Metal-modified superhydrophobic material and preparation method thereof

A metal modification and super-hydrophobic technology, applied in metal material coating process, liquid chemical plating, coating, etc., to achieve the effect of simple equipment, low cost, strong binding force and anti-corrosion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

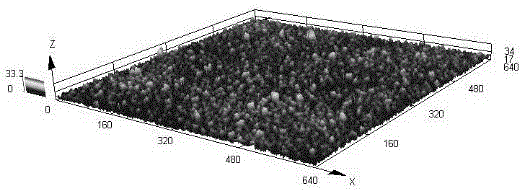

Image

Examples

Embodiment 1

[0046] The preparation method of the metal-modified superhydrophobic material of the present invention comprises the following steps:

[0047] (1) Using polylactic acid as a template, place the template in a sodium hydroxide solution with a concentration of 4M and immerse it for 10 minutes at a temperature of 40 °C, and etch holes on the template through the sodium hydroxide solution to obtain a template with holes ;

[0048] (2) Immerse the template with holes in a sensitizing solution mainly composed of 90 mg stannous chloride, 3.3 mL ethanol, 46 uL trifluoroacetic acid and 6.7 mL deionized water for 1 min to sensitize the template , to obtain a template adsorbed with divalent tin ions;

[0049] (3) Immerse the template adsorbed with divalent tin ions in an activation solution mainly composed of 218mg palladium chloride, 10mL deionized water and 47mg sodium chloride for 1min to activate the template, and then return the template to Adsorbed with divalent palladium ions to ...

Embodiment 2

[0061] The preparation method of the metal-modified superhydrophobic material of the present invention comprises the following steps:

[0062] (1) Using polylactic acid as a template, place the template in a sodium hydroxide solution with a concentration of 4M and immerse it for 10 minutes at a temperature of 40 °C, and etch holes on the template through the sodium hydroxide solution to obtain a template with holes ;

[0063] (2) Immerse the template with holes in a sensitizing solution mainly composed of 90 mg stannous chloride, 3.3 mL ethanol, 46 uL trifluoroacetic acid and 6.7 mL deionized water for 1 min to sensitize the template , to obtain a template adsorbed with divalent tin ions;

[0064] (3) Immerse the template adsorbed with divalent tin ions in an activation solution mainly composed of 218mg palladium chloride, 10mL deionized water and 47mg sodium chloride for 1min to activate the template, and then return the template to Adsorbed with divalent palladium ions to ...

Embodiment 3

[0076] The preparation method of the metal-modified superhydrophobic material of the present invention comprises the following steps:

[0077] (1) Using polylactic acid as a template, place the template in a sodium hydroxide solution with a concentration of 2M and immerse it for 20 minutes at a temperature of 50 °C, and etch holes on the template through the sodium hydroxide solution to obtain a template with holes;

[0078] (2) Immerse the template with holes in a sensitizing solution mainly composed of 90 mg stannous chloride, 3.3 mL ethanol, 46 uL trifluoroacetic acid and 6.7 mL deionized water for 1 min to sensitize the template , to obtain a template adsorbed with divalent tin ions;

[0079] (3) Immerse the template adsorbed with divalent tin ions in an activation solution mainly composed of 218mg palladium chloride, 10mL deionized water and 47mg sodium chloride for 1min to activate the template, and then return the template to Adsorbed with divalent palladium ions to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com