Device for testing normal spectral emissivities of infrared transparent materials

A technology of spectral emissivity and transparent materials, which is applied in the field of infrared transparent material normal spectral emissivity testing devices, can solve the problems of easy cracking of samples, poor measurement result accuracy, single testable materials, etc., to achieve accurate measurement and ensure accurate measurement , the effect of uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

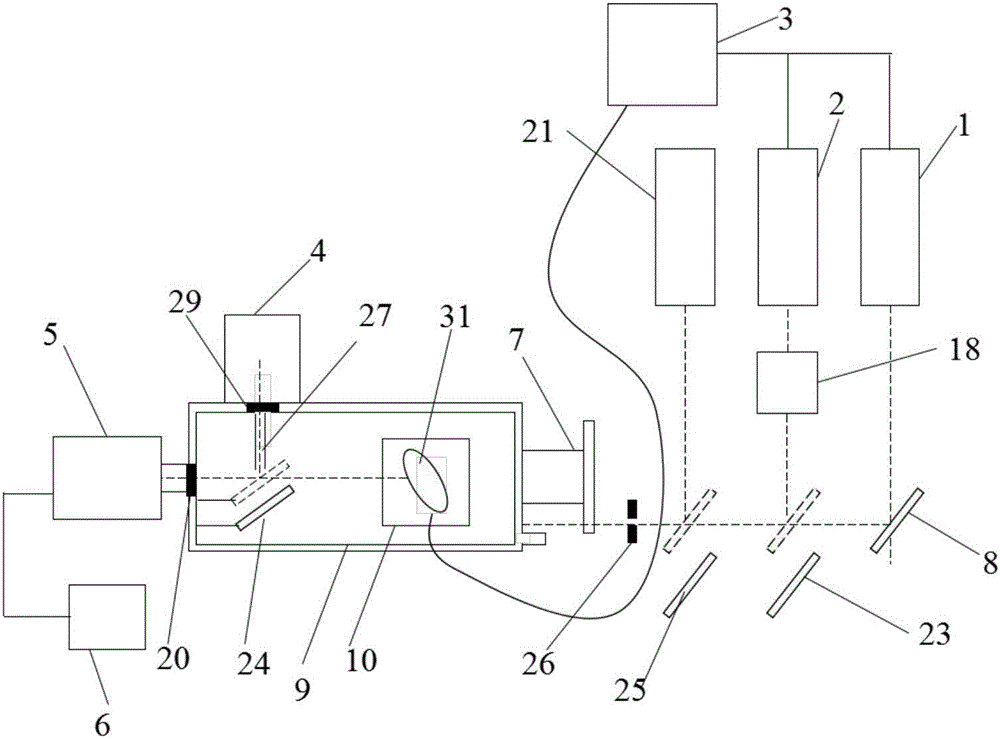

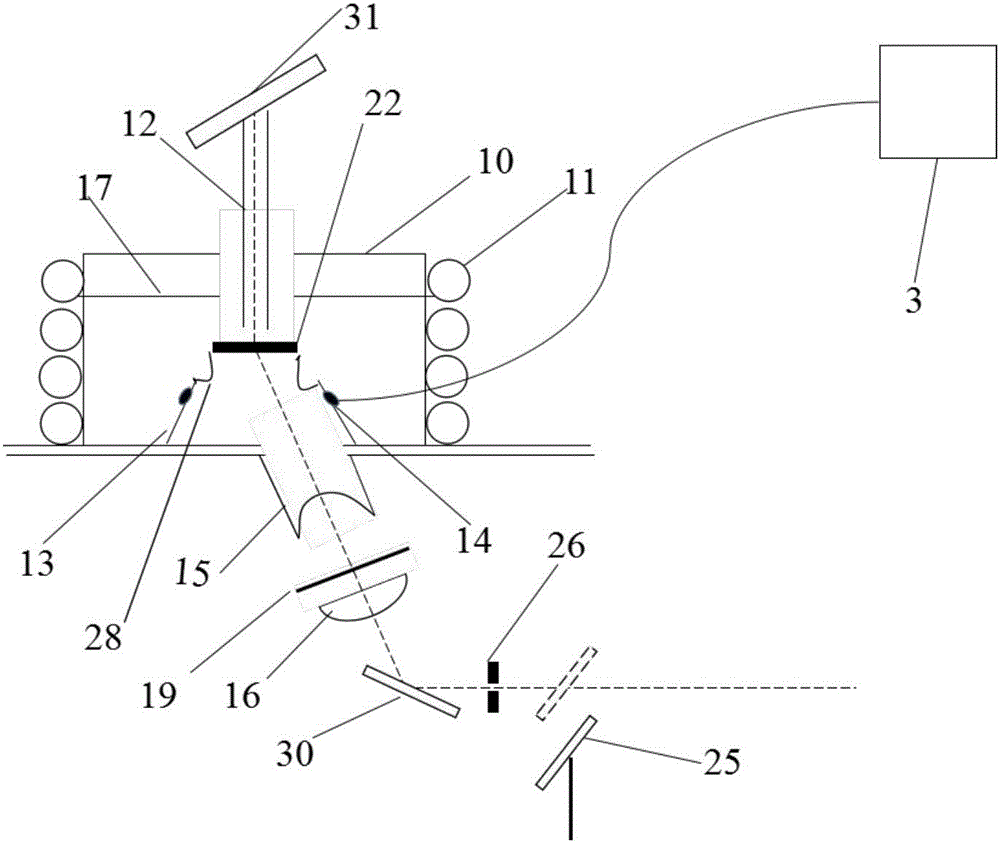

[0031] like figure 1 and 2 As shown in the figure, it can be seen from the figure that the infrared transparent material normal spectral emissivity test device of the present invention includes a sample heating and temperature control subsystem, a vacuum sealing subsystem, a Fourier transform infrared spectrometer 5, a computer 6 and a standard black body 4; the sample The heating and temperature control subsystem includes CO for heating 2 Laser 1, heating optical path, and CO2 The He-Ne laser 21 for calibration and the third movable mirror 25 are placed in parallel with the laser 1; the high temperature and low radiation sample chamber includes a brass wall 10, a cooling copper tube 11 installed around the high temperature and low radiation sample chamber, and the interior The optical baffle 17 above, the aluminum rod frame 13 and platinum wire 28 fixed on the metal sealing chamber 9 for supporting the sample, and the platinum-rhodium thermocouple 14 mounted on the aluminum ...

Embodiment 2

[0044] The difference between this embodiment 2 and embodiment 1 is:

[0045] The sample to be tested 22 is a long-wave infrared transparent material.

[0046] Replace the beam expander lens 15 of the laser beam space shaping part with CaF 2 The beam expander lens made of material is fixed on the screw hole under the metal sealing cavity 9 .

[0047] The above-mentioned measurement step 4 is changed to: move the first movable mirror 23 to the described heating optical path, so that the laser light emitted by the 1064nm ultraviolet laser 2 passes through the 1064nm laser light emitted by the described ultraviolet laser 2 through the described 3 times. The frequency converter obtains a 355nm laser, and the first movable mirror 23 reflects the 355nm laser into the heating optical path, heats the sample to be tested, and then measures;

[0048] The present invention first utilizes CO at two different wavelengths 2 For laser 1 and ultraviolet laser 2, as long as the first movabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com