Composite coalescence material for water deoiling

A composite coalescence and deoiling technology, applied in the field of water treatment, to achieve huge benefits and reduce treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

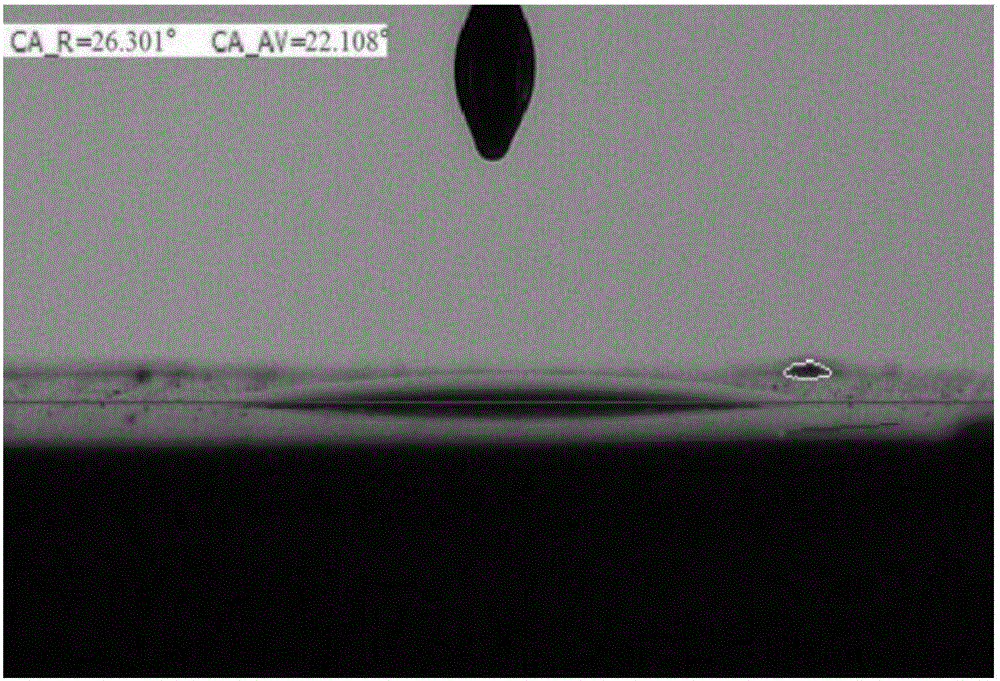

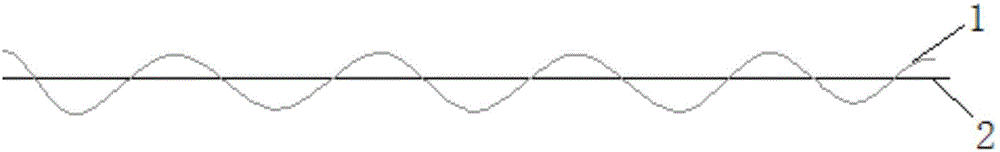

[0040]The wastewater in the wastewater mixing tank of a petrochemical enterprise factory in Shandong Province, after preliminary filtration, has an oil content of 1600-2000ppm. Using the method of the invention, firstly, ultrasonic cleaning is performed on polypropylene fibers to remove oil stains on the surface, and then a mixed solution of 5% potassium permanganate and 0.2mol / L sulfuric acid is used as an initiator, combined with 5% ethyl acrylate The solution is subjected to graft copolymerization to modify the fibers. On the basis of filtration, cleaning and drying, the modified polypropylene fibers and metal wires are mixed in a ratio of 1:1 to make lipophilic and hydrophobic composite fibers, and the lipophilic and hydrophobic composite fibers are mixed with hydrophilic The oleophobic glass fibers are woven according to the rice shape, the quantity ratio is 2:1, the weaving angle θ is 30 degrees, and the 300mm composite coalescing material is woven, and then the wastewat...

Embodiment 2

[0043] The oily wastewater from a refinery in Wuhan has an oil content of 30%-40%, a moisture content of 50%-60%, and solids and other components of 10%. The oil content of the wastewater after preliminary coagulation, sedimentation and desliming is 500-1800ppm. Using the method of the invention, firstly, ultrasonic cleaning is performed on polypropylene fibers to remove oil stains on the surface, and then a mixed solution of 5% potassium permanganate and 0.2mol / L sulfuric acid is used as an initiator, combined with 4% ethyl acrylate The solution is subjected to graft copolymerization to modify the fibers. On the basis of filtration, cleaning and drying, the modified polypropylene fibers and metal wires are mixed in a ratio of 2:1 to make lipophilic and hydrophobic composite fibers, and the lipophilic and hydrophobic composite fibers are mixed with hydrophilic The oleophobic glass fibers are woven according to the rice shape, the quantity ratio is 1:1, the weaving angle θ is ...

Embodiment 3

[0046] After preliminary treatment of the oil extraction wastewater from an oil extraction plant in Heilongjiang Province, the oil content in the oily wastewater is 2000-2300 ppm. Using the method of the invention, firstly, ultrasonic cleaning is performed on polypropylene fibers to remove surface oil stains, and then a mixed solution of 5% potassium permanganate and 0.2mol / L sulfuric acid is used as an initiator, combined with 6% ethyl acrylate The solution is subjected to graft copolymerization to modify the fibers. On the basis of filtration, cleaning and drying, the modified polypropylene fibers and metal wires are mixed and weaved in a ratio of 1:1 to obtain lipophilic and hydrophobic composite fibers. The lipophilic and hydrophobic composite fibers and the hydrophilic and oleophobic glass fibers are woven according to the rice shape, the quantity ratio is 3:1, the weaving angle θ is 25 degrees, and the weaving is a water-degreasing composite coalescing filler. The 280mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com