Polyester ether polyol preparation method

A technology of polyether ester polyol and polyester polyol, which is applied in the field of preparation of polyether ester polyol, can solve the problems of poor mechanical properties of polyurethane materials, complex catalyst post-treatment, catalyst residue, etc., and achieve simple and controllable adjustment, Easy-to-achieve, low-impact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

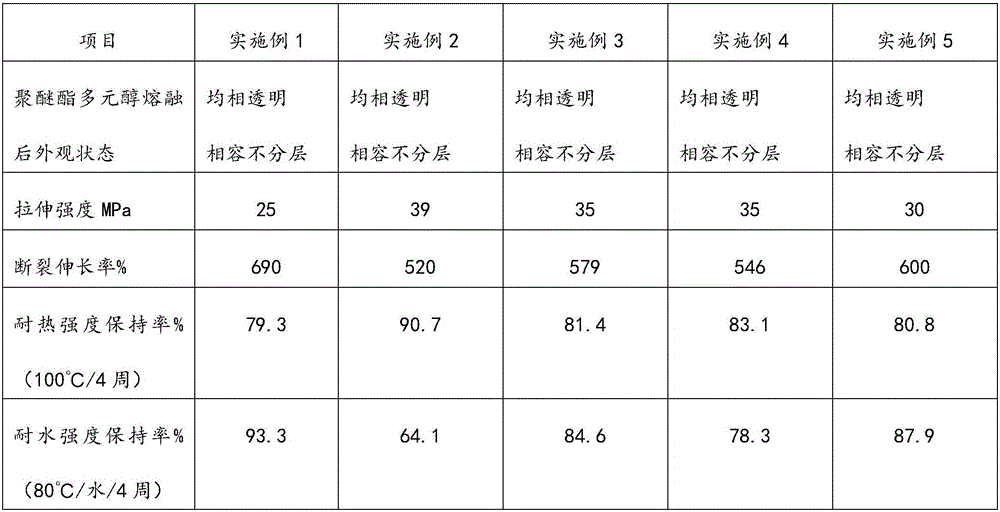

Examples

Embodiment 1

[0025] Add 5400g of polytetrahydrofuran glycol (PTMG-600) with a molecular weight of 600g / mol to the reaction kettle, heat up under nitrogen protection and start stirring, the temperature rises to 100°C and depressurizes for 1h, and the moisture in the polyether polyol is removed, and then Return to normal pressure and add 600g of polybutylene adipate diol with a molecular weight of 600g / mol, add catalyst tetraisopropyl titanate 0.12g, continue to heat up to 150°C, and vacuumize to -0.095 Mpa, transesterification reaction under reduced pressure for 2 hours; after the transesterification reaction, return to normal pressure and lower the temperature to 70°C, add 0.10g of dibutyl phosphate, and stir for 1 hour to obtain a polyether ester polyol product with no active catalyst residue, molecular weight It is 1500g / mol.

Embodiment 2

[0027] Add 600g of polyoxypropylene glycol (PPG-3000) with a molecular weight of 3000g / mol to the reaction kettle, raise the temperature under the protection of nitrogen and start stirring, the temperature rises to 100°C and the pressure is reduced for 1h, and the moisture in the polyether polyol is removed. Then return to normal pressure and add 5400g of polyethylene adipate butanediol with a molecular weight of 3000g / mol, add 0.05g of tetraisopropyl titanate as a catalyst, continue to heat up to 120°C, react under normal pressure for 1 hour and pump Vacuum to -0.09Mpa, transesterification reaction under reduced pressure for 10h; after the transesterification reaction, return to normal pressure and lower the temperature to 70°C, add 0.01g of dibutyl phosphate, stir for 1h, and obtain the polyether ester multi-component polyether ester with no active catalyst residue. Alcohol product, molecular weight is 1000g / mol.

Embodiment 3

[0029] Add 4000g of tetrahydrofuran with a molecular weight of 1000g / mol and propylene oxide copolymerized glycol into the reaction kettle, raise the temperature under the protection of nitrogen and start stirring, raise the temperature to 100°C and reduce the pressure for 1h, remove the moisture in the polyether polyol, and then restore Add 5400g of polybutylene succinate diol with a molecular weight of 1500g / mol under normal pressure, add 0.22g of tetraisopropyl titanate as a catalyst, continue to heat up to 200°C, and vacuumize to -0.096Mpa after reacting under normal pressure for 1 hour , transesterification reaction under reduced pressure for 4 hours; after the transesterification reaction, return to normal pressure and cool down to 70°C, add 0.06g of dibutyl phosphate, and stir for 1 hour to obtain a polyether ester polyol product with no active catalyst residue, the molecular weight is 2000g / mol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com