Co-Fe alloy/graphene compound material, as well as preparation method and application thereof

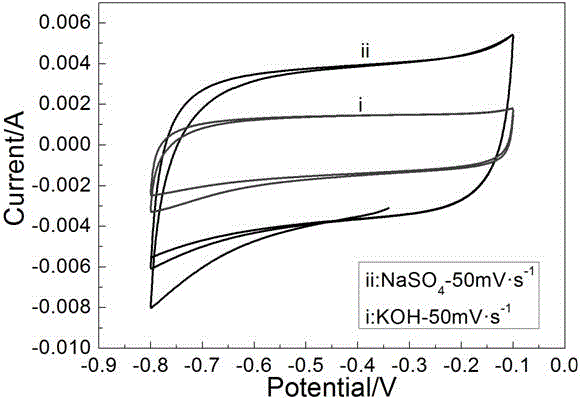

A composite material and graphene technology, applied in the field of electrochemistry, can solve the problems of difficult to obtain uniform composite materials in composite state, easy agglomeration of nanoparticles, etc., and achieve the effect of improving electrochemical performance and broad development prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

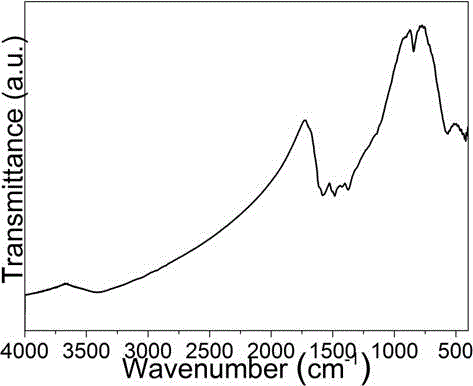

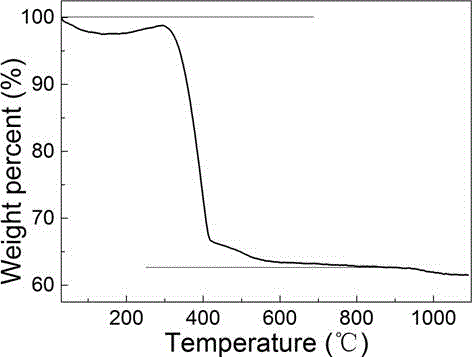

[0025] (1) Graphene oxide was prepared by the improved Hummers method, 300mg graphene oxide was mixed with 400mL deionized water, and the mixture obtained by the two was ultrasonically dispersed for 6 h, and the solution was irradiated with a flashlight beam, and no Obvious particle aggregates indicate that graphene oxide is well dispersed in aqueous solution, thereby obtaining a uniformly dispersed yellow-brown graphene oxide dispersion;

[0026] (2) Dissolve 1g of yellow-brown 1,1'-ferrocenecarboxylic acid powder and 1g of pink cobalt acetate tetrahydrate powder in the graphene oxide dispersion obtained in step (1) at room temperature, stir, Until all the solids are dissolved, the solution turns from yellowish brown to black red;

[0027] (3) Put the yellow-brown solution obtained in step (2) into a constant temperature magnetic stirring water bath, control the constant temperature of the water bath at 70°C, turn on the magnetic stirring, and add sodium hydroxide solution (0...

Embodiment 2

[0039] (1) Prepare graphene oxide by the improved Hummers method, mix 0.2mg graphene oxide with 300mL deionized water, and ultrasonically disperse the resulting mixture for 4 h. Obvious particle aggregates are found, indicating that graphene oxide is well dispersed in aqueous solution, thereby obtaining a uniformly dispersed yellow-brown graphene oxide dispersion;

[0040] (2) Dissolve 1g of yellow-brown 1,1'-ferrocenecarboxylic acid powder and 5g of pink cobalt acetate tetrahydrate powder in the graphene oxide dispersion obtained in step (1) at room temperature, stir, Until all the solids are dissolved, the solution turns from yellowish brown to black red;

[0041] (3) Put the yellow-brown solution obtained in step (2) into a constant temperature magnetic stirring water bath, control the constant temperature of the water bath at 30°C, turn on the magnetic stirring, and add sodium hydroxide solution (0.3M) dropwise during the stirring process to adjust the pH of the solution ...

Embodiment 3

[0045] (1) Prepare graphene oxide by the improved Hummers method, mix 0.7mg graphene oxide with 400mL deionized water, and ultrasonically disperse the resulting mixture for 8 h. Obvious particle aggregates are found, indicating that graphene oxide is well dispersed in aqueous solution, thereby obtaining a uniformly dispersed yellow-brown graphene oxide dispersion;

[0046] (2) Dissolve 1g of yellow-brown 1,1'-ferrocenecarboxylic acid powder and 9g of pink cobalt acetate tetrahydrate powder in the graphene oxide dispersion obtained in step (1) at room temperature, stir, Until all the solids are dissolved, the solution turns from yellowish brown to black red;

[0047] (3) Put the yellow-brown solution obtained in step (2) into a constant temperature magnetic stirring water bath, control the constant temperature of the water bath at 50°C, turn on the magnetic stirring, and add sodium hydroxide solution (0.5M) dropwise during the stirring process to adjust the pH of the solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com