Three-dimensional dendritic conjugated compound-carbon nanotube composition, and preparation method and application

A technology of conjugated compounds and carbon nanotubes, which is applied in chemical instruments and methods, applications, chemical/physical processes, etc., can solve problems that have not been reported in any way, and achieve the effects of superior performance, less compound amount, and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0164] The invention also provides a preparation method of the composite ink. Wherein, the composite ink can adopt the following two preparation methods.

[0165] For example, the three-dimensional dendrimer conjugated compound is first dissolved in at least one solvent, and then the commercial large-diameter P2 single-walled carbon nanotubes are uniformly dispersed in the second The three-dimensional tree-shaped conjugated compound solution prepared in one step is finally subjected to short-term high-speed centrifugation, and the supernatant is separated to obtain an ink solution enriched in semiconductor-type large-diameter commercial carbon nanotubes.

[0166] For example, first mix the three-dimensional dendrimer conjugated compound with other organic semiconductor materials, and then dissolve them together in an organic solvent, and then disperse them evenly under the condition of temperature ≤ 0°C, and finally perform short-term high-speed centrifugation , separate the ...

Embodiment 1

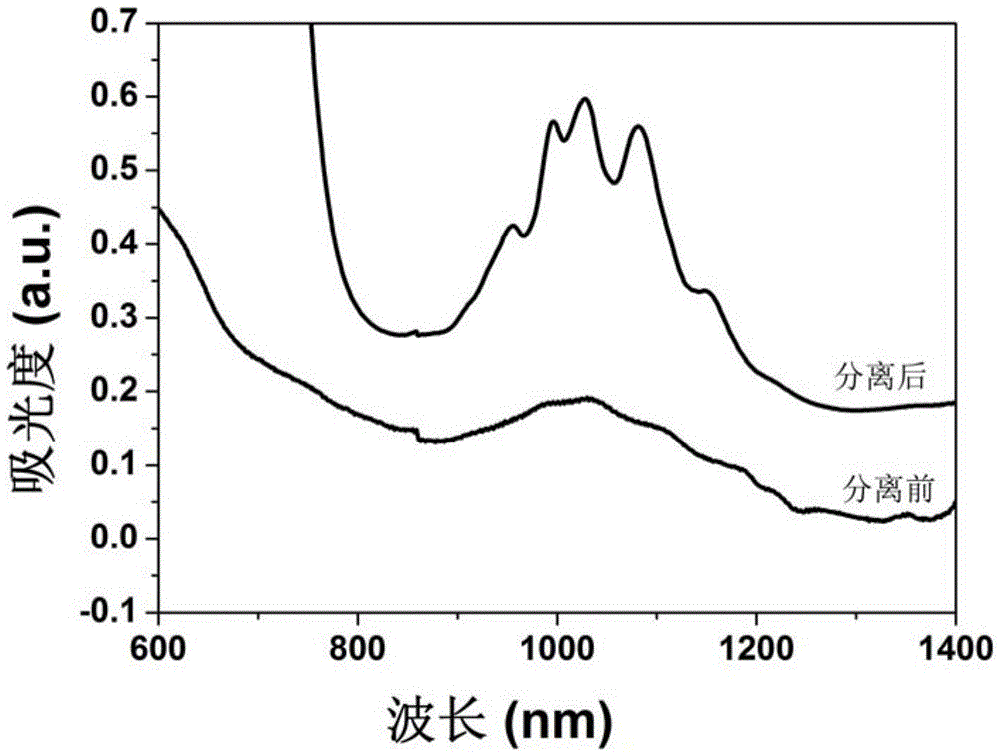

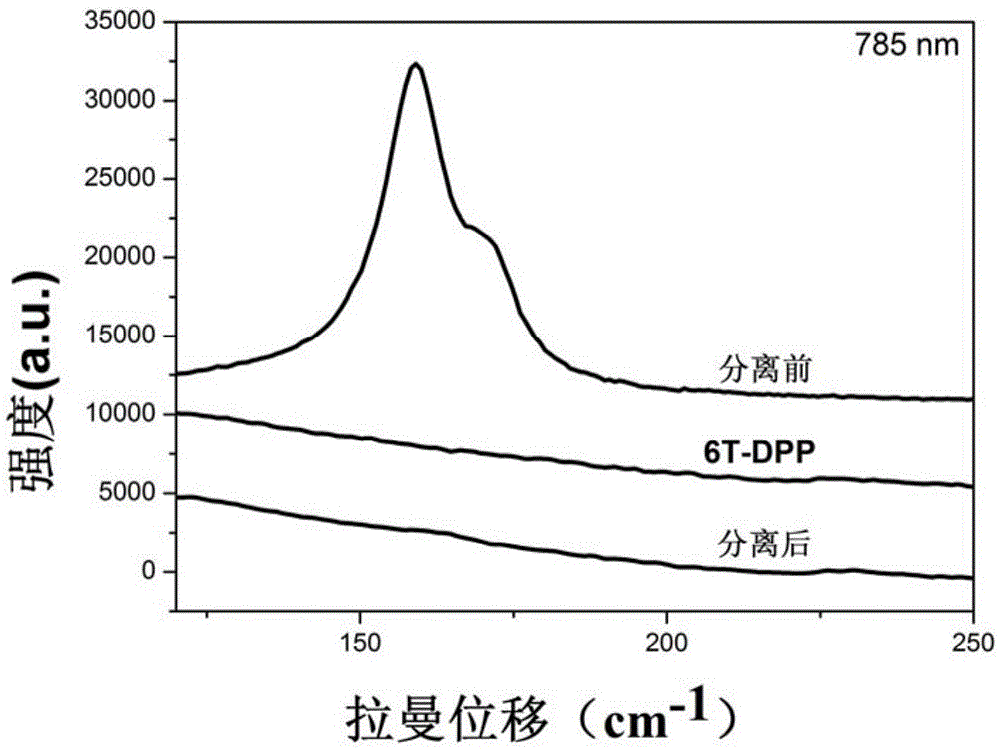

[0268] Example 1: Preparation of three-dimensional dendrimer conjugated compound (6T-DPP)-carbon nanotube composite ink

