Controllable preparation method for tungsten disulfide

A technology of tungsten disulfide and silicon dioxide, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of uncontrollable growth and less tungsten disulfide, and achieve the reduction of operation steps, Simplified cleaning method, large area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

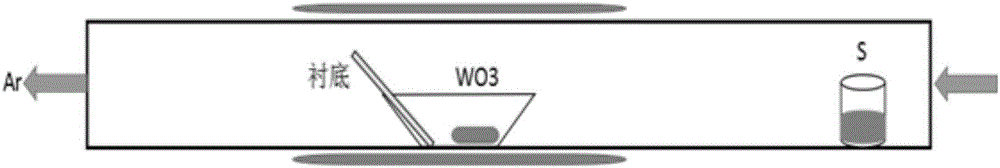

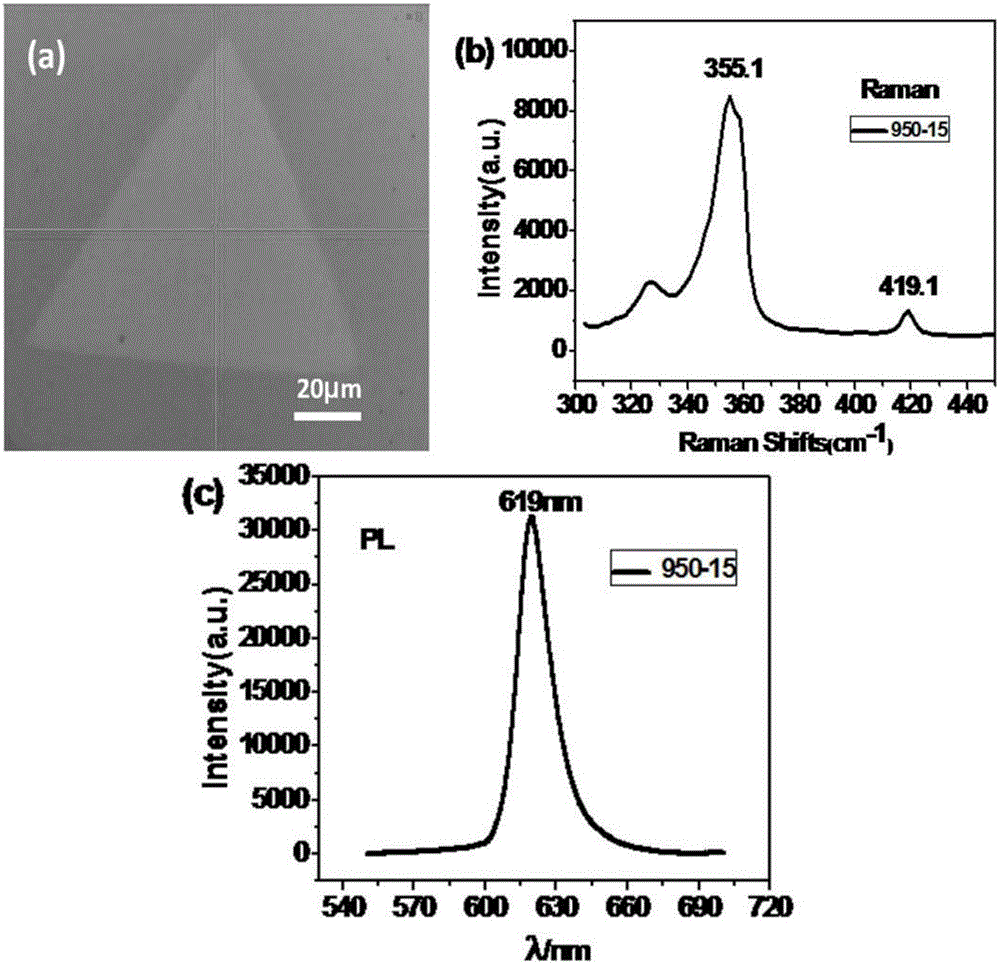

[0023] Atmospheric pressure chemical vapor deposition method is adopted; a certain amount of 0.2gWO is weighed 3 and 1gS, and placed in two quartz boats; place the quartz boat with S at 25cm from the inlet of the tube furnace; place WO 3 In a quartz boat, the cleaned silicon dioxide / silicon substrate (1 cm×1 cm) was blown dry with a nitrogen gun, and then cleaned with an oxygen plasma cleaner for 3 min. Lay the silicon wafer substrate on a quartz boat and place it in the center of the heating zone. The tube furnace was ventilated with nitrogen for 60 minutes in advance, and the nitrogen flow rate was 200 sccm, and the air in the tube was exhausted. Adjust the nitrogen flow rate to 100 sccm, raise the temperature of the tube furnace to 950° C. at a heating rate of 30° C. / min, and keep the temperature for 15 minutes. When the tube furnace cooled down to room temperature naturally, the furnace cover was opened to obtain the required samples.

