Long-acting drag reduction coating and preparation method and application of long-acting drag reduction coating

A coating, long-term technology, applied in the field of materials, can solve the problems of limited preparation area and high cost, achieve excellent drag reduction performance and solve the effect of instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] Another aspect of the present invention also discloses a preparation method of a long-lasting drag-reducing coating, comprising:

[0035] (1) Immerse the nano-zinc oxide film in a treatment solution containing organosilane for modification, and obtain a coating with lipophilic and hydrophobic properties on the surface of the nano-zinc oxide film;

[0036] (2) The modified nano-zinc oxide film is immersed in the molten long-chain alkane liquid, and self-assembled to obtain a long-term drag-reducing coating.

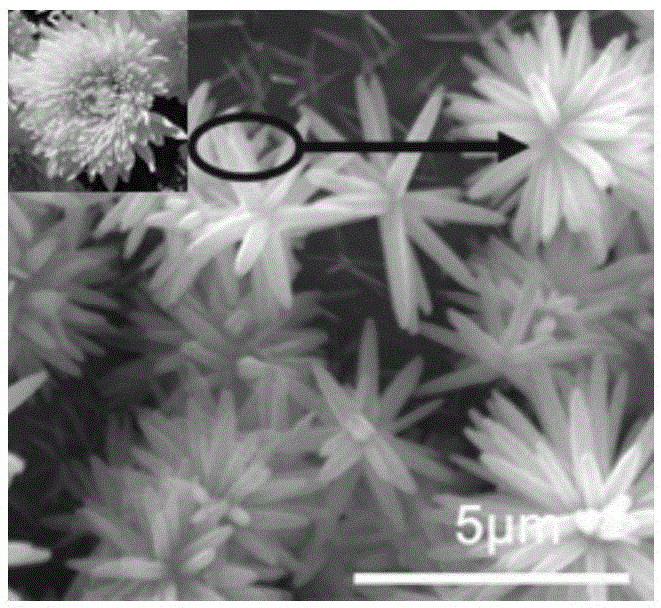

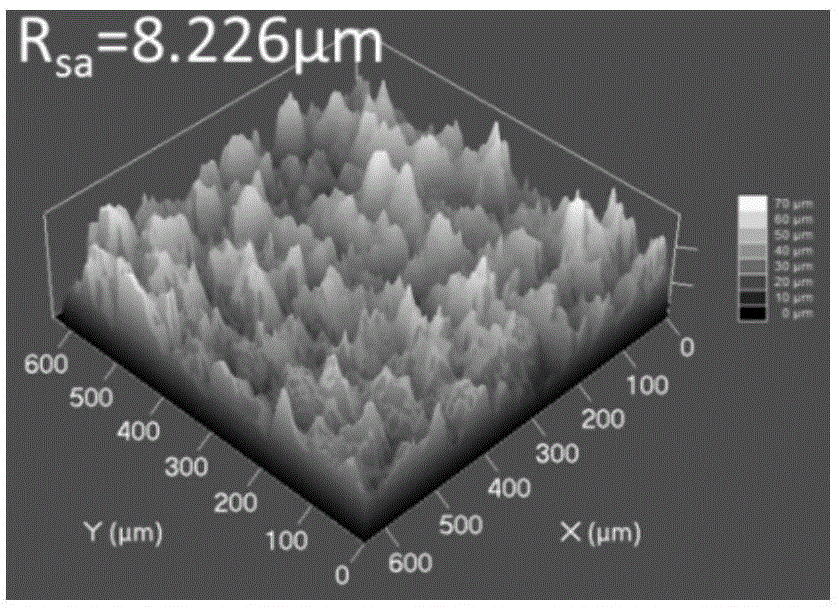

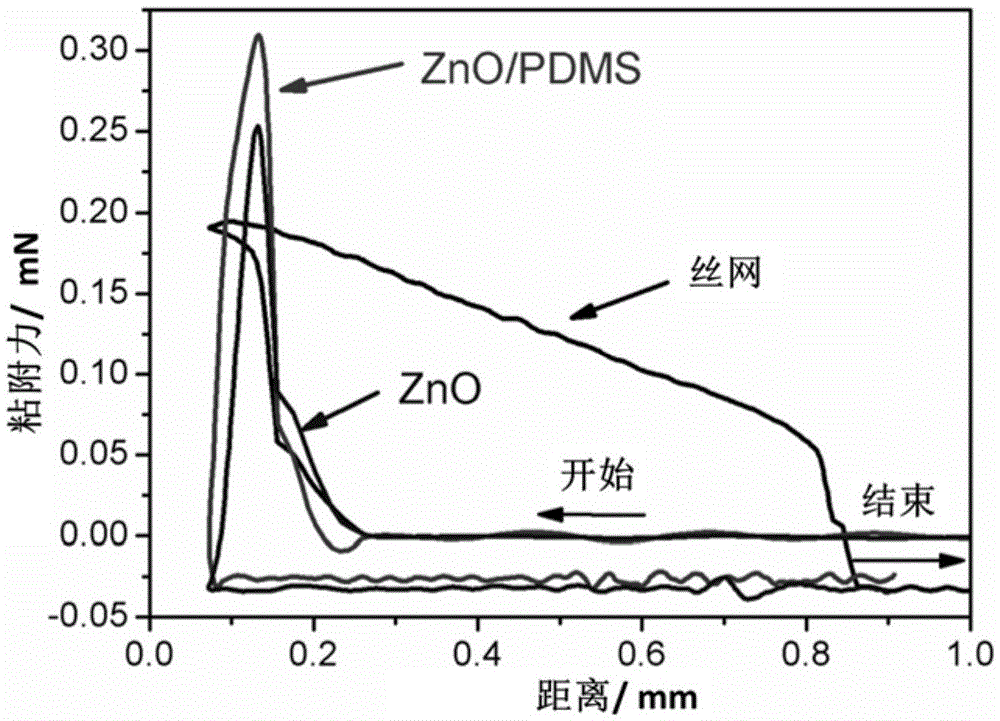

[0037] Specifically, in this case, a wire mesh was selected as the substrate, and the amphiphilic (oleophilic / hydrophilic) zinc oxide film was first prepared on the wire mesh by chemical vapor deposition technology, and then the zinc oxide film was coated with polydimethylsiloxane (PDMS). The film is modified to make it have oleophilic and hydrophobic monophilic properties. Finally, the PDMS modified zinc oxide is treated with oil (such as n-octadecane and other lon...

Embodiment 1

[0039] Example 1: The drag-reducing coating with temperature-controllable resistance is made of polydimethylsiloxane-modified zinc oxide film substrate, the surface is dip-coated with n-octadecane and other long-chain alkanes that are solid at room temperature and their mixture oils composition.

