Normal-temperature blackening liquid for steel and iron and application thereof

A normal temperature, steel technology, applied in the direction of metal material coating process, etc., can solve the problems of poor corrosion resistance, poor bonding force, poor gloss and other problems of film formation, achieve excellent film performance, solve poor stability, and reduce dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

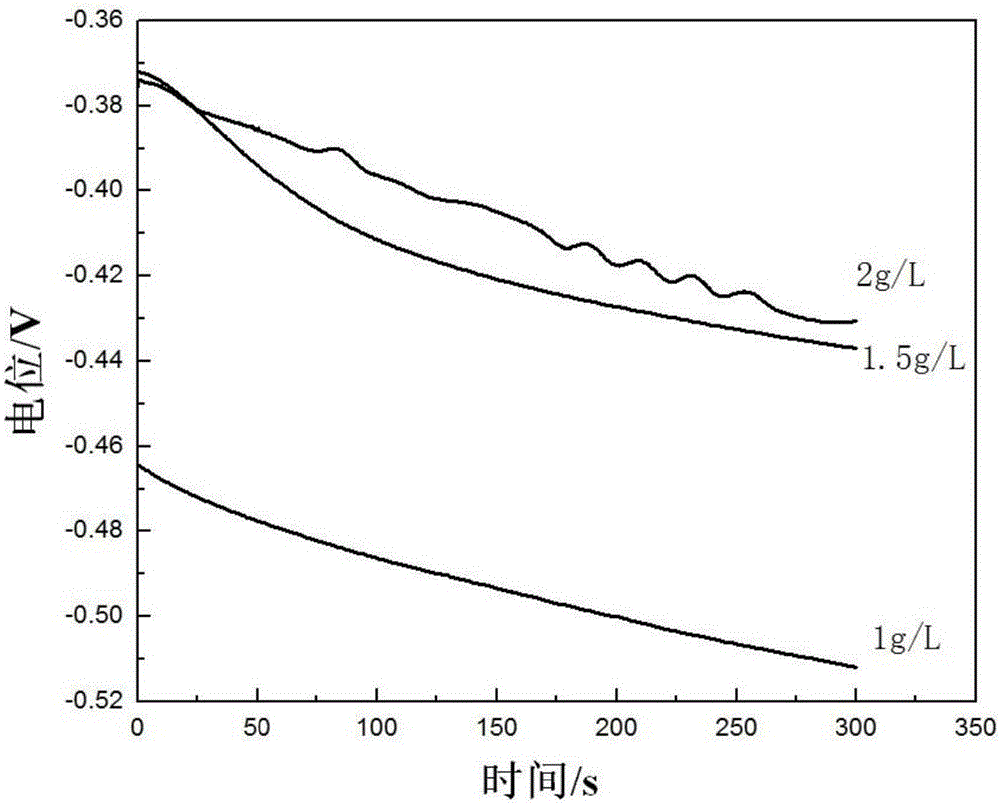

[0024] Examples 1-3: Blackening solutions containing different contents of nickel sulfate and experiments on their blackening effects.

[0025]

[0026] In order to determine the optimal content of nickel sulfate in the formula, three blackening solutions with different nickel sulfate contents were selected for parallel experiments, and the other components and dosages in the formula were kept exactly the same. Through the following process flow, the three kinds of blackening solutions are compared and analyzed:

[0027] (1) Preprocessing:

[0028] Washing, pickling (removing oil and rust) and cleaning the surface of steel parts.

[0029] (2) Blackening treatment:

[0030] Immerse the pretreated specimens in the three blackening solutions made of the components in the above table respectively, control the blackening time to 16min, and the blackening temperature to 50°C.

[0031] (3) Post-processing:

[0032] Seal and passivate the blackened specimen.

[0033] Measure t...

