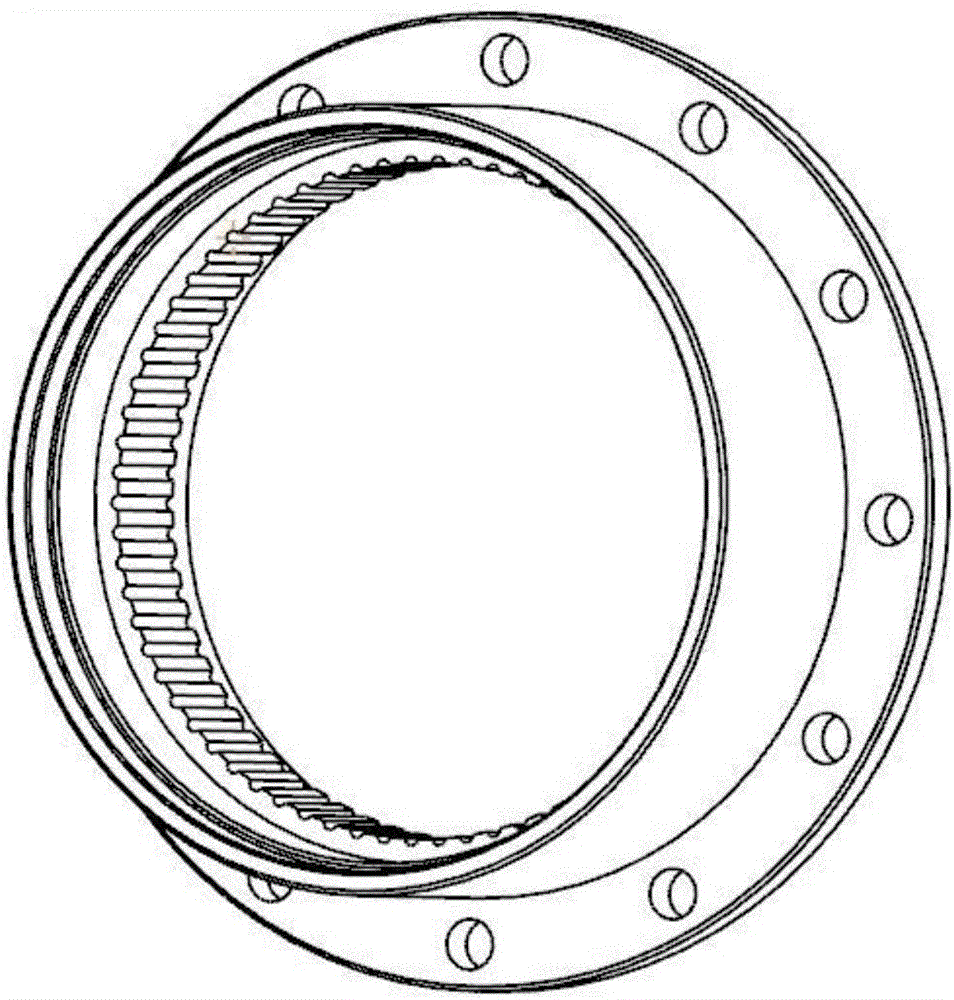

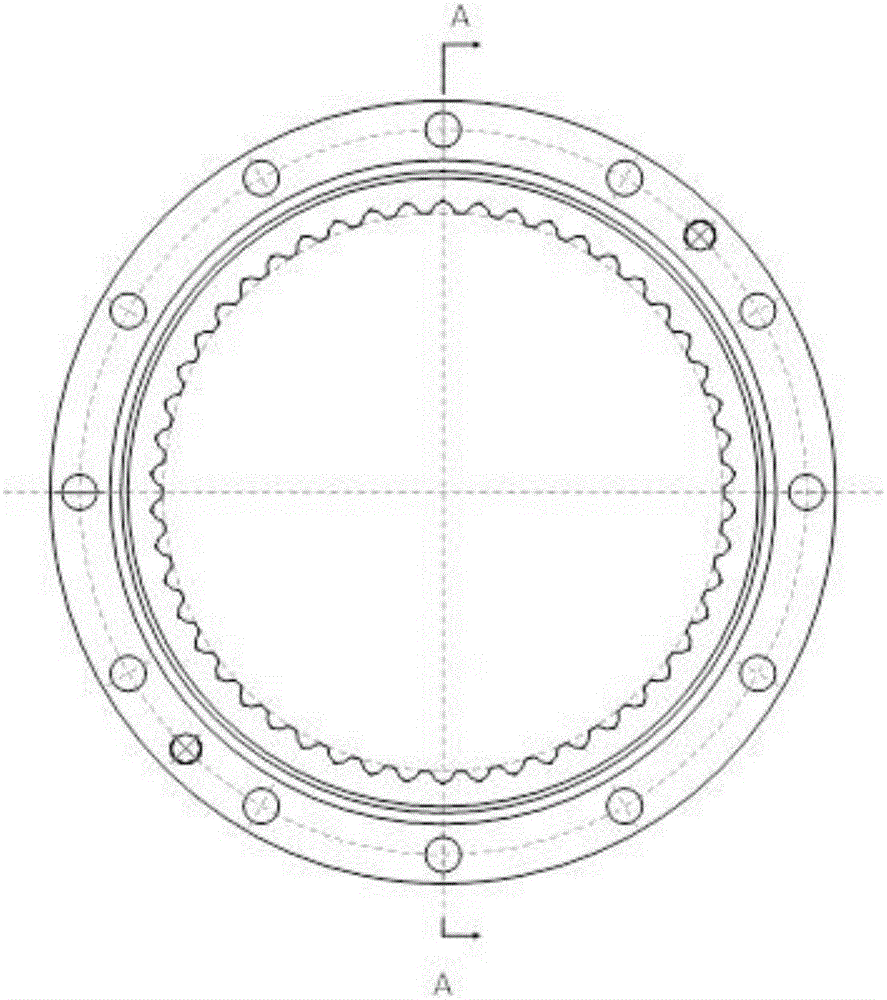

Machining technology for internal gear of precision planetary reducer with small tooth difference

A planetary reducer and processing technology, applied in the direction of belts/chains/gears, gear teeth, components with teeth, etc., can solve the problem of no research results reported on internal gears, reduce the cost of the whole machine, and improve the surface hardness , The effect of reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

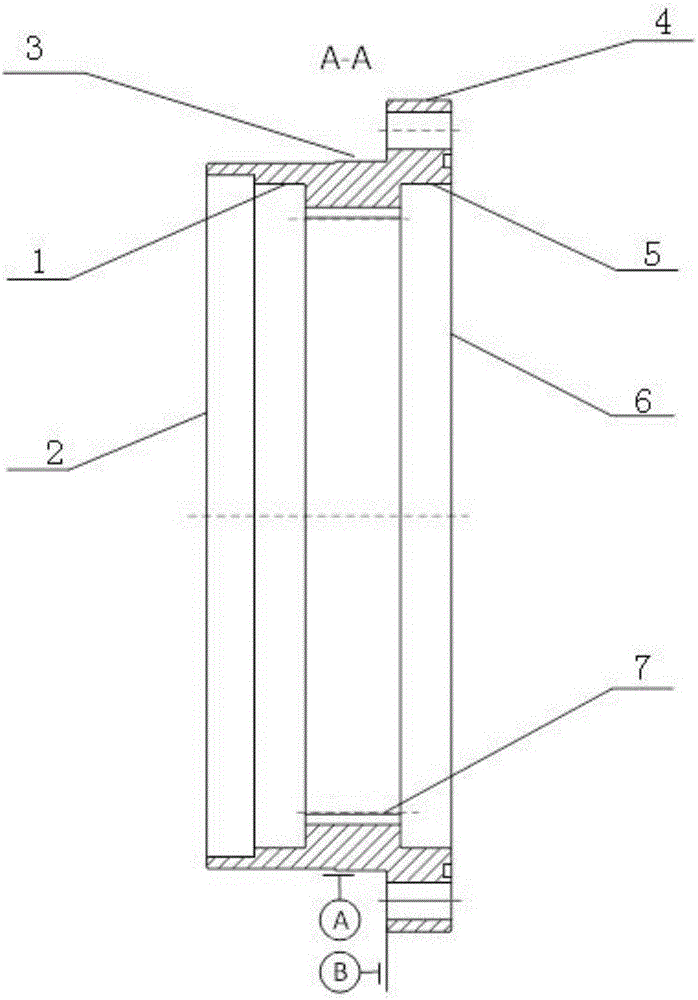

[0031] 1) Forging: The material is low-carbon high-quality alloy steel, and the blank is forged by die forging;

[0032] 2) Isothermal normalizing, the hardness of isothermal normalizing is HB160-190;

[0033] 3) Rough turning: the outer circle of the rough turning blank, the left and right end faces are flat, leaving a process allowance of 0.5mm to ensure the processing size; Axis, perpendicularity to the end face;

[0034] 4) Shaping: Based on the bearing raceway 5, use a special slotting tool to process the arc-shaped containment groove 7 of the internal gear, leaving a margin of 0.5mm;

[0035] 5) Heat treatment: Carburize and quench the raceways 1 and 5 and the inner gear arc containment groove 7, the depth of the carburized layer is 1-1.2mm, the surface hardness is HRC58-62, and the rest of the parts are treated with anti-seepage;

[0036] 6) Coarse grinding: with A as the reference, coarsely grind the right end face 6, the outer circle 4 and the bearing raceway 5 to e...

Embodiment 2

[0043] 1) Forging: The material is high-strength medium carbon steel, and the blank is forged by die forging;

[0044] 2) Isothermal normalizing, the hardness of isothermal normalizing is HB160-190;

[0045] 3) Rough turning: the outer circle of the rough turning blank, the left and right end faces are flat, leaving a process allowance of 0.5mm to ensure the processing size; Axis, perpendicularity to the end face;

[0046] 4) Shaping: Based on the raceway 5, use a special slotting tool to process the arc-shaped containment groove 7 of the internal gear, leaving a margin of 0.5mm;

[0047] 5) Heat treatment: local high-frequency quenching treatment for raceways 1, 5 and inner gear arc containment groove 7;

[0048] 6) Coarse grinding: with A as the reference, coarsely grind the right end face 6, the outer circle 4 and the bearing raceway 5 to ensure the coaxiality between the outer circle 4 and the bearing raceway 5, and the perpendicularity between the end face 6 and the bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com