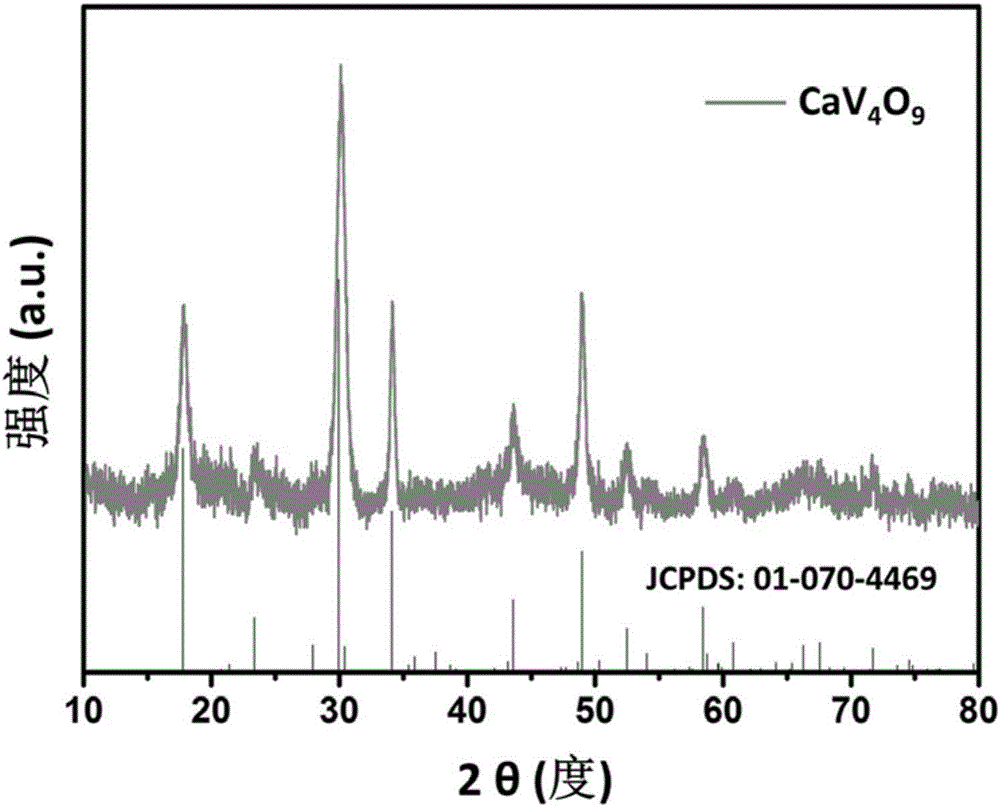

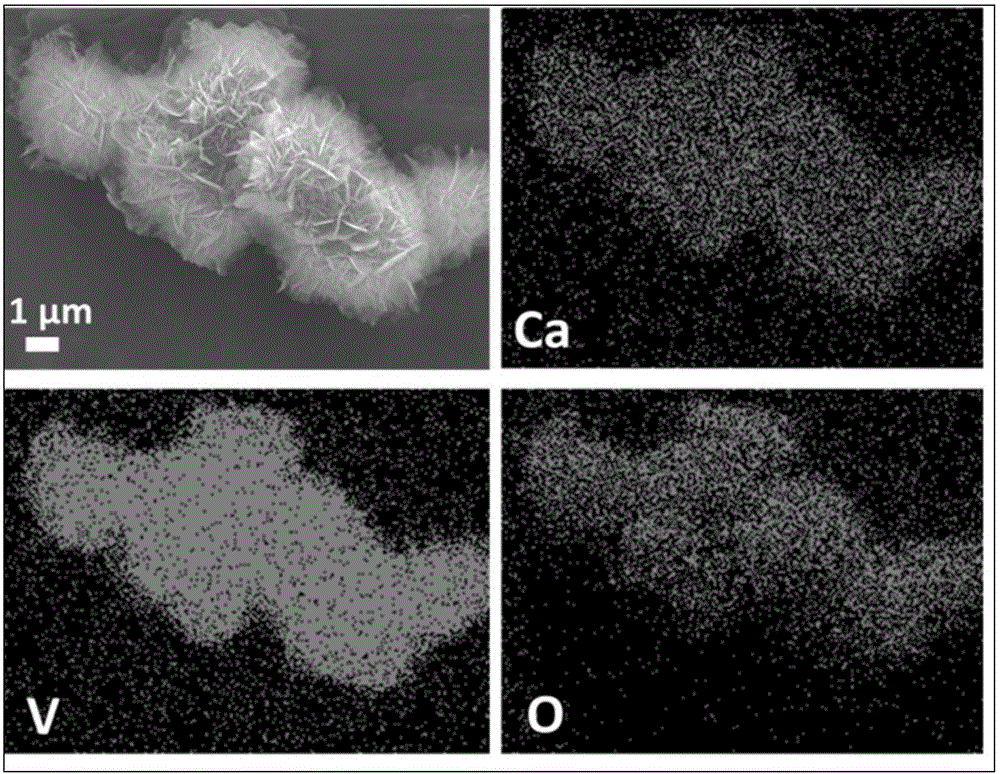

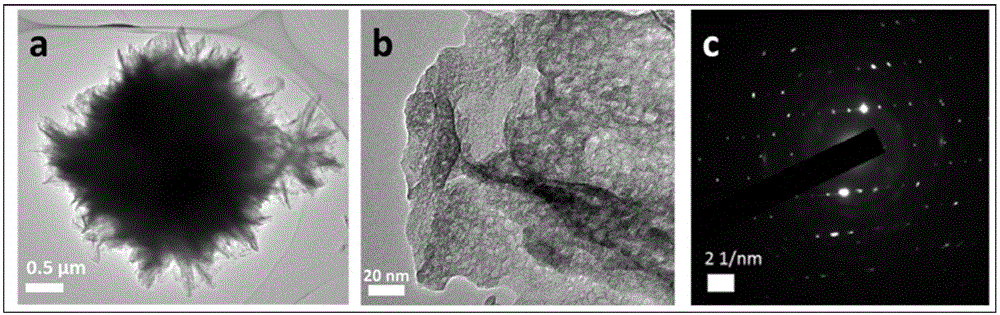

Alkaline metal vanadate electrode material and preparation method and application thereof

A technology of alkaline earth metal and vanadate, applied in the field of nanomaterials and electrochemistry, to achieve excellent rate performance, high tap density and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation of alkaline earth metal vanadate electrode material comprises the following steps:

[0035] 1) Weigh 1.0mmol Ca(OH) 2 (or Sr(OH) 2 ) into 10ml of glycerin, then add 10ml of deionized water, and stir with a magnetic stirrer for 60 minutes;

[0036] 2) Weigh 2.0mmol V 2 o 5 Add to 10ml deionized water, then add 5ml 30% hydrogen peroxide, stir with a magnetic stirrer for 60 minutes;

[0037] 3) Add the solution obtained in step 1) to the solution obtained in step 2), and stir with a magnetic stirrer for 2 hours;

[0038] 4) Transfer the solution obtained in step 3) to a 50ml reaction kettle, heat it in water at 200°C for 2 days, cool it down to room temperature naturally, and take out the black product;

[0039] 5) The product obtained in step 4) is centrifuged, washed with absolute ethanol for 1-2 times, and then dried in an oven at 60-70°C for 12-24 hours;

[0040] 6) heat-treat the dried product obtained in step 5) at 400° C. in an argon atmosphere f...

Embodiment 2

[0050] The preparation of alkaline earth metal vanadate electrode material comprises the following steps:

[0051] 1) Weigh 1.0mmol Ca(OH) 2 (or Sr(OH) 2 ) into 5ml glycerin, then add 15ml deionized water, and stir with a magnetic stirrer for 60 minutes;

