Method for overcoming PETEOS thin film defects and semiconductor structure

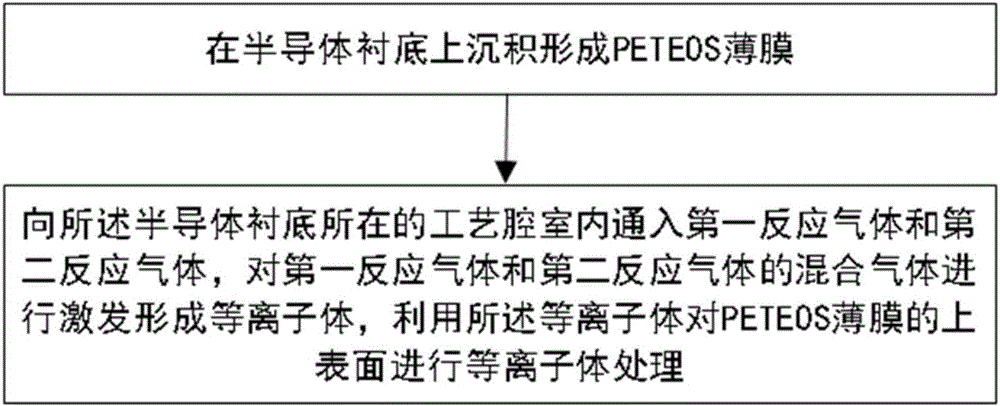

A thin-film defect and semiconductor technology, which is applied in semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve the problems of poor film layer quality and unsatisfactory surface quality of other dielectric films, so as to increase surface activity and reduce Surface hillock defect, effect of reducing hydrogen bond content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In step 2 of this embodiment, a mixed gas of oxygen and helium is introduced into the process chamber where the semiconductor substrate is located, the flow rate of oxygen is 4200 sccm, the flow rate of helium is 4000 sccm, the pressure in the process chamber is 5 torr, and the process The radio frequency power of the radio frequency source in the chamber is 790W, and the temperature in the process chamber is 400°C. After the plasma treatment for 5s, the plasma treatment step of step 2 is completed.

Embodiment 2

[0033] In step 2 of this embodiment, a mixed gas of oxygen and argon is introduced into the process chamber where the semiconductor substrate is located, the flow rate of oxygen is 1000 sccm, the flow rate of argon is 1000 sccm, the pressure in the process chamber is 3 torr, and the process The radio frequency power of the radio frequency source in the chamber is 1000W, the temperature in the process chamber is 500°C, and after plasma treatment for 8s, the plasma treatment step of step 2 is completed.

Embodiment 3

[0035] In step 2 of this embodiment, a mixed gas of oxygen and nitrogen is introduced into the process chamber where the semiconductor substrate is located. The flow rate of oxygen is 6000 sccm, the flow rate of nitrogen gas is 5000 sccm, and the pressure in the process chamber is 10 torr. The radio frequency power of the medium radio frequency source is 600W, and the temperature in the process chamber is 300°C. After plasma treatment for 2s, the plasma treatment step of step 2 is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com