Preparation method of nano black phosphorus

A black phosphorus and nano technology, applied in the field of preparation of nano black phosphorus, can solve the problem of not being the only one, and achieve the effect of high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A preparation method of nano black phosphorus, the selected equipment is the invention patent "one-axis multi-cylinder multi-dimensional ball hammer type high-energy micro-nano ball mill, patent number 201410391780.7, including the following steps:

[0025] 1) Fill the grinding tank with raw material red phosphorus and spherical grinding medium, and complete the cover. The amount of raw material red phosphorus is 1 / 3 of the volume of the grinding tank, and the amount of spherical grinding medium is 1 / 3 of the capacity of the grinding tank; The composition is: 1 / 3 of 10 mm diameter, 1 / 3 of 8 mm diameter, 1 / 3 of 5 mm diameter; or 1 / 3 of 12 mm diameter, 1 / 3 of 10 mm diameter, and 1 / 3 of 8 mm diameter;

[0026] 2) Vacuumize to 0.08-0.1Pa, add argon or other inert gas to positive pressure of 0.08-0.1Pa, and then perform ultra-high energy ball milling at a frequency of 800 times / min to 1600 times / min;

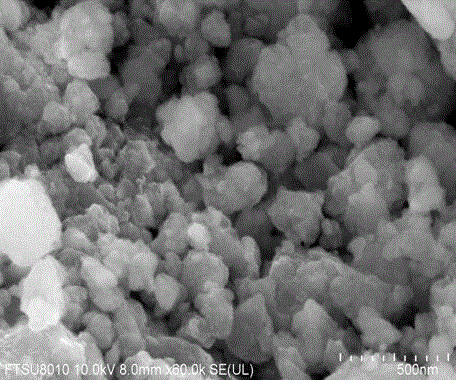

[0027] 3) Continuous ball milling for 8-10 hours. After unloading the tan...

Embodiment 1

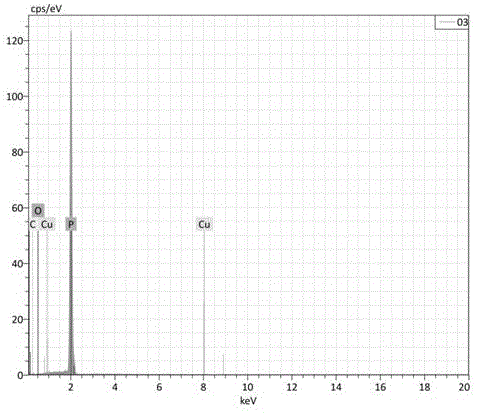

[0036] Put 100g of red phosphorus and 5g of red copper powder into a 0.5L copper mill jar, add 150g of red copper balls with a diameter of 10mm, 150g of red copper balls with a diameter of 8mm, and 150g of red copper with a diameter of 5mm. Argon Pa, then install the grinding balls on the wheel disc of the Nano Ferris Mill, fix it firmly, adjust it to 100 times / min after starting the machine, unload the tank for 10 hours of continuous ball milling, put the grinding tank in the vacuum glove box, put the glove box After evacuating and adding argon, open the lid of the grinding tank to sieve the ball material, pack and seal the material, and then take it out from the glove box to obtain crystalline black phosphorus of about 100-300 nanometers. The composition analysis shows that the phosphorus content is 90%. Contains 10% copper.

Embodiment 2

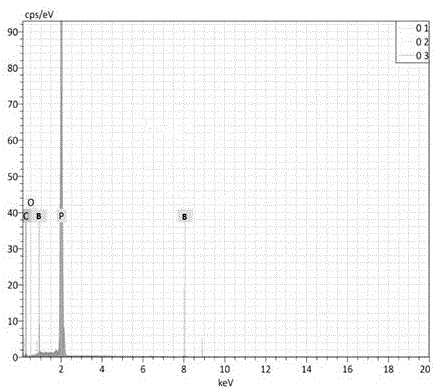

[0038] Add 100g of red phosphorus and 10g of boron nitride into the silicon nitride grinding tank, add 150g of silicon nitride balls with a diameter of 10mm, 150g of silicon nitride balls with a diameter of 8mm and 150g of silicon nitride balls with a diameter of 5mm, and vacuumize the tank to 0.08-0.1Pa, then add argon gas to 0.08-0.1Pa, then put the mill tank on the wheel of the Nano Ferris Mill, fix it firmly, turn it on and adjust it to 900 times / min, continue ball milling for 10 hours, unload the tank, and put the mill Put the tank into a vacuum glove box, vacuumize the glove box and add argon, open the lid of the grinding tank, sieve the ball material, put the material into the bottle and seal it, and then take it out of the glove box to obtain 100-300 Crystalline black phosphorus of about nanometers, composition analysis contains 90% phosphorus and 10% boron.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com