Compound type circulating water bactericide and preparation method

A technology of circulating water and fungicides, applied in the direction of fungicides, botanical equipment and methods, biocides, etc., can solve the problems of single species of fungicides, large dosage, high cost, etc., and achieve excellent killing effect and killing speed Fast, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

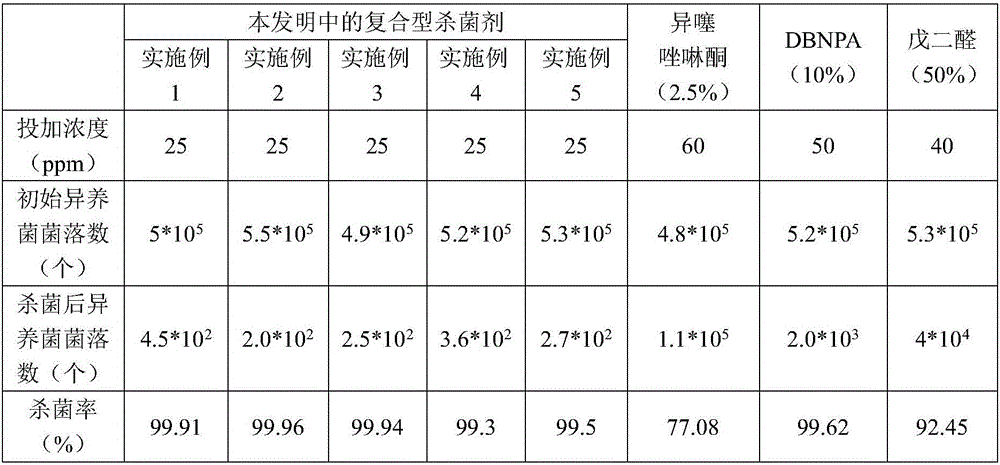

Examples

Embodiment 1

[0030] A compound circulating water bactericide, composed of the following components in parts by weight: 5 parts of 2,4,5,6-tetrachloro-1,3-benzenedicarbonitrile, 1-(2-cyano-2- 5 parts of methoxyimino)-3-ethylurea, 10 parts of dimethylformamide, 5 parts of ethylene glycol, 5 parts of 10% sulfuric acid, 10 parts of manganese dithiocarbamate, 10 parts of dithiocarbamic acid 3 parts of zinc, 57 parts of distilled water.

[0031] The preparation method is as follows:

[0032] S1: Add 2,4,5,6-tetrachloro-1,3-benzenedicarbonitrile into the reaction kettle, then add dimethylformamide and ethylene glycol into the reaction kettle, and stir thoroughly for 15 minutes;

[0033] S2: Add 10% sulfuric acid to the above reaction kettle, and fully stir for 25 minutes;

[0034] S3: Add 1-(2-cyano-2-methoxyimino)-3-ethylurea to the above reaction kettle, and stir for 15 minutes;

[0035] S4: Add manganese dithiocarbamate to the above reaction kettle, and stir for 15 minutes;

[0036] S5: Ad...

Embodiment 2

[0040] A compound circulating water bactericide, which consists of the following components in parts by weight: 15 parts of 2,4,5,6-tetrachloro-1,3-benzenedicarbonitrile, 1-(2-cyano-2- 8 parts of methoxyimino)-3-ethylurea, 25 parts of dimethylformamide, 12 parts of ethylene glycol, 10 parts of 10% sulfuric acid, 15 parts of manganese dithiocarbamate, dithiocarbamic acid 8 parts of zinc, 7 parts of distilled water.

[0041] The preparation method is as follows:

[0042] S1: Add 2,4,5,6-tetrachloro-1,3-benzenedicarbonitrile into the reaction kettle, then add dimethylformamide and ethylene glycol into the reaction kettle, and stir thoroughly for 25 minutes;

[0043] S2: Add 10% sulfuric acid to the above reaction kettle, and fully stir for 15 minutes;

[0044] S3: Add 1-(2-cyano-2-methoxyimino)-3-ethylurea to the above reaction kettle, and stir for 20 minutes;

[0045] S4: Add manganese dithiocarbamate to the above reaction kettle, and stir for 10 minutes;

[0046] S5: Add zi...

Embodiment 3

[0050] A compound circulating water bactericide, composed of the following components in parts by weight: 10 parts of 2,4,5,6-tetrachloro-1,3-benzenedicarbonitrile, 1-(2-cyano-2- 6 parts of methoxyimino)-3-ethylurea, 12 parts of dimethylformamide, 10 parts of ethylene glycol, 8 parts of 10% sulfuric acid, 12 parts of manganese dithiocarbamate, dithiocarbamic acid 5 parts of zinc, 37 parts of distilled water.

[0051] The preparation method is as follows:

[0052] S1: Add 2,4,5,6-tetrachloro-1,3-benzenedicarbonitrile into the reaction kettle, then add dimethylformamide and ethylene glycol into the reaction kettle, and stir thoroughly for 20 minutes;

[0053] S2: Add 10% sulfuric acid to the above reaction kettle, and fully stir for 20 minutes;

[0054] S3: Add 1-(2-cyano-2-methoxyimino)-3-ethylurea to the above reaction kettle, and stir for 17 minutes;

[0055] S4: Add manganese dithiocarbamate to the above reaction kettle, and stir for 13 minutes;

[0056] S5: Add zinc dit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com