Active porous catalytic material and preparation method thereof

A catalytic material and active technology, applied in the field of active porous catalytic materials and their preparation, can solve the problems of small pores and affect the cracking reaction of macromolecules, and achieve the effect of reducing the cost of preparation, increasing the benefit space, and strong cracking ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This example illustrates the preparation of the active porous catalytic material provided by the present invention.

[0033] with Al 2 (SO 4 ) 3 Solution (concentration 50gAl 2 O 3 / L) and ammonia water (25% by mass) were used as the raw materials for the reaction, and the Al 2 (SO 4 ) 3 The solution and ammonia water are added at the same time, and they are co-flowed to form a gel. 2 / L, suspended solids concentration 100mg / L), then heat up to 60 ° C for ageing for 4 hours; after filtration, the obtained solid precipitate is precipitated according to the dry basis of the precipitate: ammonium salt: H 2 The weight ratio of O=1:1:10 is exchanged at 60° C. for 1 hour, filtered and washed with water, and the ammonium exchange is repeated once.

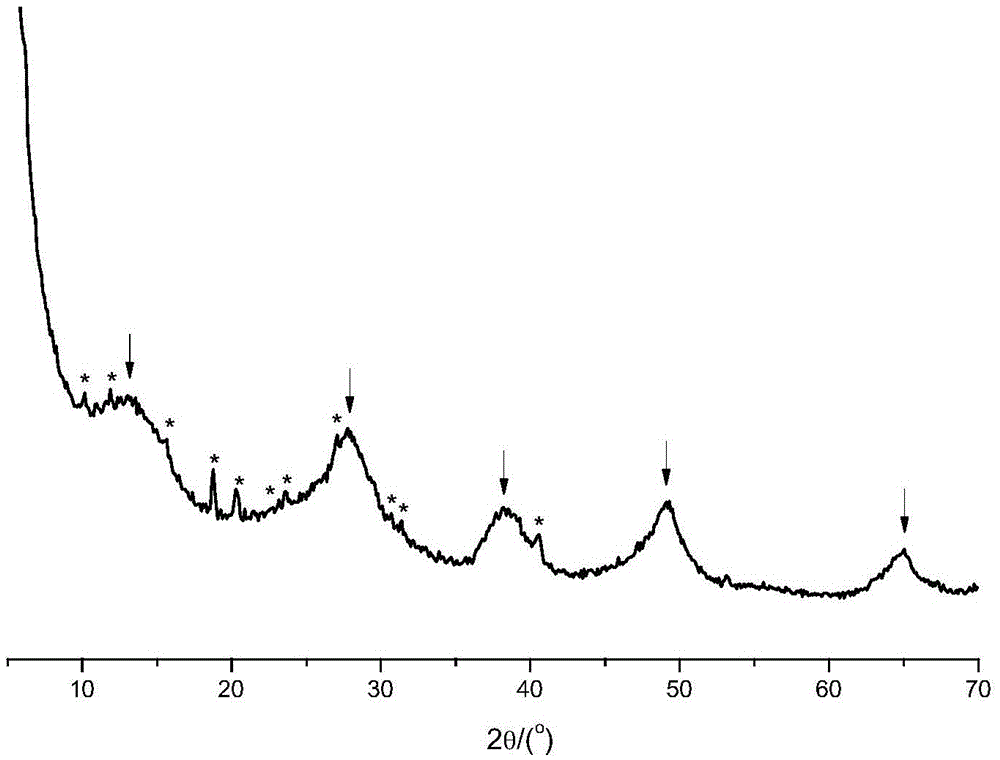

[0034] The main structure of APM-1 is pseudo-boehmite crystal phase structure, and there is a small amount of FAU structure of Y-type molecular sieve. Its X-ray diffraction spectrum is shown in figure 1 , the diffraction p...

Embodiment 2

[0036] This example illustrates the preparation of the active porous catalytic material provided by the present invention.

[0037] with Al 2 (SO 4 ) 3 The solution and ammonia water are used as the raw materials for the reaction, and the co-current gelation method is adopted, and the Al is mixed under vigorous stirring. 2 (SO 4 ) 3 The solution and ammonia water were mixed to form a gel, the gelling temperature was controlled to be 35°C, the pH value of the gel-forming system was 8.5, and an appropriate amount of NaY washing filtrate (concentration 40g SiO) was added after gelling for a certain period of time. 2 / L, suspended solids concentration 5400mg / L), then heated to 70 ℃ for 2 hours; after filtration, the obtained solid precipitate was filtered according to the dry basis of the precipitate: ammonium salt: H 2 The weight ratio of O=1:0.7:15 is exchanged at 50° C. for 0.5 hours, filtered and washed, and the ammonium exchange is repeated once.

[0038] The main struc...

Embodiment 3

[0044] This example illustrates the preparation of the active porous catalytic material provided by the present invention.

[0045] with Al 2 (SO 4 ) 3 Solution and NaAlO 2 Solution (concentration 102gAl 2 O 3 / L) is the raw material for the reaction, and NaAlO was stirred vigorously at 50 °C 2 solution added to Al 2 (SO 4 ) 3 Neutralize and gel in the solution, and the gel pH value is controlled at 10.5, and then the mixed solution of quantitative NaY crystallization mother liquor and washing filtrate (concentration 34gSiO) is added. 2 / L, suspended solids concentration 2100mg / L), and warmed up to 80 ℃ for 1 hour; after filtration, the obtained solid precipitate was filtered according to the dry basis of the precipitate: ammonium salt: H 2 The weight ratio of O=1:0.8:15 is exchanged at room temperature for 1 hour, filtered and washed to obtain the active porous catalytic material provided by the present invention, which is designated as APM-3.

[0046] The main stru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com