Method for solving dust pollution caused by pearlescent pigment applied to ABS coloring

A technology of pearlescent pigments and dust pollution, applied in the field of plastic coloring, to achieve the effects of enhancing pearlescent effect, avoiding pollution, and obvious cost advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

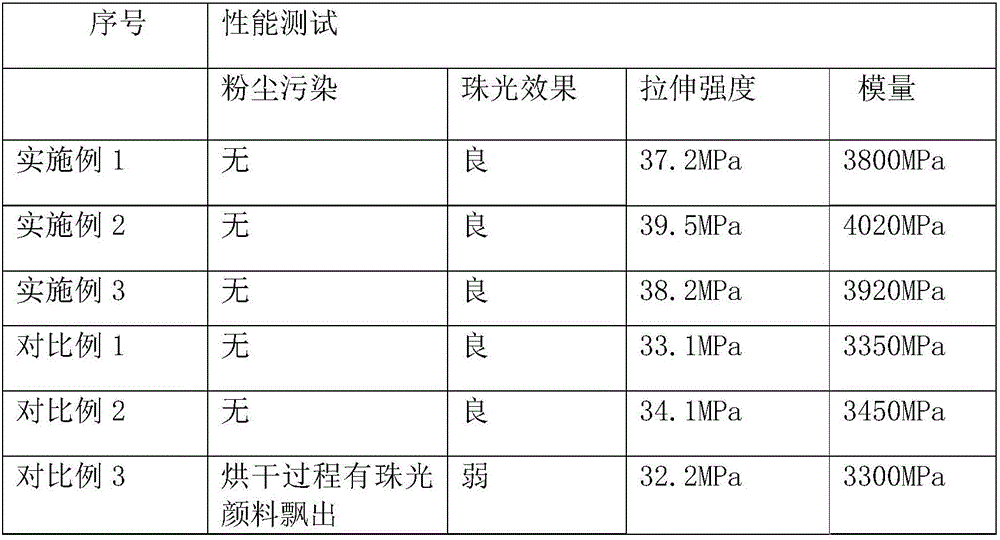

Examples

Embodiment 1

[0014] It is made of the following ingredients by weight: First, dissolve 5 parts of ABS resin in 85 parts of dichloromethane to make ABS polymer solution, add 5 parts of pearlescent pigment powder, 0.5 part of dicumyl peroxide under constant stirring , 2.5 parts of maleic anhydride, 1 part of antioxidant 1010, 1 part of antioxidant 168, after fully stirring evenly, a composite component paste with 5% relatively low viscosity of pearlescent pigment is obtained.

[0015] Mix the above-mentioned compound component paste with the ABS resin to be colored in a high-mixer at a weight ratio of 3 to 5 per thousand, and then dry it at 80 degrees Celsius for 4 hours, and then make injection molding samples preparation.

Embodiment 2

[0017] First, dissolve 10 parts of ABS resin in 75 parts of acetone solution to make ABS polymer solution, add 10 parts of pearlescent pigment powder, 0.5 parts of dicumyl peroxide, 2.5 parts of maleic anhydride, 1 part of anti Oxygen 330, 1 part of antioxidant 1084, after fully stirring evenly, a composite component paste of 10% pearlescent pigment with medium viscosity is obtained.

[0018] The added pearlescent pigment is that the surface of the flake substrate is coated with pigment, the substrate is mica sheet or glass sheet, the particle size of the substrate is 10um-80um, and the pigment is iron oxide or aluminum oxide. The ABS in the paste composite component body is selected from conventional pure resin, Chimei PA-707 or PA-747

[0019] Mix the above-mentioned compound component paste with the ABS resin to be colored in a high-mixer at a weight ratio of 3 to 5 per thousand, and then dry it at 80 degrees Celsius for 4 hours, and then make injection molding samples pre...

Embodiment 3

[0021] First, dissolve 10 parts of ABS resin in 70 parts of dimethylformamide to form an ABS polymer solution, add 15 parts of pearlescent pigment powder, 0.5 parts of dicumyl peroxide, 2.5 parts of maleic anhydride, 1 1 part of antioxidant 264, 1 part of antioxidant 1084, after fully stirring evenly, a composite component paste with 15% of pearlescent pigments and relatively high viscosity is obtained.

[0022] Mix the above-mentioned composite component paste with the ABS resin to be colored at a ratio of 3 to 5 per thousand in a high-mixer, and then dry it at 80 degrees Celsius for 4 hours before preparing injection molding samples.

[0023] The present invention is not limited to the combination of the above three embodiments, and the actual implementation can properly adjust the content of the pigment in the composite component according to the type and amount of the pigment added in order to achieve the best effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com