[0052] 2) Weigh 2.0mmol V 2 o 5 Add to 10ml deionized water, then add 5ml 30% hydrogen peroxide, stir with a magnetic stirrer for 60 minutes;

[0053] 3) Add the solution obtained in step 1) to the solution obtained in step 2), and stir with a magnetic stirrer for 2 hours;

[0054] 4) Transfer the solution obtained in step 3) to a 50ml reaction kettle, heat it in water at 200°C for 4 days, cool it down to room temperature naturally, and take out the black product;

[0055] 5) The product obtained in step 4) is centrifuged, washed with absolute ethanol for 1-2 times, and then dried in an oven at 60-70°C for 12-24 hours;

[0056] 6) heat-treat the dried product obtained in step 5) at 400° C. in an argon atmosphere for 5 ...

Embodiment 3

[0059] The preparation of alkaline earth metal vanadate electrode material comprises the following steps:

[0060] 1) Weigh 1.2mmol Ca(OH) 2 (or Sr(OH) 2 ) into 10ml of glycerin, then add 10ml of deionized water, and stir for 40 minutes with a magnetic stirrer;

[0061] 2) Weigh 2.0mmol V 2 o 5 Add to 10ml of deionized water, then add 5ml of 30% hydrogen peroxide, stir with a magnetic stirrer for 40 minutes;

[0062] 3) Add the solution obtained in step 1) to the solution obtained in step 2), and stir with a magnetic stirrer for 2 hours;

[0063] 4) Transfer the solution obtained in step 3) to a 50ml reaction kettle, heat it in water at 190°C for 2 days, cool it down to room temperature naturally, and take out the black product;

[0064] 5) The product obtained in step 4) is centrifuged, washed with absolute ethanol for 1-2 times, and then dried in an oven at 60-70°C for 12-24 hours;

[0065] 6) heat-treat the dried product obtained in step 5) at 450°C for 5 hours in a n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com