[0269] Weigh 2 mg of commercial large-diameter carbon nanotube P2 sample, dissolve it in 10 ml of toluene solution, then add 6 mg of a three-dimensional dendrimer conjugated compound 6T-DPP with a molecular weight of 4597, and use a power of 60 W in an ice bath The advanced ultrasonic cleaning machine ultrasonically disperses for 30 minutes, so that the polymer can selectively and fully interact with the semiconducting carbon nanotubes to obtain a uniformly dispersed dispersion. After being centrifuged at 15000rpm for 30 minutes, the carbon nanotube bundles in the above dispersion and the metallic carbon nanotubes not coated by the three-dimensional dendrimer conjugated compound are deposited on the bottom of the centrifuge tube, and the supernatant is separated to obtain a high Pure composite ink enriched with large-diameter semiconducting carbon nanotubes...

Embodiment 2

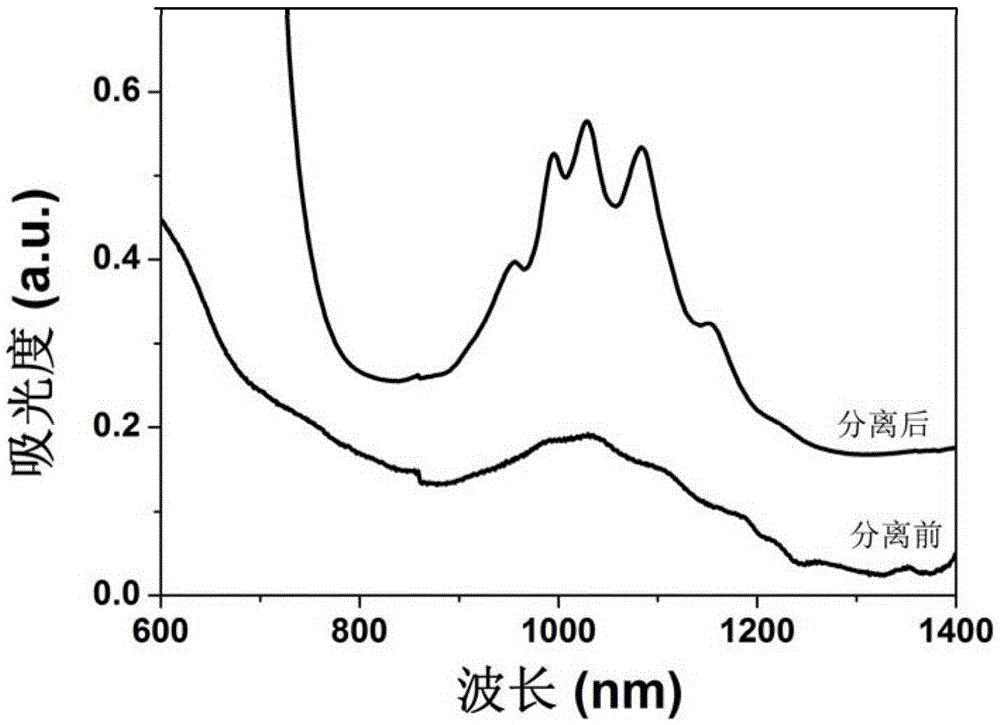

[0270]Example 2: Preparation of three-dimensional dendritic conjugated compound (9T-DPP)-carbon nanotube composite ink

[0271] Weigh 2 mg of commercial large-diameter carbon nanotube P2 sample, dissolve it in 10 ml of toluene solution, then add 6 mg of a three-dimensional dendrimer conjugated compound 9T-DPP with a molecular weight of 4848, and use a power of 60 W in an ice bath The advanced ultrasonic cleaning machine ultrasonically disperses for 30 minutes, so that the polymer can selectively and fully interact with the semiconducting carbon nanotubes to obtain a uniformly dispersed dispersion. After centrifugation at 15,000rpm for 30 minutes, the carbon nanotube bundles in the above dispersion and the metallic carbon nanotubes not covered by the three-dimensional dendrimer conjugated compound were deposited on the bottom of the centrifuge tube, and the supernatant was separated to obtain a high-purity Composite inks enriched with large-diameter semiconducting carbon nanotu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com