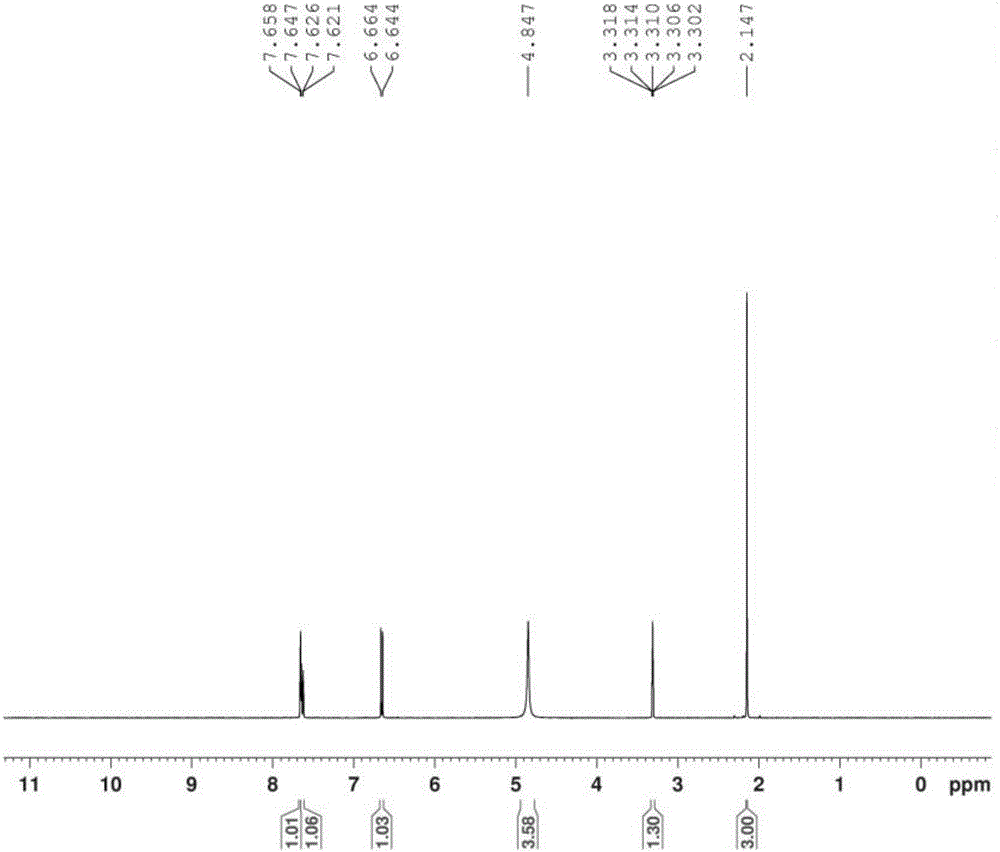

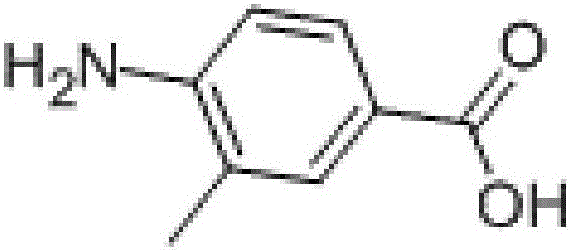

Preparation method of 3-methyl-4-aminobenzoic acid

A technology of aminobenzoic acid and nitrobenzoic acid, which is applied to the preparation of organic compounds, chemical instruments and methods, and cyanide reaction preparation, can solve the problems of complex operation, many by-products, and high cost, and achieve simple operation and improved The effect of product yield and product cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In the reaction flask equipped with reflux condenser, thermometer and stirrer, add 36.0 grams (0.2mol) of 3-methyl-4-nitrobenzoic acid, 0.3 grams (0.0009mol) of tetrabutylammonium bromide, and 300 Mix 1 ml of water evenly, then add 16.8 g (0.3 mol) of reduced iron powder, 3.0 g (0.056 mol) of ammonium chloride, 2 ml of concentrated hydrochloric acid, heat to 85°C under stirring, and react under reflux for 6 hours until the raw material 3- The reaction of methyl-4-nitrobenzoic acid is complete;

[0037] Cool down to 5°C, add sodium carbonate and activated carbon for decolorization for 0.5 hours, the addition of sodium carbonate and activated carbon is respectively 1.5% of the mass of 3-methyl-4-nitrobenzoic acid, adjust the pH value to be alkaline, filter the iron sludge, Wash twice with 5% sodium carbonate solution, mix and filter the mother liquor and cleaning solution to obtain a light yellow solution;

[0038] Add sulfuric acid to the above light yellow solution, ad...

Embodiment 2

[0042]In the reaction flask equipped with reflux condenser, thermometer and stirrer, add 36.0 grams (0.2mol) of 3-methyl-4-nitrobenzoic acid, 0.9 grams (0.0028mol) of tetrabutylammonium bromide and 300 milliliters Stir the water evenly, then add 16.8 g (0.3 mol) of reduced iron powder, 3.0 g (0.056 mol) of ammonium chloride, and 2 ml of concentrated hydrochloric acid, heat to 110°C under stirring, and react under reflux for 2 hours until the raw material 3-formazol Base-4-nitrobenzoic acid reacts completely;

[0043] Cool down to 35°C, add sodium carbonate and activated carbon for decolorization for 0.5 hour, the amount of sodium carbonate and activated carbon added is 1.5% of the mass of 3-methyl-4-nitrobenzoic acid respectively, and the pH value is adjusted to be alkaline. Filter the iron sludge, wash twice with 5% sodium carbonate solution, mix and filter the mother liquor and cleaning solution to obtain a light yellow solution;

[0044] Add sulfuric acid to the above ligh...

Embodiment 3

[0047] In the reaction flask equipped with reflux condenser, thermometer and stirrer, add 36.0 grams (0.2mol) of 3-methyl-4-nitrobenzoic acid, 0.3 grams (0.0009mol) of tetrabutylammonium bromide, and 150 Mix 1 ml of water evenly, then add 16.8 g (0.3 mol) of iron powder, 3.0 g (0.056 mol) of ammonium chloride, and 1 ml of concentrated hydrochloric acid, heat to 95°C under stirring, and react under reflux for 2.5 hours until the raw material 3-formazol Base-4-nitrobenzoic acid reacts completely;

[0048] Cool down to 10°C, add sodium carbonate and activated carbon for decolorization for 0.5 hour, the addition of sodium carbonate and activated carbon is respectively 1.5% of the mass of 3-methyl-4-nitrobenzoic acid, adjust the pH value to be alkaline, filter the iron sludge, Wash twice with 5% sodium carbonate solution, mix and filter the mother liquor and cleaning solution to obtain a light yellow solution.

[0049] Add sulfuric acid to the above light yellow solution, adjust t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com