Energy-saving type temperature swing adsorption system and method for separating carbon dioxide in industrial flue gas

A technology for industrial flue gas and carbon dioxide, applied in separation methods, chemical instruments and methods, chemical industry, etc., can solve the problem of high energy consumption and achieve the effect of improving adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

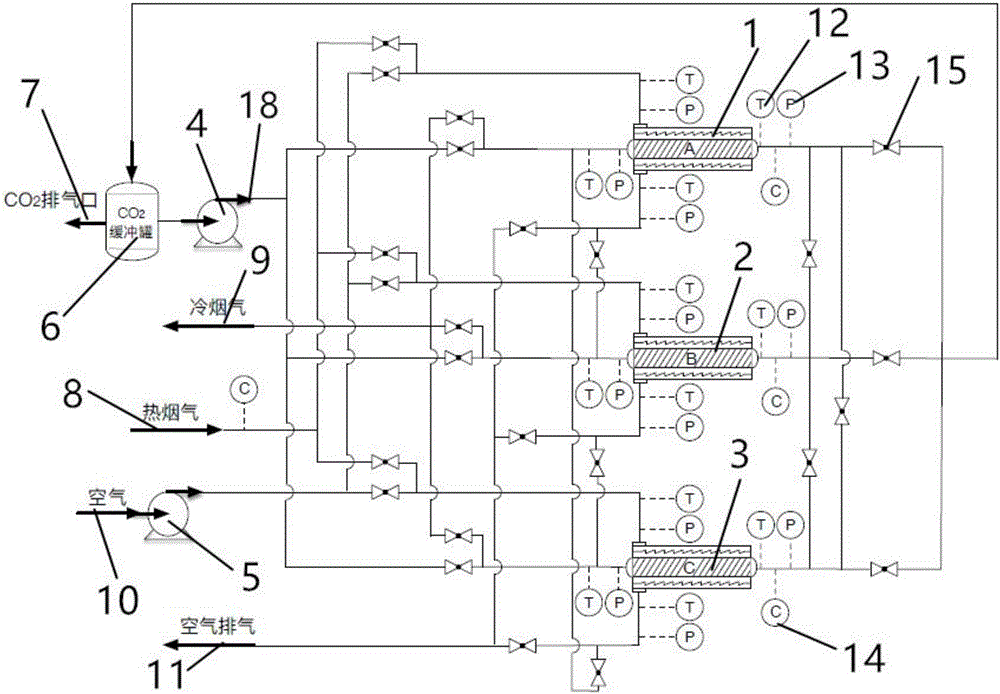

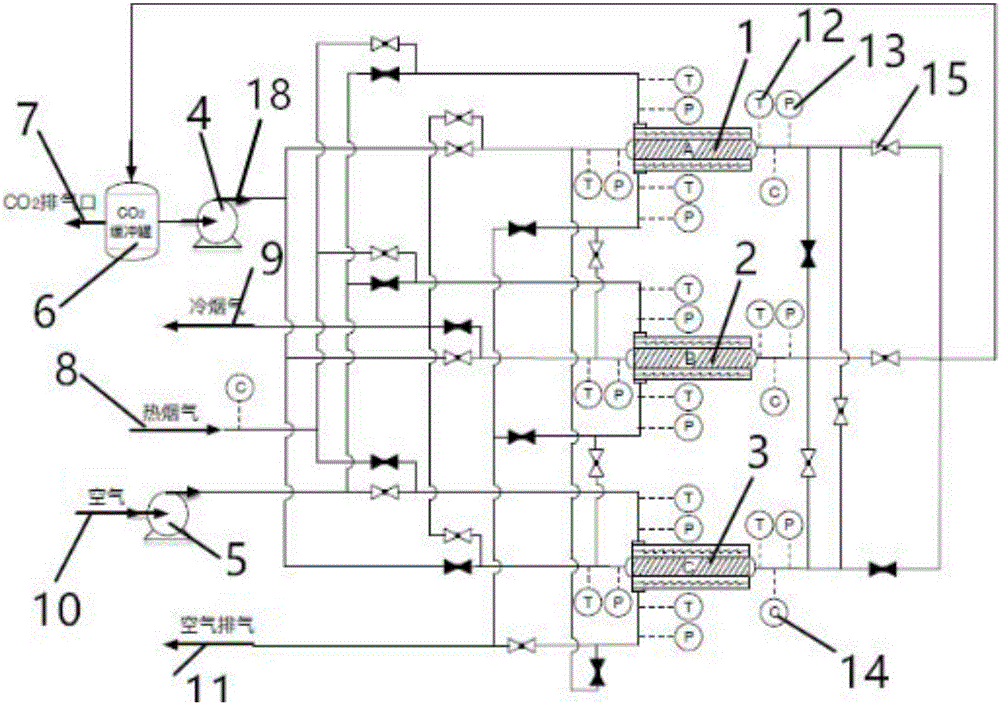

[0049] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

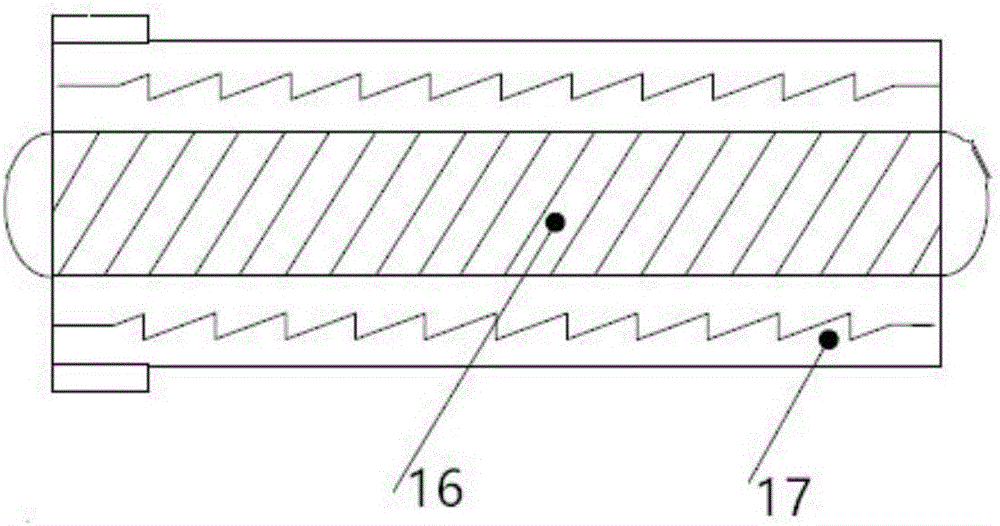

[0050] Such as figure 1 , figure 2 Shown is an energy-saving temperature swing adsorption system for separating carbon dioxide from industrial flue gas of the present invention. The system comprises: a first adsorption bed 1, a second adsorption bed 2 and a third adsorption bed 3, each adsorption bed has a heat exchange chamber 17 and an adsorption chamber 16 independent of each other, and the heat exchange chamber 17 heats the adsorption chamber 16 or cooling; and comprising: a hot flue gas supply pipeline 8 switchably communicated with each adsorption chamber 16 or heat exchange chamber 17, an air supply pipeline 10 switchably communicated with each heat exchange chamber 17, a switchably CO communicated with each adsorption chamber 16 2 Supply and recover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com