Anhydrous stemming and preparation method of anhydrous stemming

A technology of anhydrous taphole mud and high alumina, which is applied in the field of metallurgical refractory materials, can solve the problems of not being able to guarantee high-yield blast furnace tapping, low market acceptance, and failure to achieve environmental protection, so as to improve resistance to high-temperature melt penetration properties, inhibit mutual penetration and erosion, and reduce friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

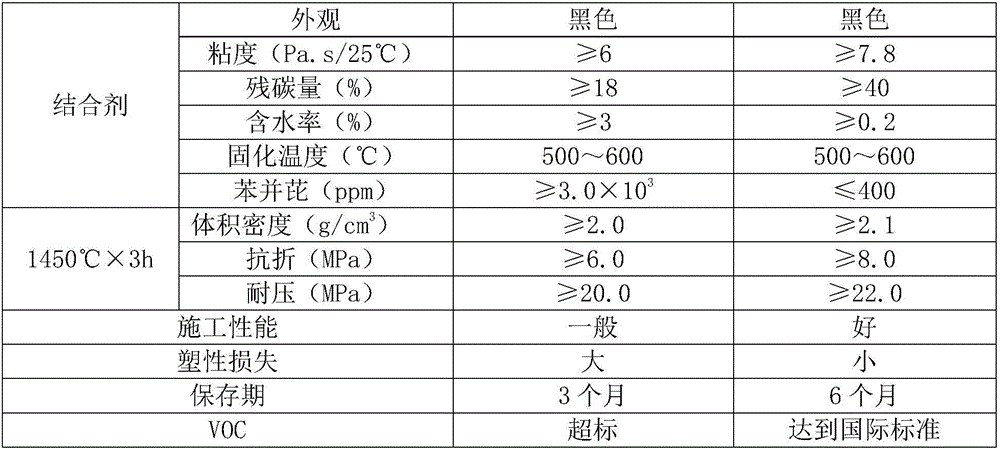

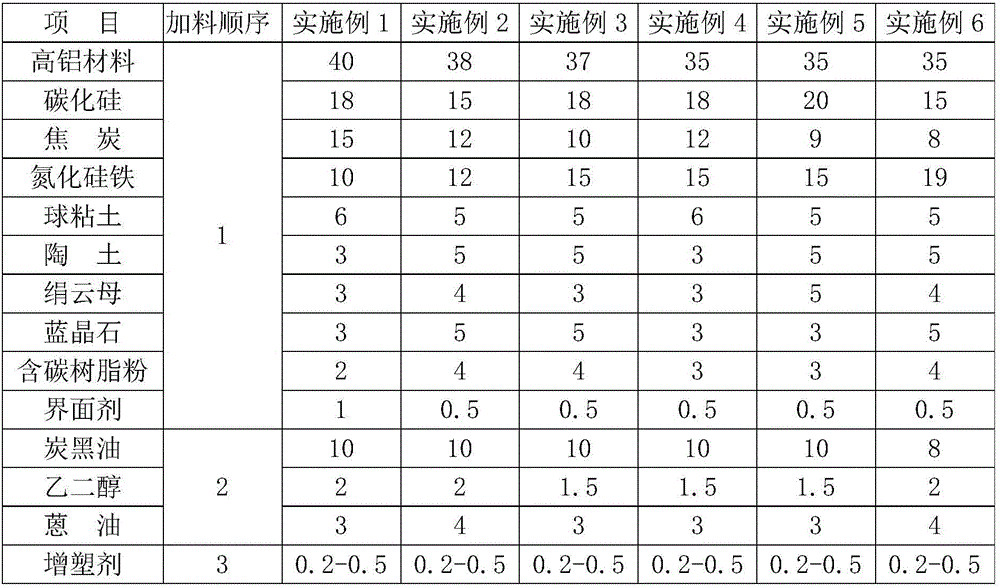

[0044] Table 2 lists the raw materials and their contents in parts by weight of each embodiment of the environment-friendly anhydrous taphole mud for blast furnace taphole of the present invention.

[0045] Table 2 each embodiment

[0046]

[0047] The manufacturing method of each embodiment is identical, and its manufacturing method is as follows:

[0048] ① Premix carbon black oil, ethylene glycol and anthracene oil according to the design ratio in Table 2 to form a mixed oil, and set aside;

[0049] ②Weigh various refractory raw materials according to the measurement ratio of parts by mass, mix them evenly and put them into bags for later use;

[0050] ③In order, first pour the mixed bulk materials into the test mixer and mix for 2 to 3 minutes, and then mix them evenly; After wetting the bulk material evenly; add plasticizer according to the design ratio in Table 2 to adjust the plasticity of the clay; measure the Masha value with the Masha instrument, and the Masha v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com