[0040] The preparation process of the drag-reducing coating with resistance temperature controllability is carried out according to the following steps:

[0041] (1) Hydrothermal method prepares zinc oxide thin film, the preparation method of zinc oxide thin film is (in 100ml solution meter): take by weighing 2.949g zinc nitrate and be dissolved in 95ml deionized water, add 0.10698g ammonium chloride, 0.6004g urea, 5ml of ammonia water, then put it into a wire mesh, control the reaction temperature to 90°C, and the reaction time is 3h, to obtain a zinc oxide film with a certain particle size and thickness;

[0042] (2) Polydimethylsiloxane modified zinc oxide film, the polydimethyls...

Embodiment 2

[0047] Example 2: The drag-reducing coating with temperature-controllable resistance is made of polydimethylsiloxane-modified zinc oxide film substrate, and the surface is dip-coated with n-octadecane and other long-chain alkanes that are solid at room temperature and their mixtures. composition.

[0048] The preparation process of the drag-reducing coating with resistance temperature controllability is carried out according to the following steps:

[0049] (1) Hydrothermal method prepares zinc oxide thin film, the preparation method of zinc oxide thin film is (in 100ml solution meter): take by weighing 2.949g zinc nitrate and be dissolved in 95ml deionized water, add 0.10698g ammonium chloride, 0.6004g urea, 5ml of ammonia water, then put it into a wire mesh, control the reaction temperature to 80°C, and the reaction time is 1h, to obtain a zinc oxide film with a certain particle size and thickness;

[0050] (2) Polydimethylsiloxane modified zinc oxide film, the polydimethyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com