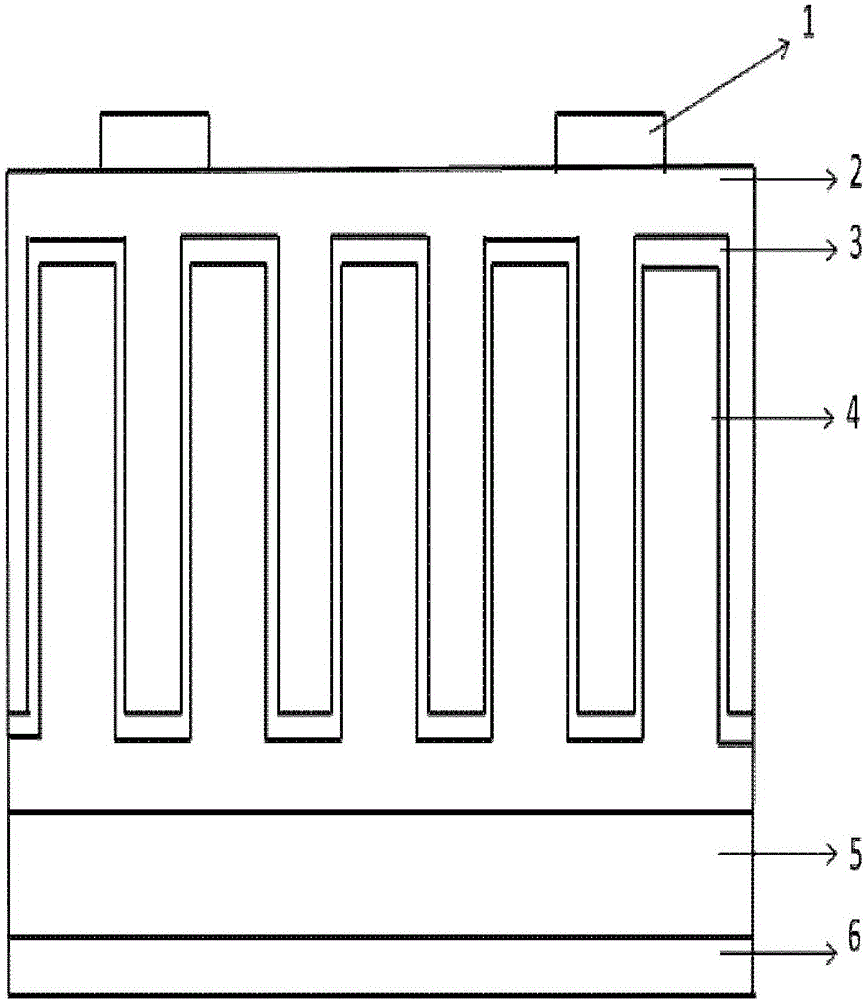

Poly-silicon solar cell

A technology for solar cells and polycrystalline silicon, applied in the field of solar cells, can solve the problem of high cost of preparation methods, and achieve the effects of strong anti-reflection properties, enhanced absorption, and increased current collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The embodiments of the present invention will be described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention. Detailed implementation modes and specific operation procedures are given, but the protection scope of the present invention is not limited to the following implementations. example.

[0013] 1. Clean the p-type polysilicon wafer according to the standard semiconductor cleaning procedure (RCA method), and dry it with nitrogen at room temperature for later use. Under normal temperature and pressure, put the prepared p-type polycrystalline silicon wafer into HF (20%) and AgNO 3 (0.045mol / L) In a Teflon beaker of the etching solution, the reaction is sealed for 60 minutes. Take out the sample with plastic tweezers, and rinse off the residual etching solution with a large amount of deionized water. Then immerse the sample in dilute HNO 3 (20%) solution to remove reduced silver deposits. Finally, clean it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com