Multi-system joint optimization dispatching method and device

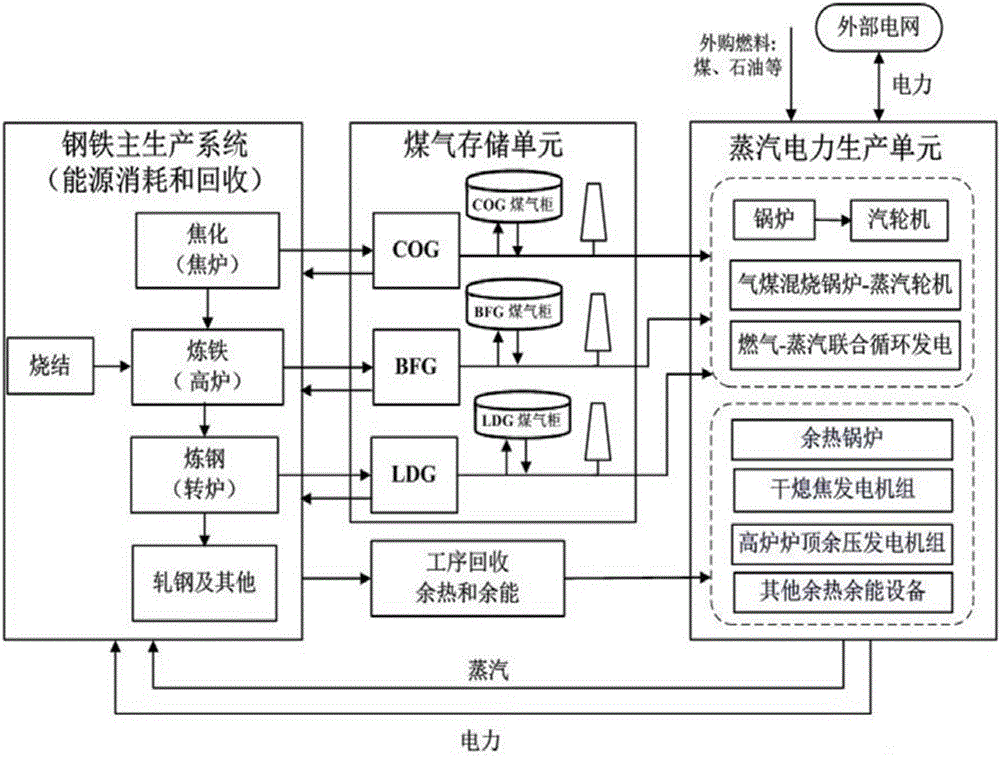

A joint optimization and multi-system technology, applied in general control systems, control/regulation systems, instruments, etc., can solve problems such as energy waste, single energy medium subsystem, and ignore different energy coupling relationships, so as to reduce energy consumption and energy consumption. cost, improving business economics, and improving accuracy and representativeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0031] This embodiment provides a technical solution of a multi-system joint optimal scheduling method.

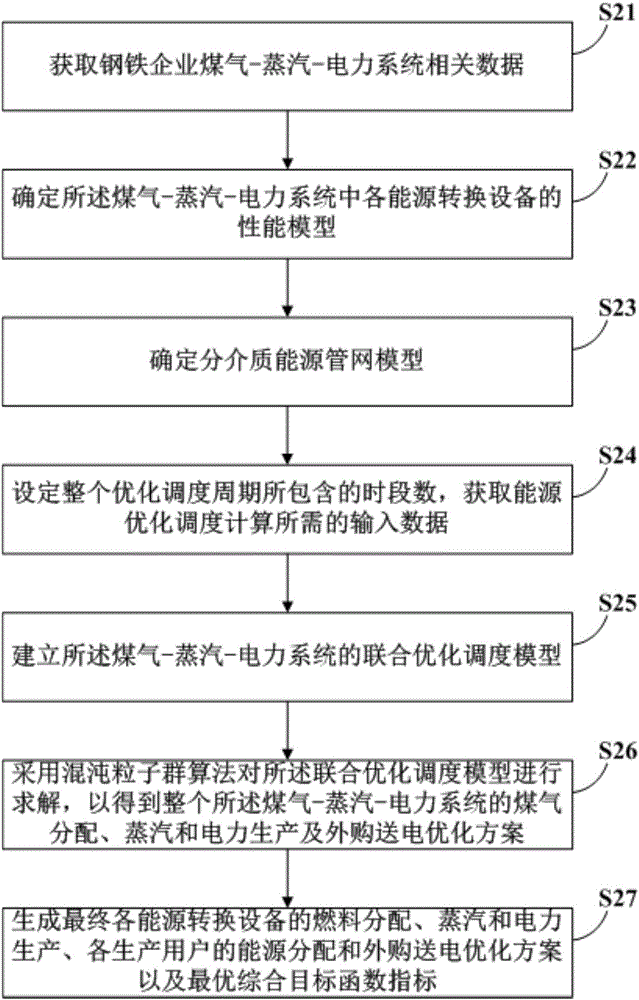

[0032] see figure 2 , the multi-system joint optimal scheduling method includes:

