An aqueous solution-based broadband wave-absorbing metamaterial and its preparation method

An aqueous solution and metamaterial technology, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as difficult to meet engineering application requirements, high density of magnetic materials, complex preparation process, etc., to achieve easy scale production and application, raw materials Easy and mature preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

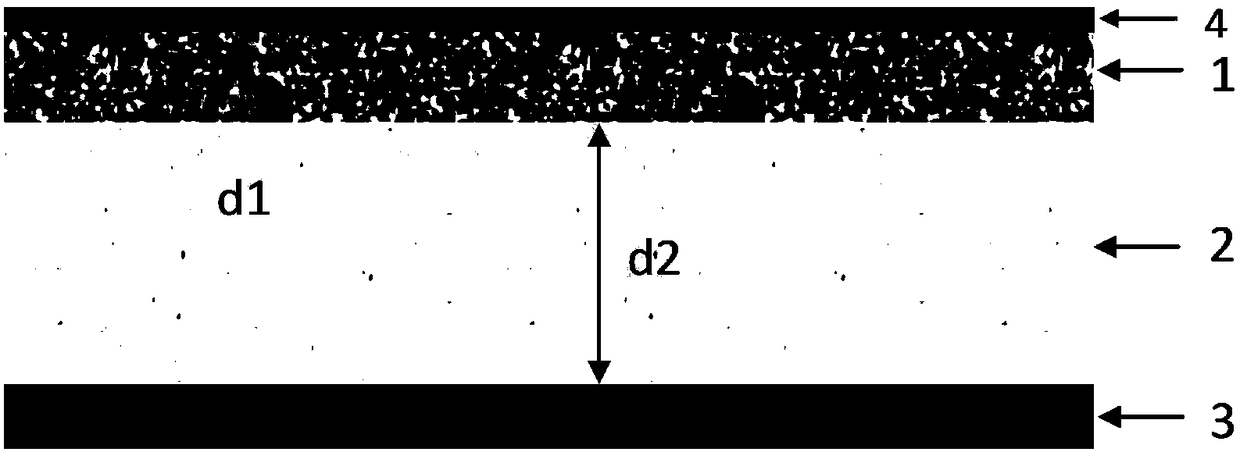

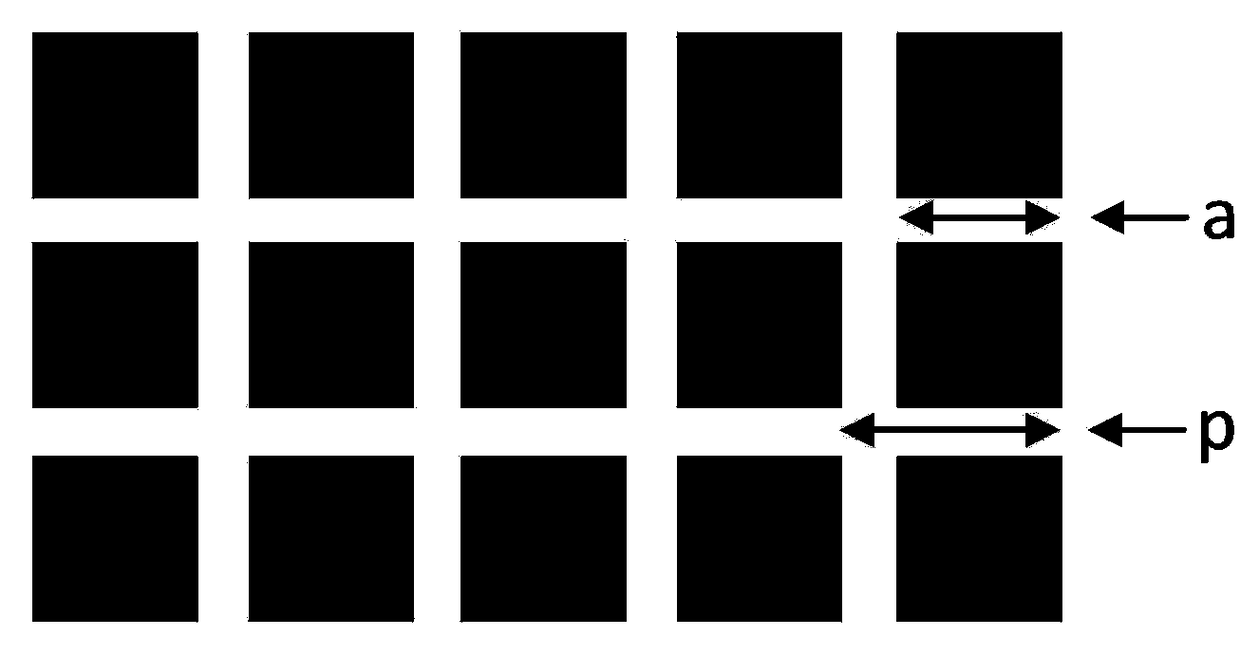

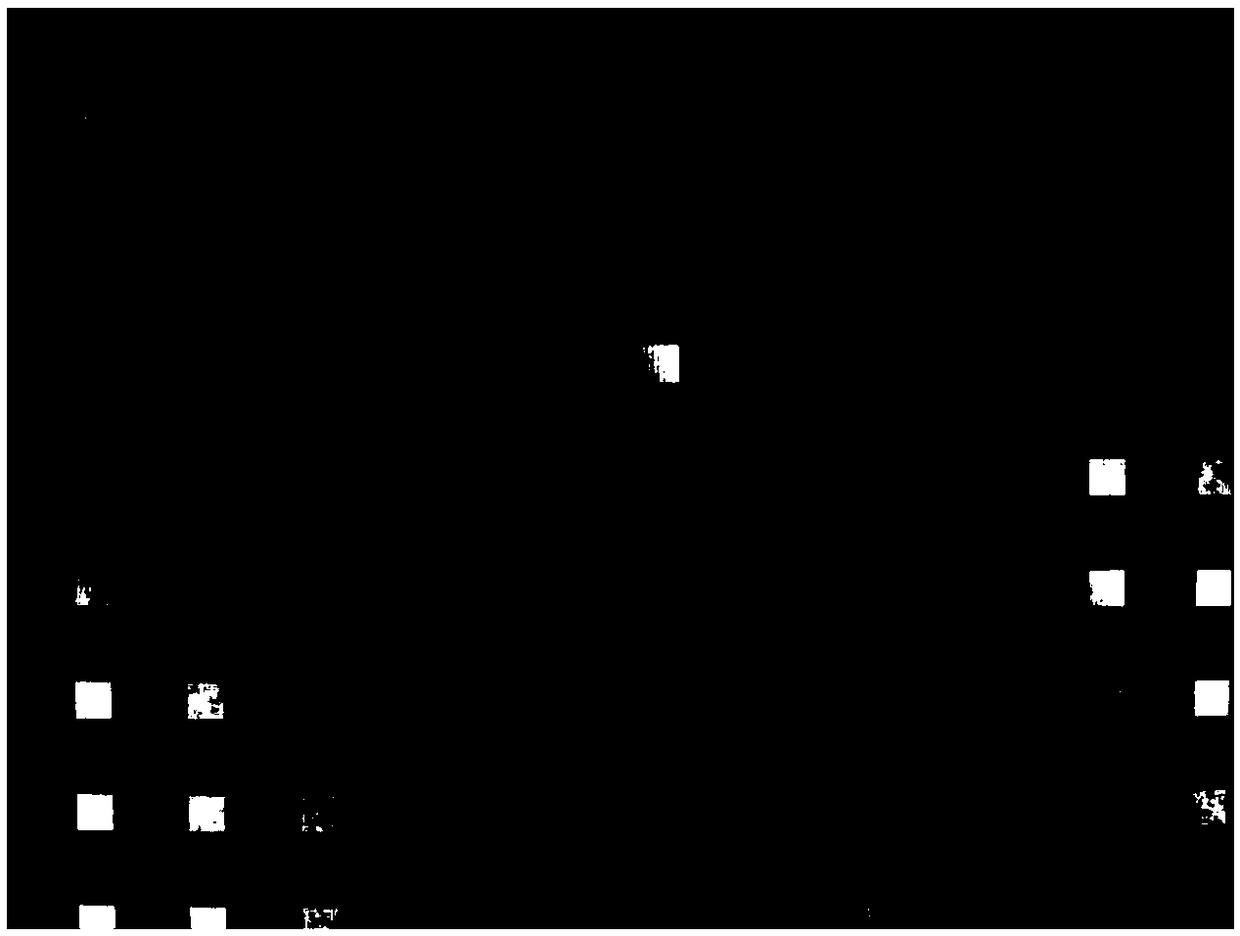

[0032] Combine Figure 1-Figure 5 As shown, Embodiment 1 of the present invention provides an aqueous solution-based broadband microwave absorbing metamaterial, which includes a conductive reflective layer 3, a dielectric base layer, and a periodic array layer 4 stacked from bottom to top. The dielectric base layer is composed of a composite material frame 1 and The composite frame 1 is composed of deionized water 2 injected, the thickness d1 of the composite frame 1 is 2.5mm, the injection depth d2 of the deionized water 2 is 1.0mm, and the deionized water 2 is in contact with the upper surface of the conductive reflective layer 3. A periodic array layer 4 is provided on the top surface of the composite material frame 1, and the periodic array layer 4 is composed of an array of metal patches.

[0033] Specifically, the conductive reflective layer 3 is made of aluminum plate, the composite frame 1 is made of glass fiber reinforced epoxy resin composite material, the dielectric co...

Embodiment 2

