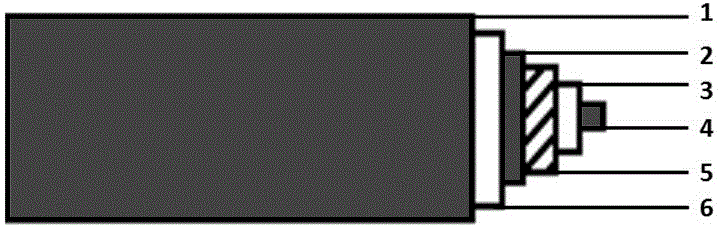

Stretchable coaxial fibrous friction electricity generating and sensing device and preparation method thereof

A technology of triboelectric power generation and sensor devices, which is applied in the direction of triboelectric generators, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems such as unsuitable for large-scale application, complicated preparation process, and unsuitable for wearing, and achieve low Cost, excellent performance, scientific and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

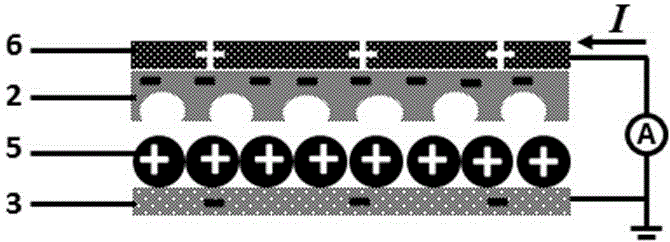

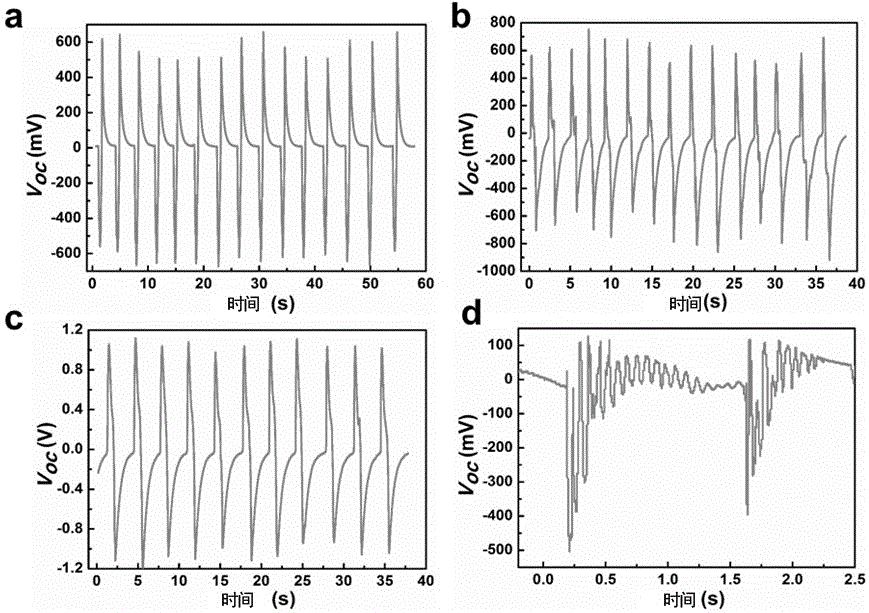

Method used

Image

Examples

Embodiment 1

[0036] (1) Preparation of fibrous elastic substrate: Polydimethylsiloxane and crosslinking agent were formulated into a solution with a mass percentage concentration of 9%, and the solution was injected into a heat shrinkable tube with an inner diameter of 0.5 mm, and cured at 80 °C 2h, peel off the outer layer of heat-shrinkable tube to obtain a fibrous polydimethylsiloxane elastic substrate;

[0037] (2) Preparation of flexible carbon nanotube inner electrode: using the fibrous polydimethylsiloxane elastic substrate prepared in step (1), the oriented carbon nanotube film was pulled out from the carbon nanotube array obtained by the vapor phase chemical deposition method and Attached to the fibrous elastic substrate, use a stepping motor on the translation platform to evenly wrap the carbon nanotube film on the elastic substrate. The motor speed is 1000r / min, and the number of wrapping layers is 4 layers. The nanotubes shrink to dense, and the flexible fibrous carbon nanotube...

Embodiment 2

[0042] (1) Preparation of fibrous elastic substrate: Polydimethylsiloxane and cross-linking agent are formulated into a solution with a concentration of 9% by mass, and the solution is injected into a heat shrinkable tube with an inner diameter of 1.0 mm, and cured at 80 °C After 2.5 h, peel off the outer heat-shrinkable tube to obtain a fibrous polydimethylsiloxane elastic substrate;

[0043] (2) Preparation of flexible carbon nanotube inner electrode: use the fibrous polydimethylsiloxane elastic substrate prepared in step (1); pull out the oriented carbon nanotube film from the carbon nanotube array obtained by the vapor phase chemical deposition method and Attached to the fibrous elastic substrate, the carbon nanotube film is evenly wrapped on the elastic substrate by using a stepping motor on the translation platform. The motor speed is 1500r / min, and the number of wrapping layers is 5 layers. The nanotubes shrink to dense, and the inner electrode of flexible carbon nanotu...

Embodiment 3

[0048] (1) Preparation of fibrous elastic substrate: Polydimethylsiloxane and crosslinking agent are formulated into a solution with a concentration of 9% by mass, and the solution is injected into a heat-shrinkable tube with an inner diameter of 1.5 mm, and cured at 80 °C 3 h, peel off the outer heat-shrinkable tube to obtain a fibrous polydimethylsiloxane elastic substrate;

[0049] (2) Preparation of flexible carbon nanotube inner electrode: use the fibrous polydimethylsiloxane elastic substrate prepared in step (2); pull out the oriented carbon nanotube film from the carbon nanotube array obtained by the vapor phase chemical deposition method and Attached to the fibrous elastic substrate, and then use a stepping motor on the translation platform to evenly wrap the carbon nanotube film on the elastic substrate. The motor speed is 2000r / min, and the number of wrapping layers is 6 layers. The carbon nanotubes shrink to dense, and the flexible fibrous carbon nanotube inner ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com