Damp-proof graphene heat dissipation film

A graphene heat-dissipating film and graphene technology, which is applied in the field of moisture-proof graphene composite heat-dissipating film, can solve the problems of poor weather resistance and affect the use effect of the heat-dissipating film, and achieve the effect of good heat-dissipating effect and improving heat-dissipating performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

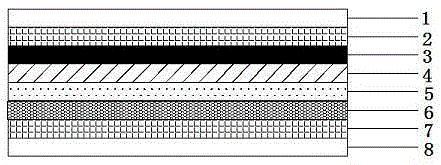

[0023] The invention provides a moisture-proof graphene heat dissipation film, such as figure 1 As shown, from top to bottom, it includes a release film layer 1, a thermally conductive adhesive layer 2, a graphene heat dissipation layer 3, an isolation coating 4, a polyester film substrate layer 5, a water-absorbing resin layer 6, a second thermally conductive adhesive layer 7, The second release film layer 8 .

[0024] In the present invention, the heat dissipation layer 3 containing graphene is used as the main structure, and the polyester film substrate layer 5 is used as the supporting layer structure. The thickness of the polyester film substrate layer 5 is 25 μm to 100 μm. One side of the substrate layer 5 is coated with an isolation coating 4, and the other side of the polyester film substrate layer 5 is provided with a water-absorbing resin layer 6, and the water-absorbing resin layer is polyacrylic acid sodium salt, polyacrylonitrile hydrolyzate, vinyl acetate One of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com