[0042] Embodiment 2 of the present invention provides an aqueous solution-based broadband microwave absorbing metamaterial, which includes a conductive reflective layer 3, a dielectric matrix layer, and a periodic array layer 4 stacked sequentially from bottom to top. The dielectric matrix layer is composed of a composite material frame 1 and a composite material frame. 1, the thickness d1 of the composite material frame 1 is 2.8mm, the injection depth d2 of the deionized water 2 is 1.2mm, and the deionized water 2 is in contact with the upper surface of the conductive reflective layer 3. The composite material A periodic array layer 4 is provided on the top surface of the frame 1, and the periodic array layer 4 is composed of an array of metal patches.

[0043] Specifically, the conductive reflective layer 3 is made of carbon fiber composite material, the composite frame 1 is made of quartz fiber reinforced polyimide composite material, the dielectric constant of the quartz fiber...

Embodiment 3

[0051] Embodiment 3 of the present invention provides an aqueous solution-based broadband wave-absorbing metamaterial, which includes a conductive reflective layer 3, a dielectric matrix layer, and a periodic array layer 4 stacked from bottom to top. The dielectric matrix layer is composed of a composite material frame 1 and a composite material frame. 1 is composed of deionized water 2 injected in the composite material frame 1, the thickness d1 of the composite material frame 1 is 0.8mm, the injection depth d2 of the deionized water 2 is 0.5mm, the deionized water 2 is in contact with the upper surface of the conductive reflective layer 3, and the composite material A periodic array layer 4 is provided on the top surface of the frame 1, and the periodic array layer 4 is composed of an array of metal patches.

[0052] Specifically, the conductive reflective layer 3 is made of aluminum plate, the composite frame 1 is made of alumina fiber reinforced composite material, the dielect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com