Embodiment 4-8

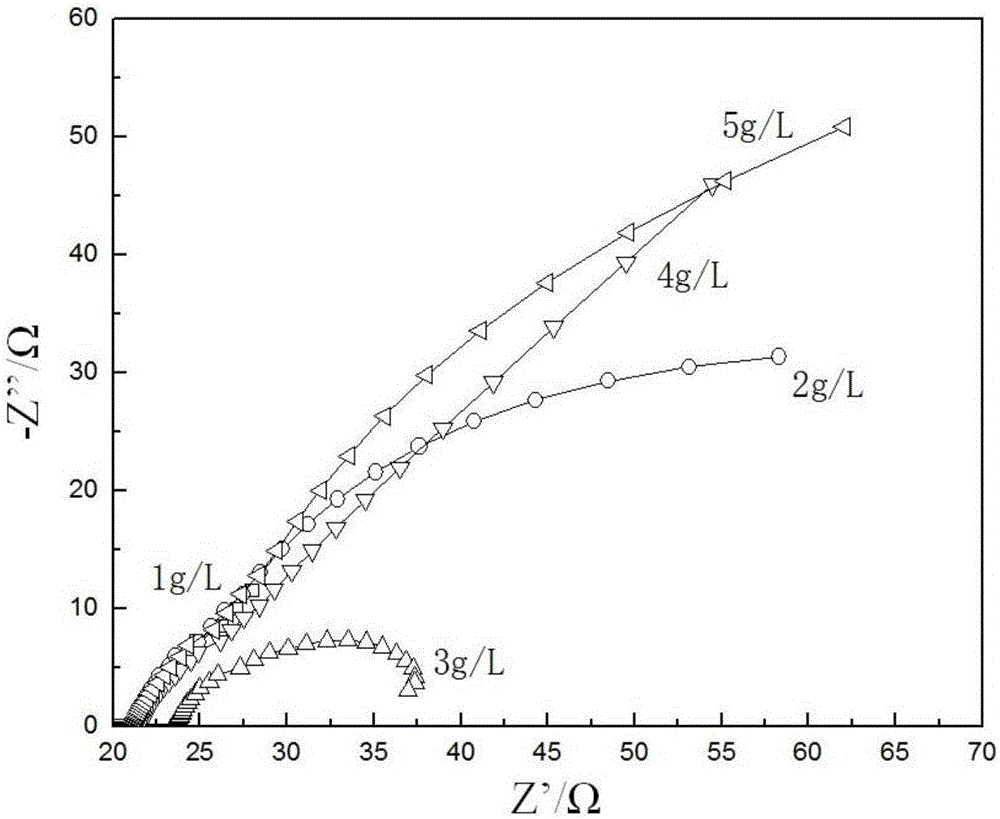

[0034] Examples 4-8: Experiments on blackening solutions containing different contents of citric acid and their blackening effects.

[0035]

[0036] In order to determine the optimal content of citric acid in the formula, five blackening solutions with different citric acid content were selected for parallel experiments, and the other components and dosages in the formula were kept exactly the same. Through the following process, the five blackening solutions were compared and analyzed:

[0037] (1) Preprocessing:

[0038] Washing, pickling (removing oil and rust) and cleaning the surface of steel parts.

[0039] (2) Blackening treatment:

[0040] Immerse the pretreated specimens in the three blackening solutions made of the components in the above table respectively, control the blackening time to 16min, and the blackening temperature to 50°C.

[0041] (3) Post-processing:

[0042] Seal and passivate the blackened specimen.

[0043] Measure the AC impedance curve in ...

Embodiment 9-12

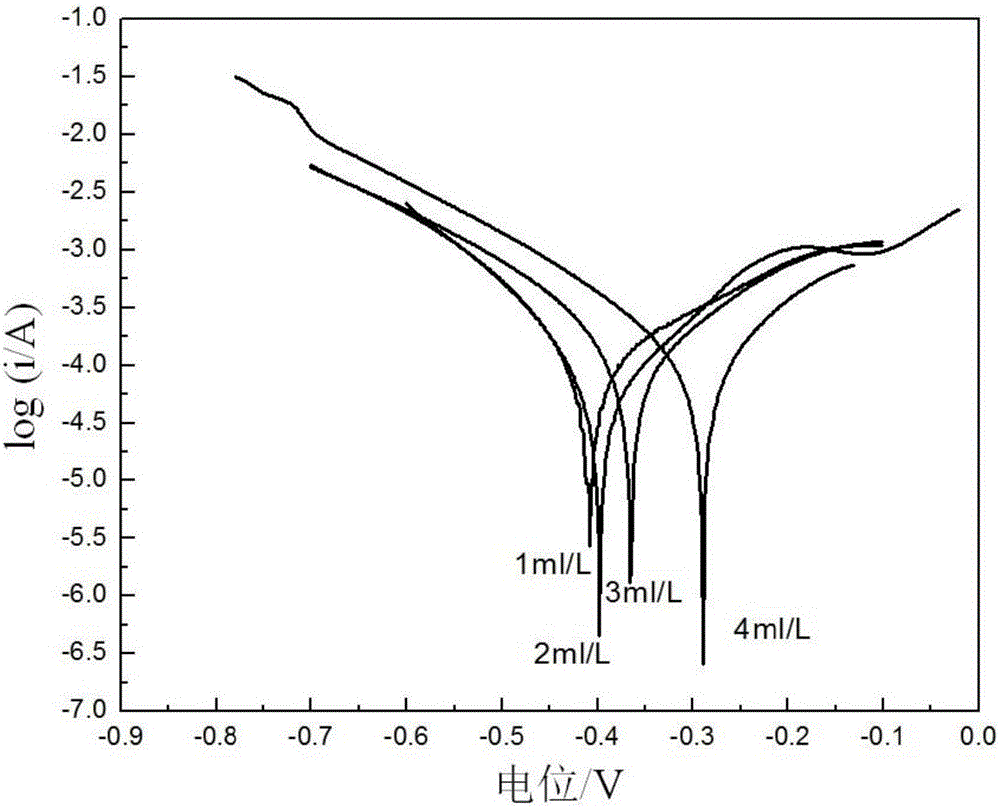

[0044]Examples 9-12: Experiments on blackening solutions containing different contents of OP-10 and their blackening effects.

[0045]

[0046] In order to determine the optimal content of OP-10 in the formula, four blackening solutions with different OP-10 contents were selected for parallel experiments, and the other components and dosages in the formula were kept exactly the same. Through the following process flow, 4 kinds of blackening solutions are compared and analyzed:

[0047] (1) Preprocessing:

[0048] Washing, pickling (removing oil and rust) and cleaning the surface of steel parts.

[0049] (2) Blackening treatment:

[0050] Immerse the pretreated specimens in the three blackening solutions made of the components in the above table respectively, control the blackening time to 16min, and the blackening temperature to 50°C.

[0051] (3) Post-processing:

[0052] Seal and passivate the blackened specimen.

[0053] Measure the Tafel curve of the blackened film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com