[0033] S21. Obtain data related to the gas-steam-electricity system of the iron and steel enterprise, including the network topology of the energy system and the characteristic parameters of each energy conversion device in the system. The characteristic parameters of each energy conversion equipment include parameters such as the maximum load value, the minimum load value, the maximum load increase speed, the maximum load decrease speed, the normal operating range of the equipment, the upper limit of the gas blending ratio, the lower limit of the mixed gas calorific value, and the initial operation of the equipment. state.

[0034] S22, determining the performance model of each energy conversion equipment in the gas-steam-electricity system of the iron and steel enterprise.

[0035] S23...

no. 2 example

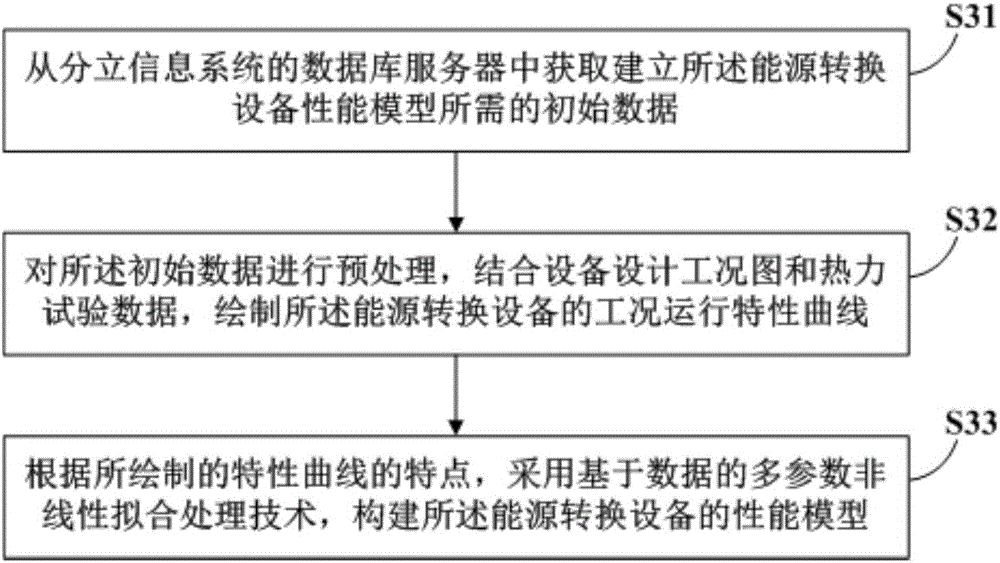

[0102]Based on the foregoing embodiments of the present invention, this embodiment further provides a technical solution for determining a performance model in a multi-system joint optimal scheduling method. In this technical solution, determining the performance model of each energy conversion equipment in the gas-steam-electricity system includes: obtaining the initial data required to establish the performance model of the energy conversion equipment from the database server of the discrete information system; Preprocess the initial data, and draw the operating characteristic curve of the energy conversion equipment in combination with the equipment design working condition diagram and thermal test data; according to the characteristics of the drawn characteristic curve, adopt data-based multi-parameter nonlinear fitting processing technology, constructing the performance model of the energy conversion equipment.

[0103] see image 3 , determining the performance model of...

no. 3 example

[0122] Based on the above-mentioned embodiments of the present invention, this embodiment further provides a technical solution for model solving in a multi-system joint optimal scheduling method. In this technical solution, the joint optimization scheduling model is solved by using the chaotic particle swarm algorithm, so as to obtain the optimization scheme of gas distribution, steam and electric power production and outsourced power transmission of the entire gas-steam-electricity system, including: setting Particle swarm size, number of iterations, control parameters and optimized variable range; initialize particle swarm; construct fitness function; calculate the fitness value of each particle in the current swarm, and determine the individual extremum of each particle and the global extremum of the entire particle swarm; Update the control parameters, wherein the control parameters include inertia weight and acceleration factor; update the velocity and position of each pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com