0038]The base oil is injected into the compression system of this design, so that the elastic film is in a certain position in the connecting pipe, and the crude oil reaches the test temperature after experiencing thermal history and shear history in the annular pipeline; the crude oil treated in the annular pipeline is replaced into the crude oil compression In the tank, the oil sample is left to stand at a specified cooling rate until a gelled structure is formed, and then the crude oil is subjected to a compression test through the base oil and the elastic film. The pressure signal and temperature signal in the crude oil compression system are transmitted to the signal processing system, and the displacement signal is passed through The laser measurement system in the base oil compression system is passed to the signal processing system, which is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com