Biomass pyrolysis polygeneration system

A technology of biomass pyrolysis and polygeneration, which is applied in the direction of biofuel, removal of gaseous pollutants, gas purification of condensed non-gaseous materials, etc., can solve the problems of low energy conversion and utilization rate, low technical content, small scale, etc. problems, to achieve the effect of comprehensive and effective utilization, wide applicability of technology, and reduction of lye consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

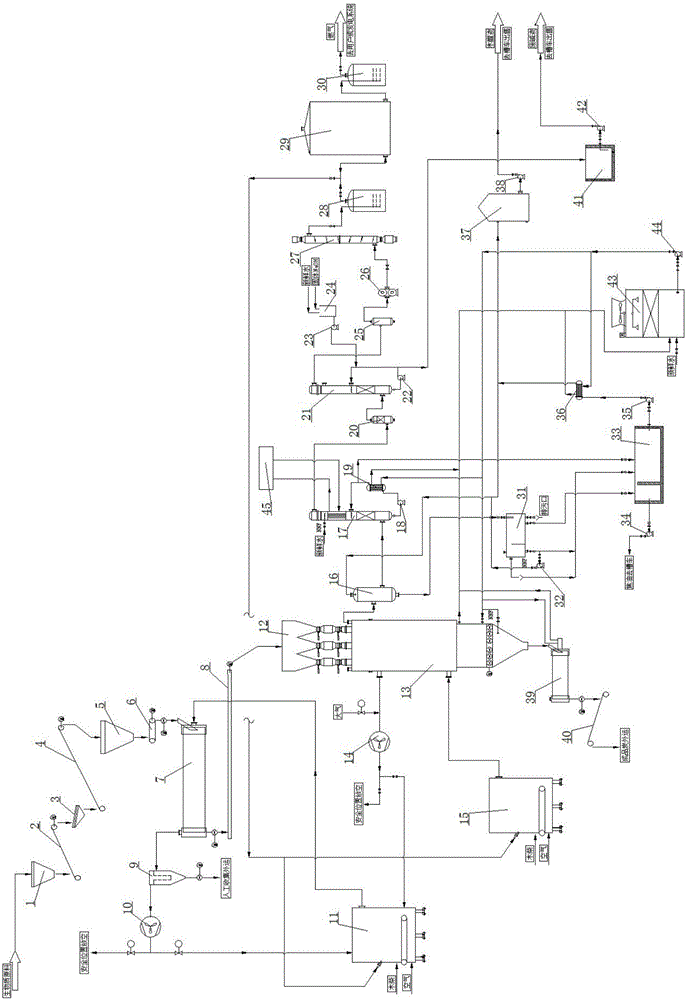

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0025] see figure 1 , a biomass pyrolysis polygeneration system, which uses biomass as raw material, undergoes biomass drying, biomass pyrolysis, pyrolysis gas purification, tar / wood vinegar liquid separation, finished carbon storage and transportation, gas cabinet 29 and Supporting public system to obtain biomass charcoal, biomass gas, biomass tar and vinegar liquid products; including raw material hopper 1, belt conveyor I2, raw material screening machine 3, belt conveyor II4, drying furnace feed bin 5, Weighing feeder 6, drying furnace 7, buried scraper conveyor 8, bag filter 9, drying hot blast furnace 11, pyrolysis feed bin 12, pyrolysis furnace 13, high temperature flue gas fan 14, pyrolysis hot air Furnace 15, pickling tank 16, water washing tower 17, water washing tower circulation pump 18, washing water cooler 19, water wash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com