Embodiment 2

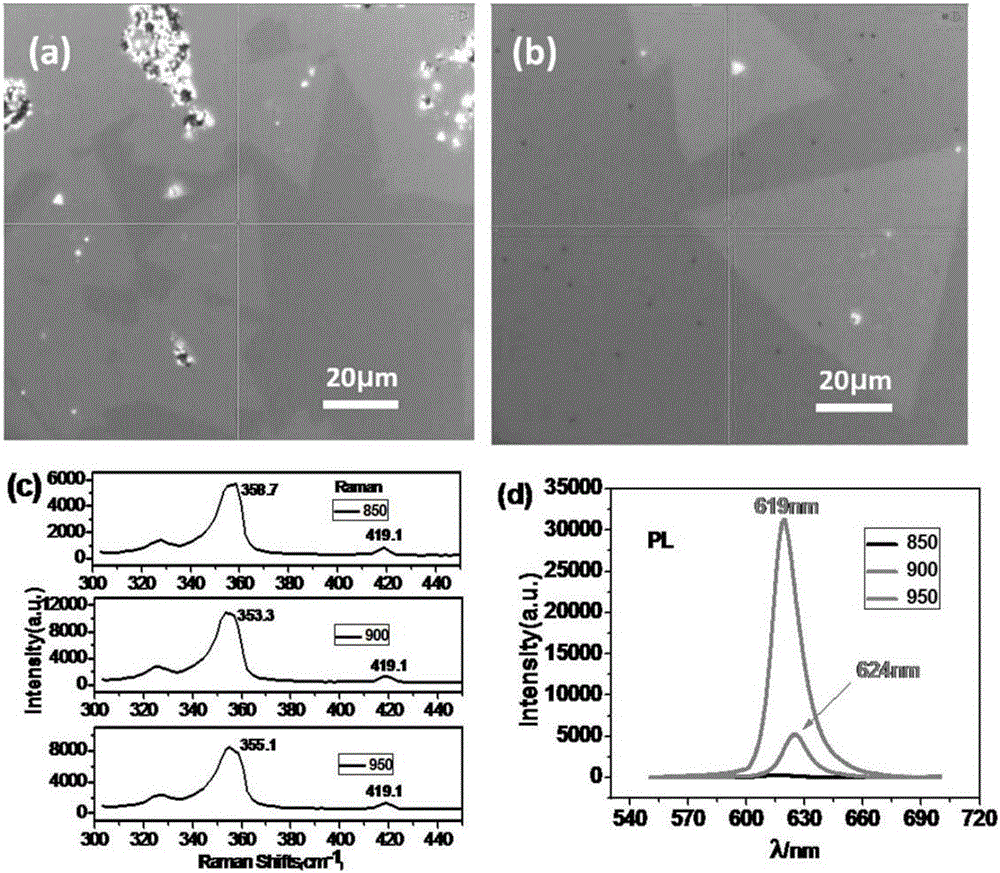

[0025] Atmospheric pressure chemical vapor deposition method is adopted; a certain amount of 0.2gWO is weighed 3 and 1gS, and placed in two quartz boats; place the quartz boat with S at 25cm from the inlet of the tube furnace; place WO 3 In a quartz boat, the cleaned silicon dioxide / silicon substrate (1 cm×1 cm) was blown dry with a nitrogen gun, and then cleaned with an oxygen plasma cleaner for 3 min. Lay the silicon wafer substrate on a quartz boat and place it in the center of the heating zone. The tube furnace was ventilated with nitrogen for 50 minutes in advance, and the nitrogen flow rate was 250 sccm, and the air in the tube was exhausted. Adjust the nitrogen flow rate to 150 sccm, raise the temperature of the tube furnace to 900° C. at a heating rate of 30° C. / min, and keep the temperature for 25 minutes. When the tube furnace cooled down to room temperature naturally, the furnace cover was opened to obtain the required samples.

Embodiment 3

[0027] Atmospheric pressure chemical vapor deposition method; weigh a certain 0.1gWO 3 and 1gS, and placed in two quartz boats; place the quartz boat with S at 25cm from the inlet of the tube furnace; place WO 3 In a quartz boat, the cleaned silicon dioxide / silicon substrate (1 cm×1 cm) was blown dry with a nitrogen gun, and then cleaned with an oxygen plasma cleaner for 3 min. Lay the silicon wafer substrate on a quartz boat and place it in the center of the heating zone. The tube furnace was ventilated with nitrogen for 60 minutes in advance, and the nitrogen flow rate was 200 sccm, and the air in the tube was exhausted. Adjust the nitrogen flow rate to 100 sccm, raise the temperature of the tube furnace to 850° C. at a heating rate of 30° C. / min, and keep the temperature for 20 minutes. When the tube furnace cooled down to room temperature naturally, the furnace cover was opened to obtain the required samples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com