Amphoteric tertiary amide type asphalt emulsifier and preparation method thereof

A technology of asphalt emulsifier and tertiary amide type, which is applied in the field of amphoteric tertiary amide type asphalt emulsifier and its preparation, which can solve the problems that are difficult to meet the application of crushed stone seal layer, and achieve convenient mixing and uniformity, increase hydrophilicity, and convenient metering The effect of feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] In one embodiment of the present application, the present invention provides the preparation method of above-mentioned amphoteric tertiary amide type asphalt emulsifier, comprising the following steps:

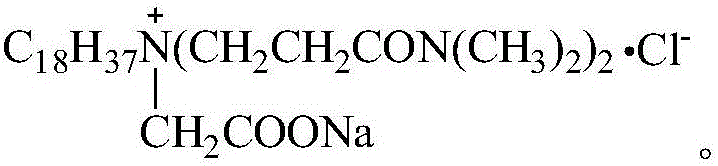

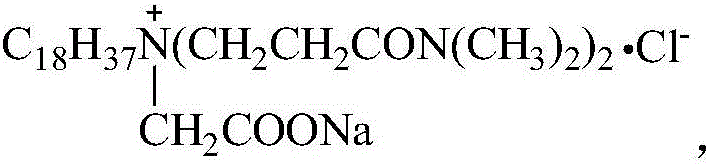

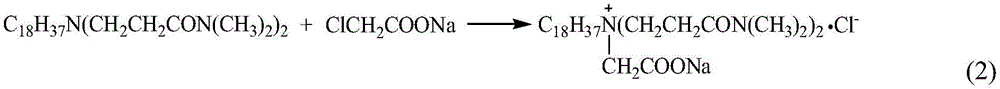

[0052] (1) Add octadecylamine into the reaction vessel, add alcohol solvent, heat and stir to dissolve, then add N,N-dimethylacrylamide in batches, after the addition, stir and react at 60-80°C for 2-4h , to obtain reaction intermediate I; the molecular formula of reaction intermediate I is C 18 h 37 N(CH 2 CH 2 CON(CH 3 ) 2 ) 2 .

[0053] (2) Add 28-38% (mass fraction) aqueous solution of sodium chloroacetate to the reaction intermediate I in batches, and react at 60-80° C. for 2-7 hours to obtain an amphoteric tertiary amide type asphalt emulsifier.

[0054] As a preferred embodiment, the molar ratio of octadecylamine, alcohol solvent, N,N-dimethylacrylamide, and sodium chloroacetate is 1mol: (4.00-9.00)mol: (2.00-2.10)mol: (1.02- 1.10) mol.

[0055] After a ...

Embodiment 1

[0065] (1) Preparation of amphoteric tertiary amide type asphalt emulsifier:

[0066] 1) Add 269.5g octadecylamine, 260g isopropanol in the reactor, heat and stir to dissolve. Then, 203.2 g of N,N-dimethylacrylamide was gradually added, and the reaction was stirred at 70°C for 3 h.

[0067] The above synthetic intermediate product was separated and purified by recrystallization and then detected by FTIR. The results are as follows: 2910cm -1 It is the asymmetric stretching vibration absorption peak of methylene, 2840cm -1 Closed peak for the symmetrical stretching vibration of methylene, 1650cm -1 and 1625cm -1 It is the C=O stretching vibration absorption peak in the amide group, 1460cm -1 is the asymmetric bending vibration of methylene, 1390cm -1 is the asymmetric bending vibration of the methyl group, 1263cm -1 and 1153cm -1 C-N stretching vibration absorption peak, 777cm -1 and 719cm -1 It is the in-plane rocking vibration absorption peak of methylene.

[0068] ...

Embodiment 2

[0078] (1) Preparation of amphoteric tertiary amide type asphalt emulsifier:

[0079] 1) Add 269.5g octadecylamine and 260g absolute ethanol in the reactor, heat and stir to dissolve. Then, 203.2 g of N,N-dimethylacrylamide was gradually added, and the reaction was stirred at 70°C for 3 h.

[0080] 2) Dissolve 42.4g of sodium hydroxide in 80.0g of water to obtain an aqueous solution of sodium hydroxide, dissolve 100.2g of chloroacetic acid in 200.0g of water to obtain an aqueous solution of chloroacetic acid; add the aqueous solution of sodium hydroxide dropwise to an aqueous solution of chloroacetic acid to obtain an aqueous solution of sodium chloroacetate . The prepared sodium chloroacetate aqueous solution was added dropwise to the product synthesized in step 1) above, and stirred at 75° C. for 3 h. The obtained amphoteric tertiary amide type asphalt emulsifier was reserved for the emulsified asphalt test.

[0081] (2) Preparation of emulsified asphalt:

[0082] Take 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com