A kind of composite material for treating heavy metal pollution in soil and preparation method thereof

A technology of composite materials and heavy metals, applied in the field of environmental pollution control, to achieve the effects of improving removal efficiency, facilitating recycling, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

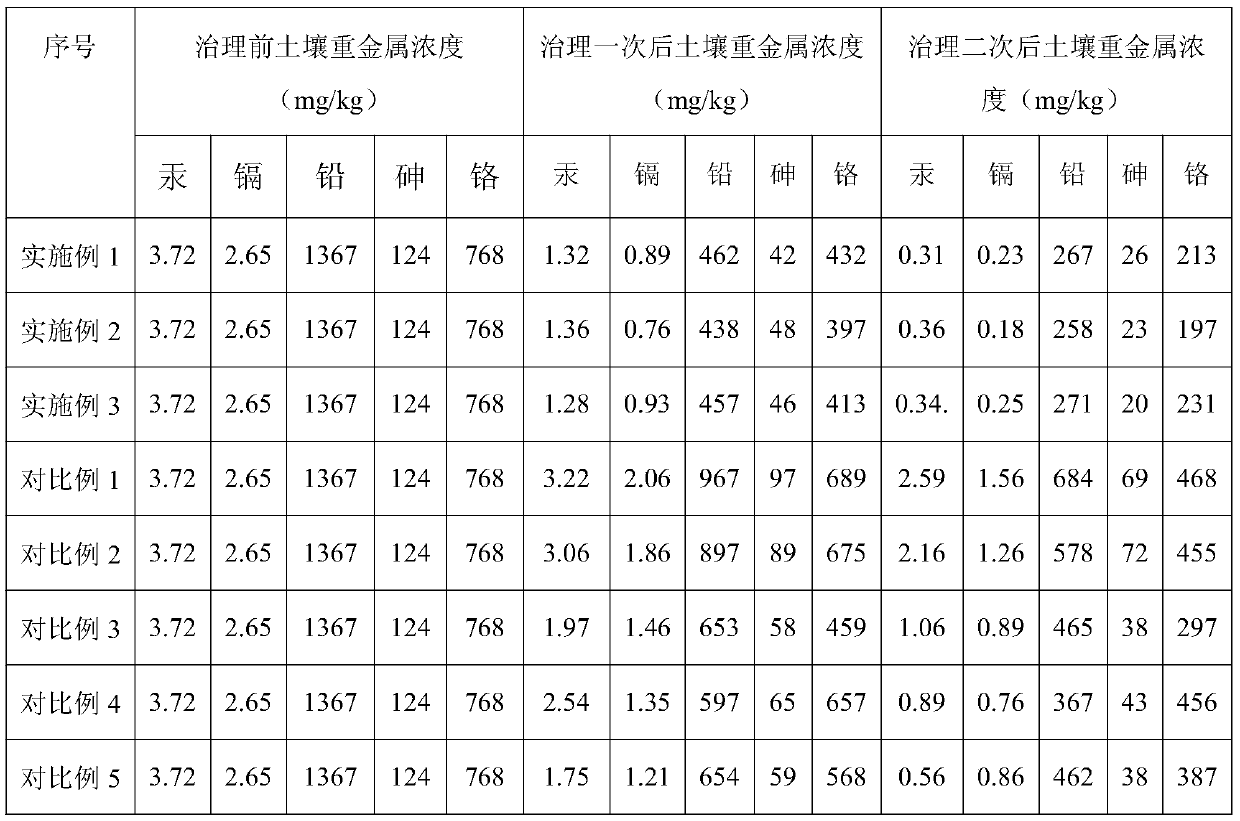

Examples

Embodiment 1

[0025] A composite material for controlling soil heavy metal pollution, prepared by the following preparation method:

[0026] 1. With 8 parts by weight of lignocellulose, 20 parts of hydroxy acid, 30 parts of polyvinyl alcohol, 15 parts of amorphous olefin copolymer, 4 parts of sodium citrate and 2 parts of sodium phosphate and sodium borate The amount ratio of the substance is 1:2, and the initiator is dissolved in the solvent mixed with the ratio of glycerin and water in the amount of 1:4. After mixing evenly, it is heated to 140°C for graft polymerization. React for 30 minutes to obtain a composite polymer material;

[0027] 2. Mix the composite polymer material obtained in step 1 with 15 parts of azodicarbonamide, 15 parts of sodium carbonate, and 0.8 part of dicumyl peroxide and place it in a mold for foaming, and use mechanical force to break the closed cells. A composite material with a porous sponge structure is obtained;

[0028] The composite material for controll...

Embodiment 2

[0030] A composite material for controlling soil heavy metal pollution, prepared by the following preparation method:

[0031] 1. With 5 parts by weight of lignocellulose, 30 parts of hydroxy acid, 20 parts of polyvinyl alcohol, 25 parts of amorphous olefin copolymer, 5 parts by weight of sodium citrate and 1 part of potassium phosphate and potassium borate The initiator mixed with the ratio of the substance amount of the substance is 1:5 is dissolved in the solvent mixed with the ratio of the substance amount of glycerol and water of 1:3, and after mixing evenly, it is heated to 130°C for graft polymerization React for 20 minutes to obtain a composite polymer material;

[0032] 2. Mix the composite polymer material obtained in step 1 with 20 parts of azodicarbonamide, 10 parts of sodium carbonate, and 0.5 part of dicumyl peroxide, place it in a mold for foaming, and use mechanical force to break the closed cells. A composite material with a porous sponge structure is obtaine...

Embodiment 3

[0035] A composite material for controlling soil heavy metal pollution, prepared by the following preparation method:

[0036] 1. 10 parts by weight of lignocellulose, 10 parts of hydroxy acid, 40 parts of polyvinyl alcohol, 10 parts of amorphous olefin copolymer, 3 parts of sodium citrate and 3 parts of ammonium phosphate and sodium borate The initiator mixed with the ratio of the substance amount of the substance is 1:1 is dissolved in the solvent mixed with the ratio of the substance amount of glycerin and water of 1:5, and after mixing evenly, it is heated to 150°C for graft polymerization React for 40 minutes to obtain a composite polymer material;

[0037] 2. Mix the composite polymer material obtained in step 1 with 10 parts of azodicarbonamide, 20 parts of sodium carbonate, and 1.0 part of dicumyl peroxide, place it in a mold for foaming, and use mechanical force to break the closed cells, A composite material with a porous sponge structure is obtained;

[0038] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com