Method for producing feed-grade calcium hydrophosphate from high-silica phosphorite

A technology of calcium hydrogen phosphate and high silicon phosphate rock, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of increasing product production costs, increasing raw material consumption, and high fluorine impurities, and achieving increased production costs, The method is simple and the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

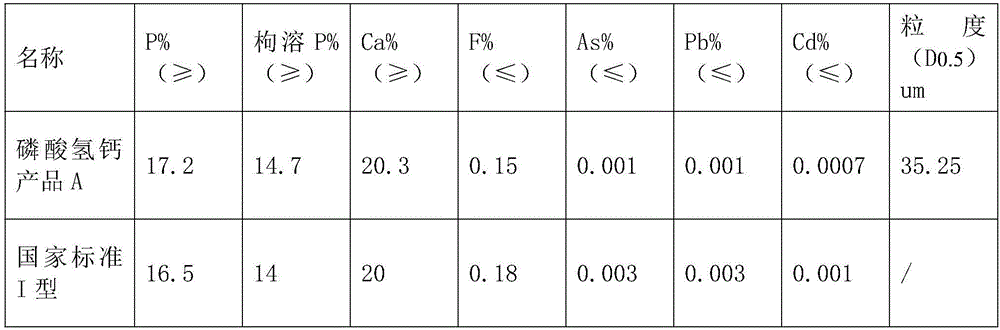

Embodiment 1

[0037] Produce feed grade calcium hydrogen phosphate product A with low-grade phosphate rock according to the following method:

[0038] (1) Take phosphate rock (P 2 o 5 =24.23%, SiO 2 =13.21%, MgO=1.5%), after pre-crushing, add it to the ball mill to crush and grind until the passing rate of 100 mesh sieve is greater than 80%, the qualified pulp is added to the extraction tank, add 98 acid, control the rate of 98 acid addition to maintain the extraction tank slurry The temperature is 85°C. After fully reacting, filter to obtain wet-process phosphoric acid.

[0039] (2) Add wet-process phosphoric acid into a neutralization tank, start stirring, and slowly add calcium carbonate to the above-mentioned wet-process phosphoric acid to carry out acid-base neutralization reaction. Slurry.

[0040] (3) Press filter the slurry after the primary neutralization, the filter residue is used for the production of fertilizer grade calcium hydrogen phosphate, and the primary filtrate ente...

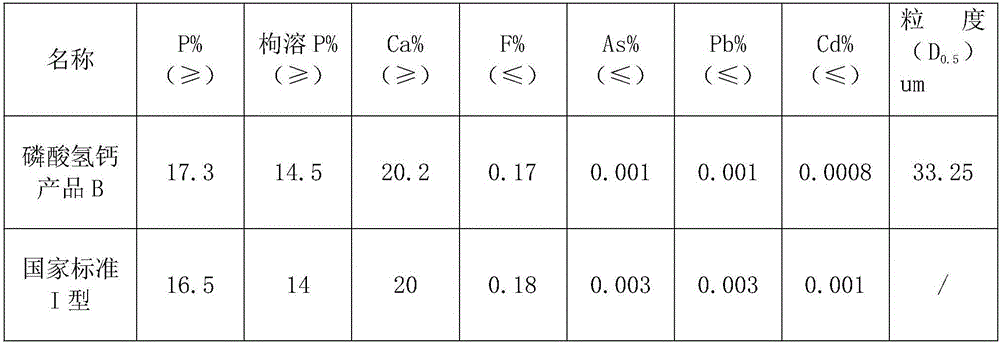

Embodiment 2

[0048] Produce feed grade calcium hydrogen phosphate product B with low-grade phosphate rock according to the following method:

[0049] (1) Take phosphate rock (P 2 o 5 =24.23%, SiO 2 =13.21%, MgO=1.5%), after pre-crushing, add it to the ball mill to crush and grind until the passing rate of 100 mesh sieve is greater than 80%, the qualified pulp is added to the extraction tank, add 98 acid, control the rate of 98 acid addition to maintain the extraction tank slurry The temperature is 85°C. After fully reacting, filter to obtain wet-process phosphoric acid.

[0050] (2) Add wet-process phosphoric acid into a first-stage neutralization tank, start stirring, and slowly add calcium carbonate to the above-mentioned wet-process phosphoric acid to carry out acid-base neutralization reaction, the pH of the reaction end point is 2.0, and a slurry after primary neutralization is obtained.

[0051] (3) Press filter the slurry after the primary neutralization, the filter residue is us...

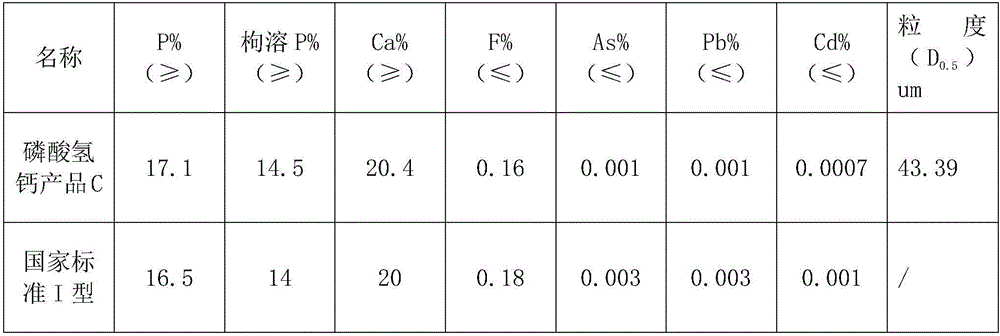

Embodiment 3

[0059] Produce feed grade calcium hydrogen phosphate product C with low-grade phosphate rock according to the following methods:

[0060] (1) Take phosphate rock (P 2 o 5 =24.23%, SiO 2 =13.21%, MgO=1.5%), after pre-crushing, add it to the ball mill to crush and grind until the passing rate of 100 mesh sieve is greater than 80%, the qualified pulp is added to the extraction tank, add 98 acid, control the rate of 98 acid addition to maintain the extraction tank slurry The temperature is 85°C. After fully reacting, filter to obtain wet-process phosphoric acid.

[0061] (2) Add wet-process phosphoric acid into a neutralization tank, start stirring, slowly add calcium carbonate to the above-mentioned wet-process phosphoric acid to carry out acid-base neutralization reaction, and start heating at the same time to raise the temperature to 50°C, and the reaction end point pH=2.0. Insulate for 30 minutes, and keep stirring during the insulated period to obtain a neutralized slurry....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com