Graphene surface modification method based on dry method

A graphene surface and graphene technology, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of high cost, expensive target materials and magnetron sputtering equipment, etc., achieve less product loss and increase load Transfer effects, effects that require less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Step 1: 1.5g graphene oxide is dissolved in 65% concentrated nitric acid in 50ml mass fraction

[0034] Ultrasonic dispersion with an ultrasonic power of 100W in the liquid for 1h, the mixture was centrifugally filtered, and the filter cake

[0035] Repeatedly washing with deionized water until neutral, and then drying in a vacuum oven at 60°C for 20 hours to obtain roughened graphene oxide for use;

[0036] Step 2: Take 1.0 g of the roughened graphene oxide in step 1 and place it on the planet

[0037] In the type ball mill, the set speed is 150r / min, the ball feeding ratio is 100:1, and the ball mill is 1h.

[0038] After the ball milling was stopped, 6.185g of silver acetate was poured into the ball mill and mixed with graphene oxide.

[0039] Secondary ball milling 1h, obtains the mixture of graphene oxide / silver acetate, for subsequent use;

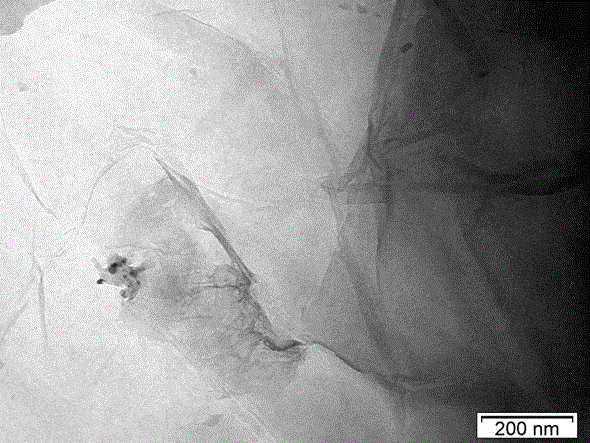

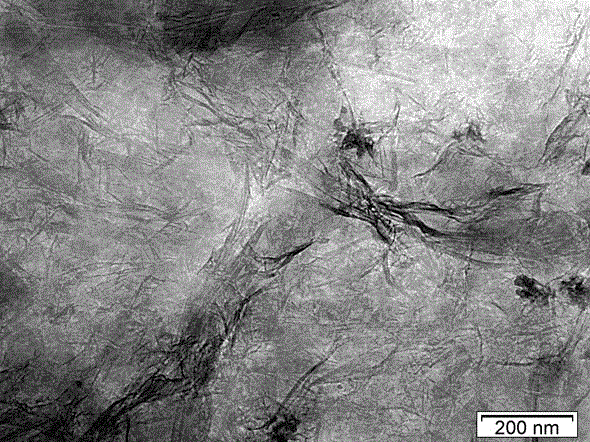

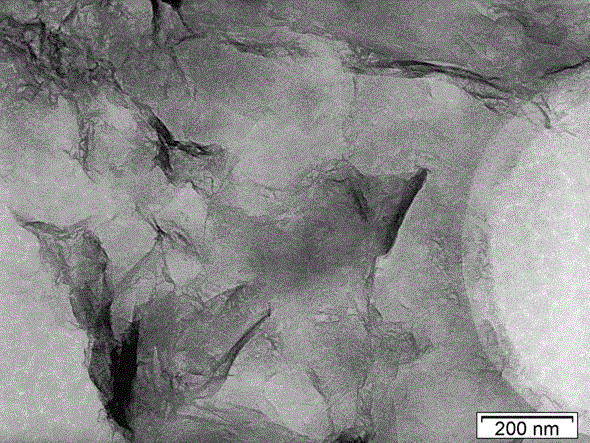

[0040] Figure 1-3 It is the permeability of graphene oxide in untreated, step one and step two in embodiment 1

[0041...

Embodiment 2

[0050] Step 1: 1.5g graphene oxide is dissolved in 65% concentrated nitric acid in 50ml mass fraction

[0051] Ultrasonic dispersion with an ultrasonic power of 100W in the liquid for 2h, the mixture was centrifugally filtered, and the filter cake

[0052] Repeatedly washing with deionized water to neutrality, and then drying in a vacuum oven at 60°C for 24 hours to obtain roughened graphene oxide for later use;

[0053] Step 2: Take 1.0 g of graphene oxide roughened in step 1 and place it in a planetary

[0054] In the ball mill, set the rotating speed to 250r / min, the ratio of ball feeding to 100:1, ball mill for 8 hours, and then

[0055] Stop the ball mill, pour 6.185g of silver acetate into the ball mill and mix it with graphene oxide again

[0056] Ball milling 2h, obtains the mixture of graphene oxide / silver acetate, standby;

[0057] Step 3: Put the graphene oxide / silver acetate mixture in step 2 in a muffle furnace, set the heating temperature to 300°C, and pass th...

Embodiment 3

[0060] Step 1: 1.5g graphene oxide is dissolved in 65% concentrated nitric acid in 50ml mass fraction

[0061] Ultrasonic dispersion with an ultrasonic power of 100W in the liquid for 3h, the mixture was centrifugally filtered, and the filter cake

[0062] Repeatedly washing with deionized water to neutrality, and then drying in a vacuum oven at 60°C for 28 hours to obtain roughened graphene oxide for future use;

[0063] Step 2: Take 1.0 g of graphene oxide roughened in step 1 and place it in a planetary

[0064] In the ball mill, set the rotating speed to 350r / min, the ball feeding ratio to 100:1, and ball mill for 13 hours.

[0065] After the ball milling was stopped, 6.185g of silver acetate was poured into the ball mill and mixed with graphene oxide.

[0066] Secondary ball milling 3h, obtains the mixture of graphene oxide / silver acetate, standby;

[0067] Step 3: Put the graphene oxide / silver acetate mixture in step 2 in a muffle furnace, set the heating temperature t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com