Gasoline engine for complete internal cooling hybrid electric automobile

A hybrid electric, gasoline engine technology, applied in engine components, machines/engines, mechanical equipment, etc., can solve the problems of good cooling effect, high thermal efficiency, low fuel consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Internal-combustion engine (gasoline engine) that the present invention refers refers to that oil is used as fuel to perform work in the cylinder combustion, with shaft power output. The law of thermodynamics points out that the thermal energy of any heat engine fuel can only do work by one-third, pass one-third to the cooling system, and pass one-third to the exhaust gas. The calorific value of gasoline is about 10,000 calories per kilogram, while the latent heat of evaporation of water is more than 800 calories per kilogram. In addition, heating from saturated steam to 4-500 degrees requires about 4-500 calories per kilogram. kg, so the amount of water required to achieve complete internal cooling of a gasoline engine is about 2 to 3 times the amount of fuel.

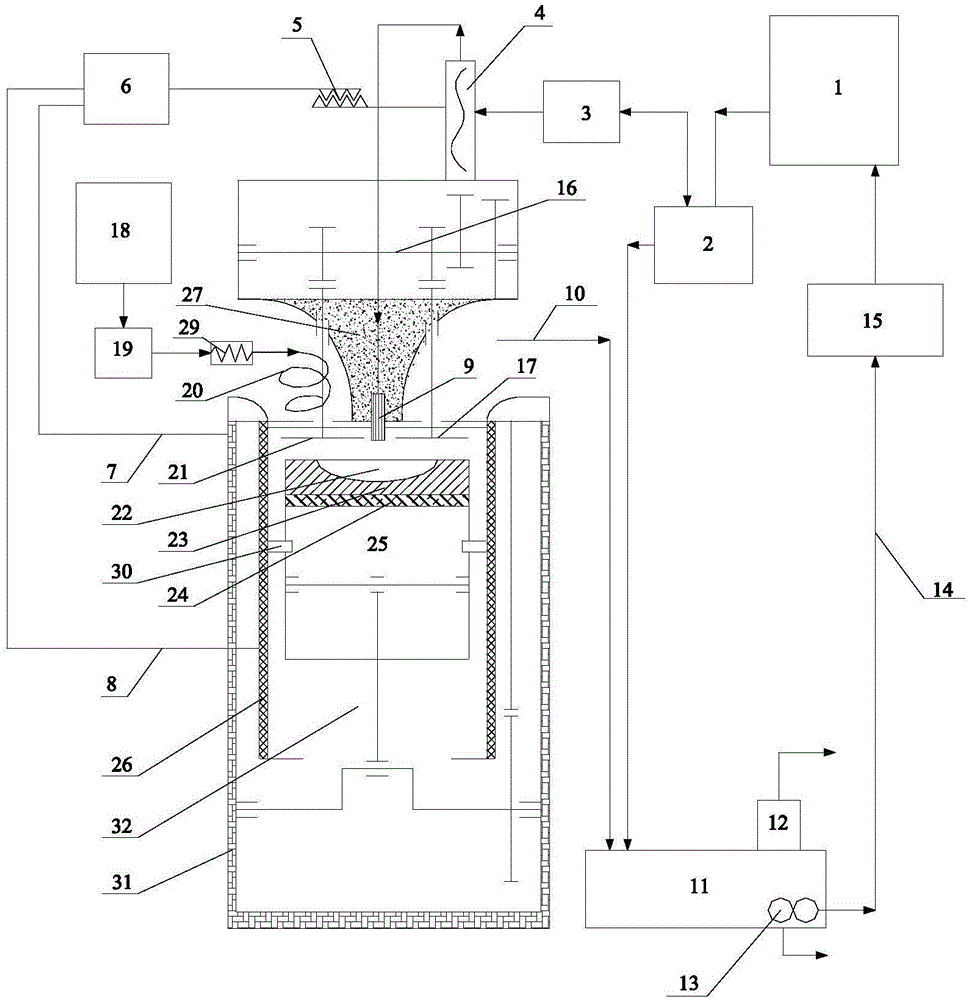

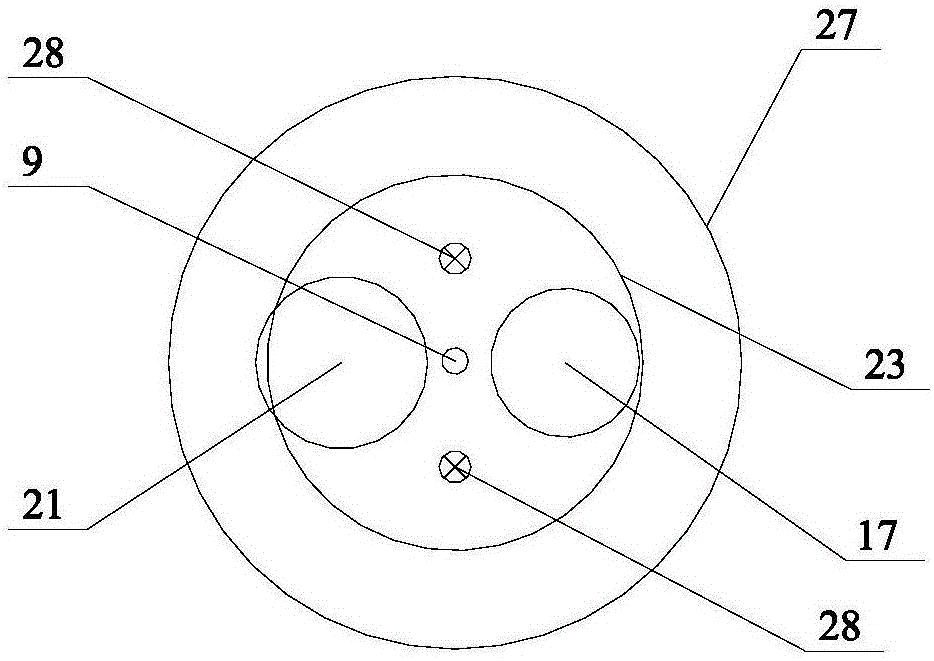

[0036] Such as figure 1 with figure 2 Shown, the gasoline engine of the present invention, its cooling system comprises the water injection system that contains pure water tank 3, water supply pump 4 and noz...

Embodiment 2

[0043] The law of thermodynamics also stipulates that the thermal efficiency of a heat engine depends on the maximum absolute value of the high-temperature heat source and the difference between the temperature of the low-temperature cold source. The higher these two values are, the higher the thermal efficiency is. The present invention has successfully reduced the temperature of the end of expansion and exhaust by spraying water in the engine, and if the same high-temperature heat source temperature as that of the ordinary internal combustion engine is obtained, the thermal efficiency of the engine must be higher than that of the ordinary gasoline engine. The temperature of the high-temperature heat source is determined by the intake combustion system of the gasoline engine of the present invention.

[0044] Such as figure 1 with figure 2 As shown, the intake air of the gasoline engine is delivered by the oil tank 18 and mixed with the incoming air through the carburetor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com